Down-hole coal excavation apparatus

A technology of equipment and shearer, applied in the field of coal mining equipment, can solve the problems of high roadway consumption rate, low coal discharge efficiency, and shortened service life of the chute, so as to reduce the labor intensity of workers, improve the degree of automation, and increase the safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

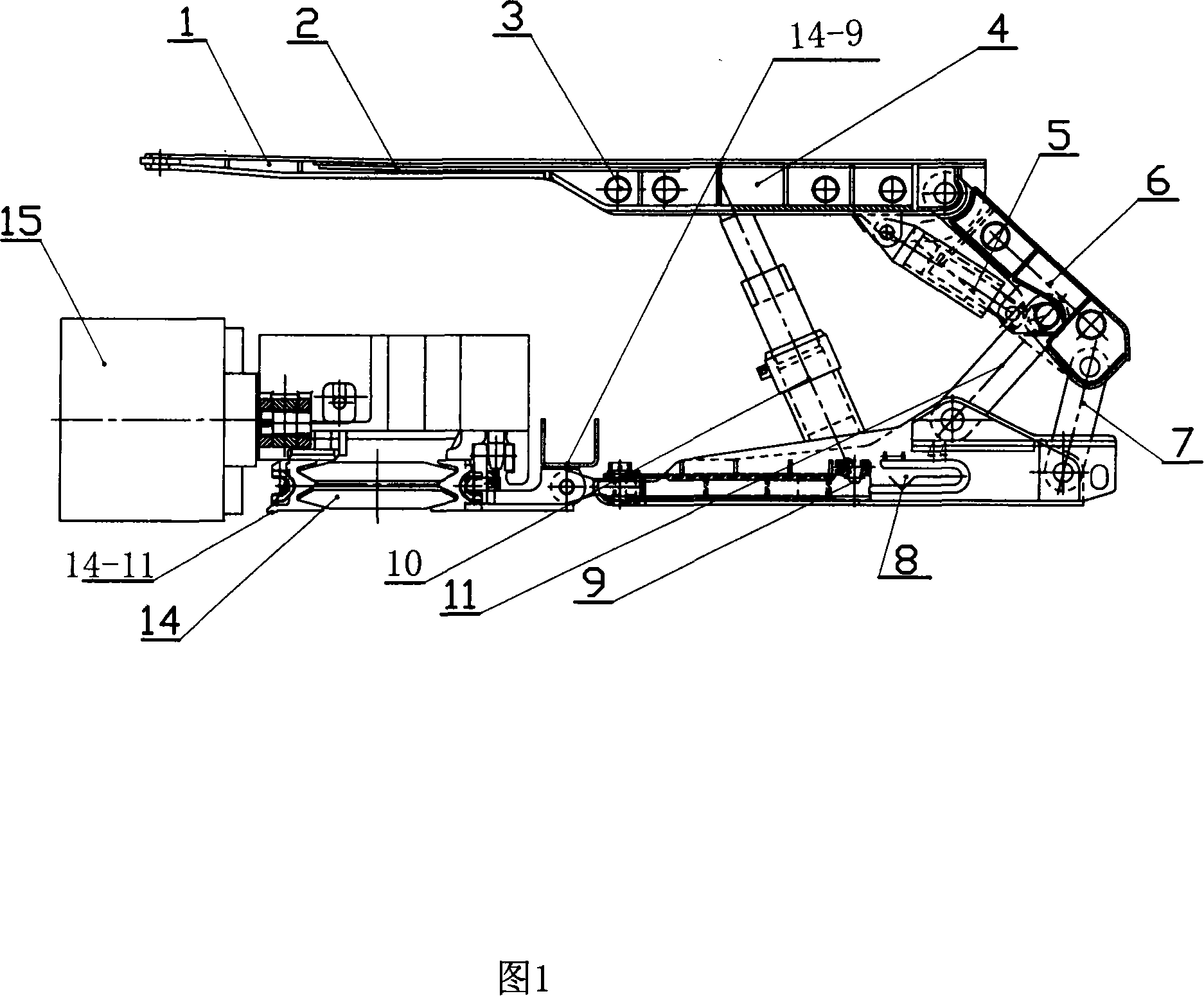

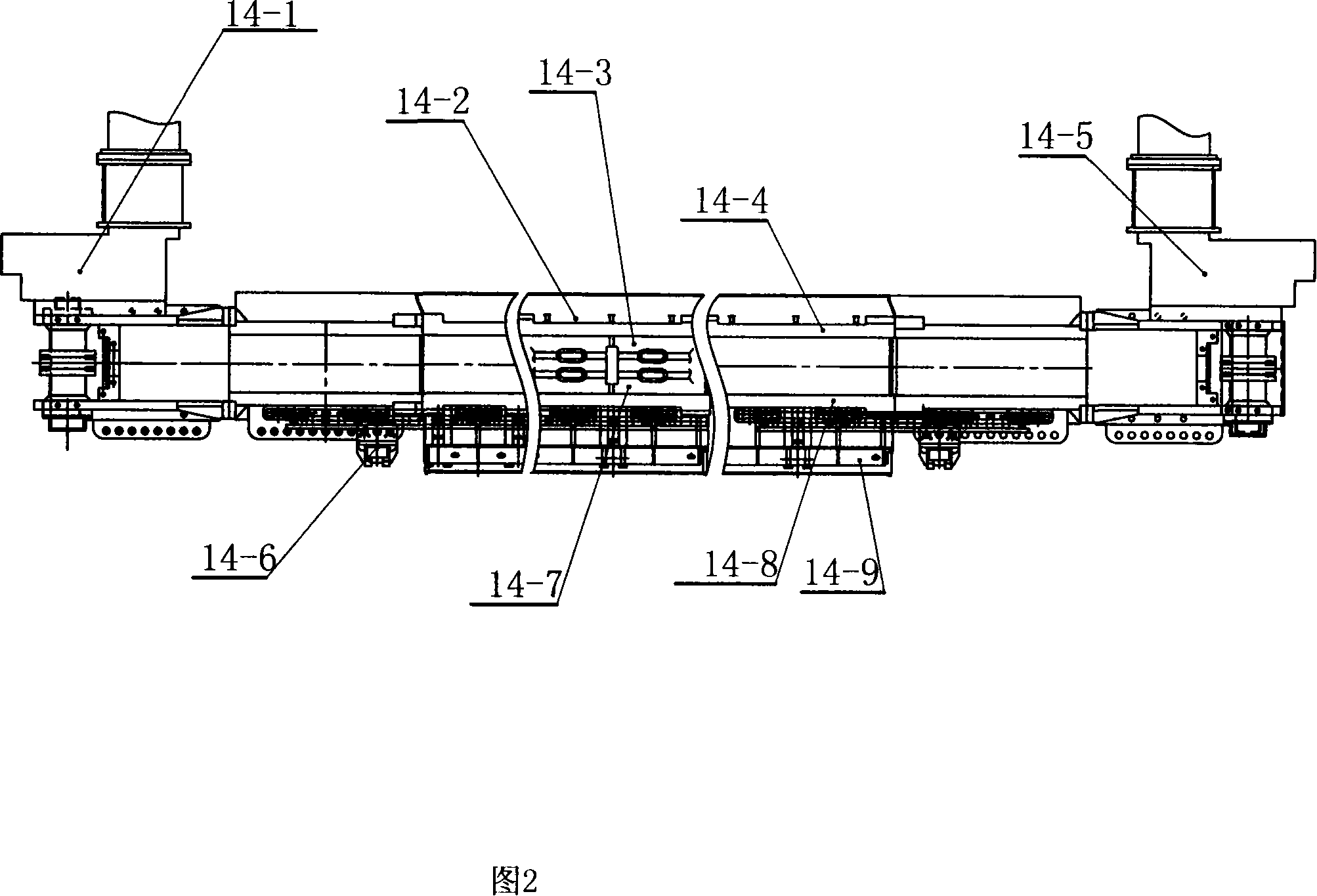

[0019]An underground coal mining equipment, as shown in Figures 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, and 11, which includes: a coal mining machine 15, a scraper conveyor 14, an electro-hydraulic control Thin coal seam shielding type hydraulic support; shearer 15 is a common drum shearer, and shearer 15 includes: drum, motor, hydraulic system of shearer, spray dust suppression system of shearer, left roller, right gear; motor Drive the drum to rotate for coal mining, and the motor drives the left roller and the right gear to rotate to make the shearer move back and forth on the scraper conveyor; the scraper conveyor 14 includes a head power unit 14-1, a commonly used tail power unit 14- 5. Commonly used nose pushing frame 14-6, commonly used machine tail pushing frame, commonly used machine tail transition groove, multiple chutes 14-3, cable groove 14-9, dumbbell pin 14-10, commonly used racks, Sprocket, scraper, scraper chain, head power unit 14-1 is provided with reducer, connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com