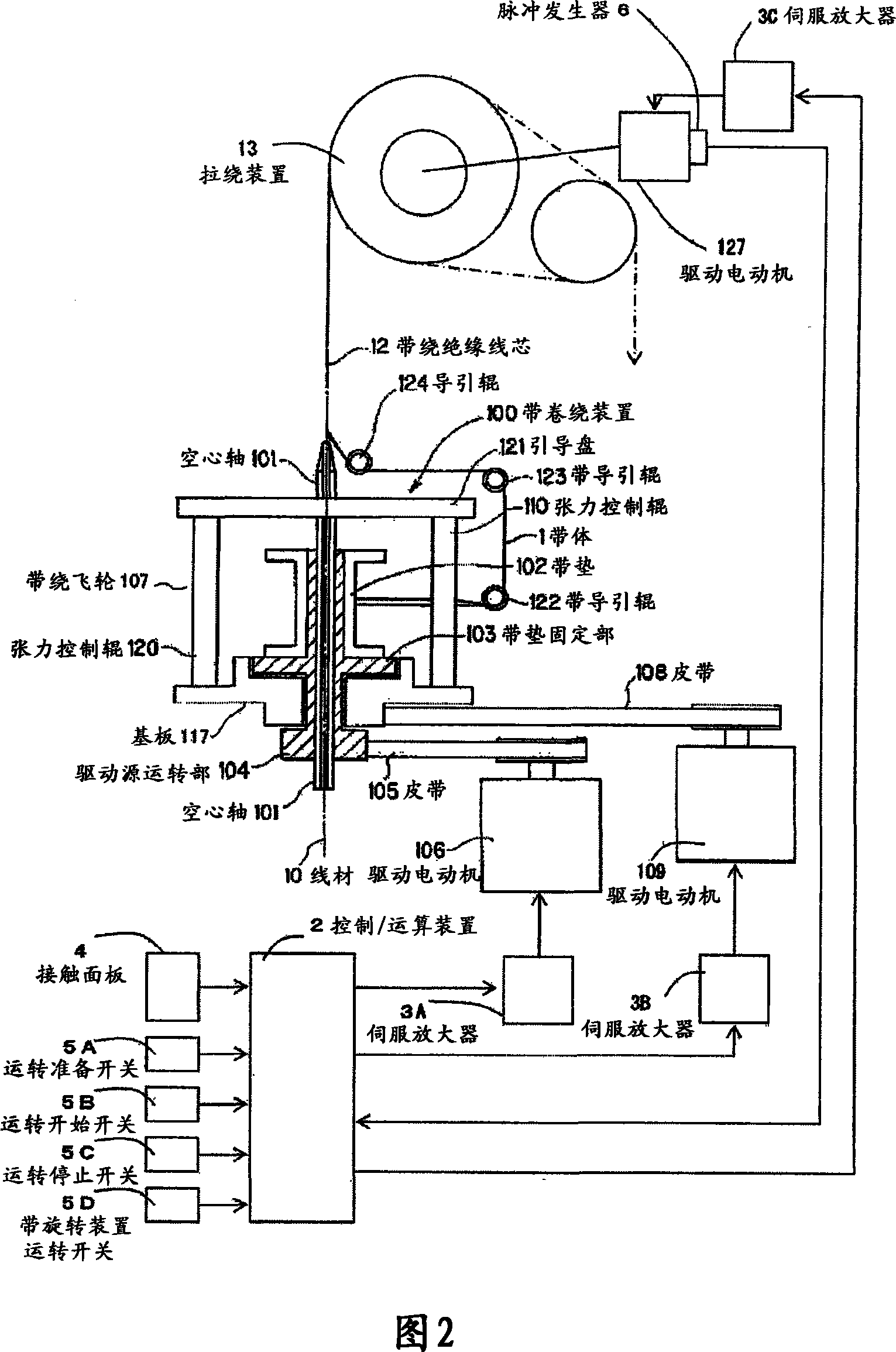

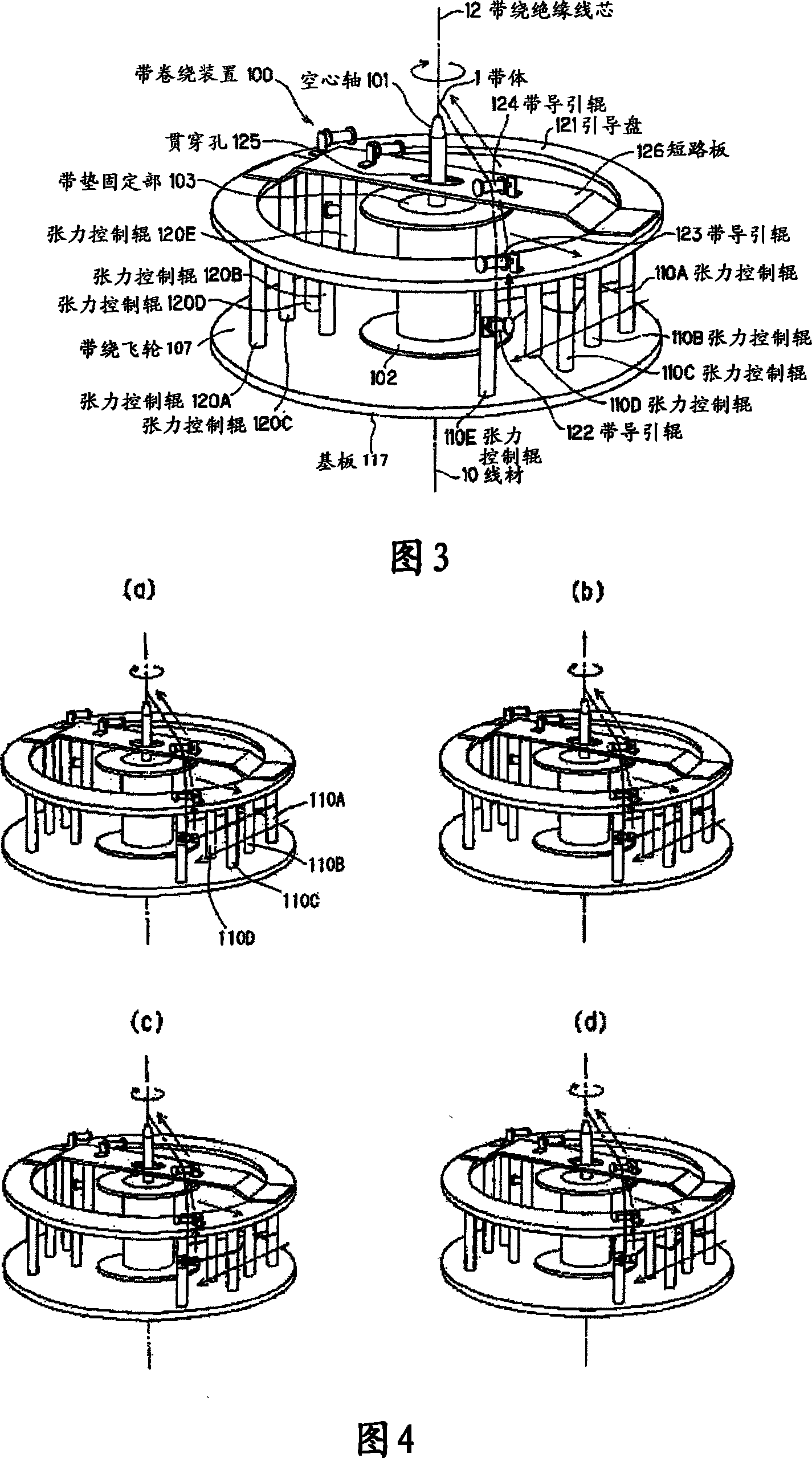

Apparatus for manufacturing taped insulated conductor and method of controlling tape winding tension

A technology for insulated wire cores and manufacturing devices, which is applied in rope-making auxiliary devices, cable/conductor manufacturing, conductor/cable insulation, etc., can solve the problems of easy change, unstable tension, large contact area, etc., and eliminate breakage , to eliminate the effects of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] FIG. 6 is a graph showing the relationship between the length of the belt body 1 (belt length), the shaft torque constant value, and the belt pull-out tension. Utilize the touch panel 4, as the initial torque setting of the driving motor 106, as a value balanced with the zero tension of the gradually decreasing value, the input shaft torque constant value is 100.00 and the belt length of the belt body 1 is 900m. In addition, as the setting of the rotational speed value of the drive motor 109, the rotational speed value of the tape winding flywheel 107 is inputted as 1500 rpm, and 10000 m is inputted as the length value of the winding rod. In addition, the product winding pitch setting value of 6.6mm is also input. In addition, 200m and 60.00 are respectively input as the strip length value and the end torque value of the first stage of the drive motor 106 as the section of the belt body 1 of the first stage, and the strip length value is used as the section of the belt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foaming ratio | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com