Sand leaf-disk for machining metal workpiece

A technology for metal workpieces and sand discs, which is applied to metal processing equipment, wheels with flexible working parts, manufacturing tools, etc. It can solve the problems of insufficient recycling of resources, high manufacturing and use costs, and unaffordable costs for users. problems, to achieve good rigidity, strong integrity, and reduce thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] As shown in Figures 1, 2, and 3, the abrasive disc for processing metal workpieces is composed of a substrate 1 and an abrasive cloth sheet 2, and the abrasive cloth sheet 2 is adhered to the inner ring of the substrate 1 in a radial manner by an adhesive. On the surface, the base 1 is an integral stamped metal component stamped from a cold-rolled steel sheet. The thickness of the cold-rolled steel sheet of the metal component is 0.2mm. The center of the base 1 is stamped with a pit 4 with a mounting hole 3. Bonding The face is flat.

Embodiment 2

[0038] As shown in Figures 1, 2, and 3, the abrasive disc used for processing metal workpieces is composed of a substrate 1 and an abrasive cloth sheet 2, and the abrasive cloth sheet 2 is adhered to the inner ring surface of the substrate in a radial manner by an adhesive Above, the base 1 is an integral stamped metal component stamped from a cold-rolled steel sheet. The thickness of the cold-rolled steel sheet of the metal component is 1.5 mm. The center of the base is stamped with a pit with a mounting hole, and the bonding surface is processed into a rough surface. flat.

Embodiment 3

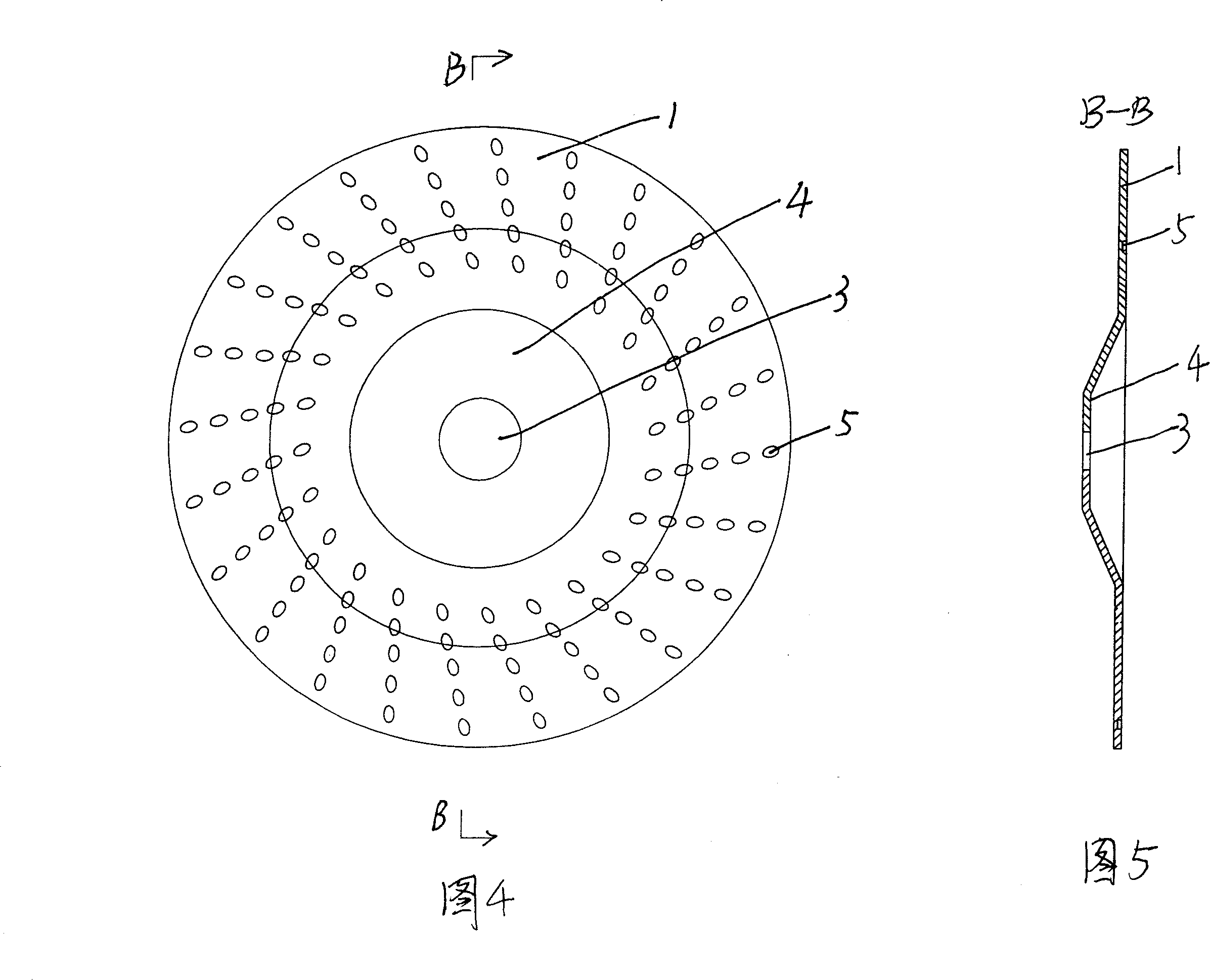

[0040] As shown in Figures 1, 4, and 5, the abrasive disc for processing metal workpieces is composed of a substrate 1 and an abrasive cloth sheet 2, and the abrasive cloth sheet 2 is adhered to the inner ring of the substrate 1 in a radial manner by an adhesive. On the surface, the base body is an integral stamped metal component stamped from a hot-rolled steel sheet, the thickness of the metal component sheet is 2.5 mm, and the center of the base body is stamped with a pit 4 with a mounting hole 3. A stamped groove structure for holding the adhesive is arranged. The grooves are small round grooves evenly distributed on the bonding surface, such as millet word grooves, small cross grooves, small Z grooves or small S grooves, and the grooves are arranged in a radial shape. In this embodiment, small round grooves with star cloth are used 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com