Active type safety syringe and safety injection needle

A technology for safe syringes and safe injections, applied in the direction of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of increased manufacturing costs, difficulties in mold manufacturing, and uneven processing, so as to increase competitiveness and value, use convenience, and performance The effect that the price ratio stands out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

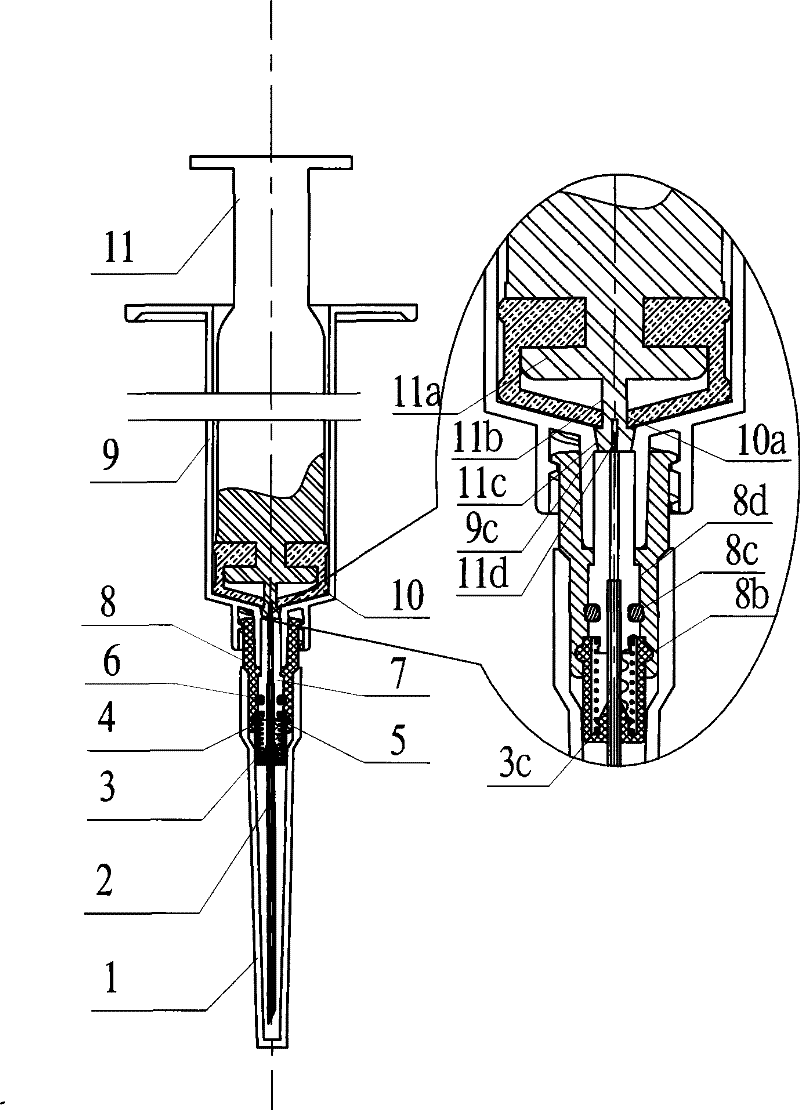

[0022] In order to better understand the technical solution of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

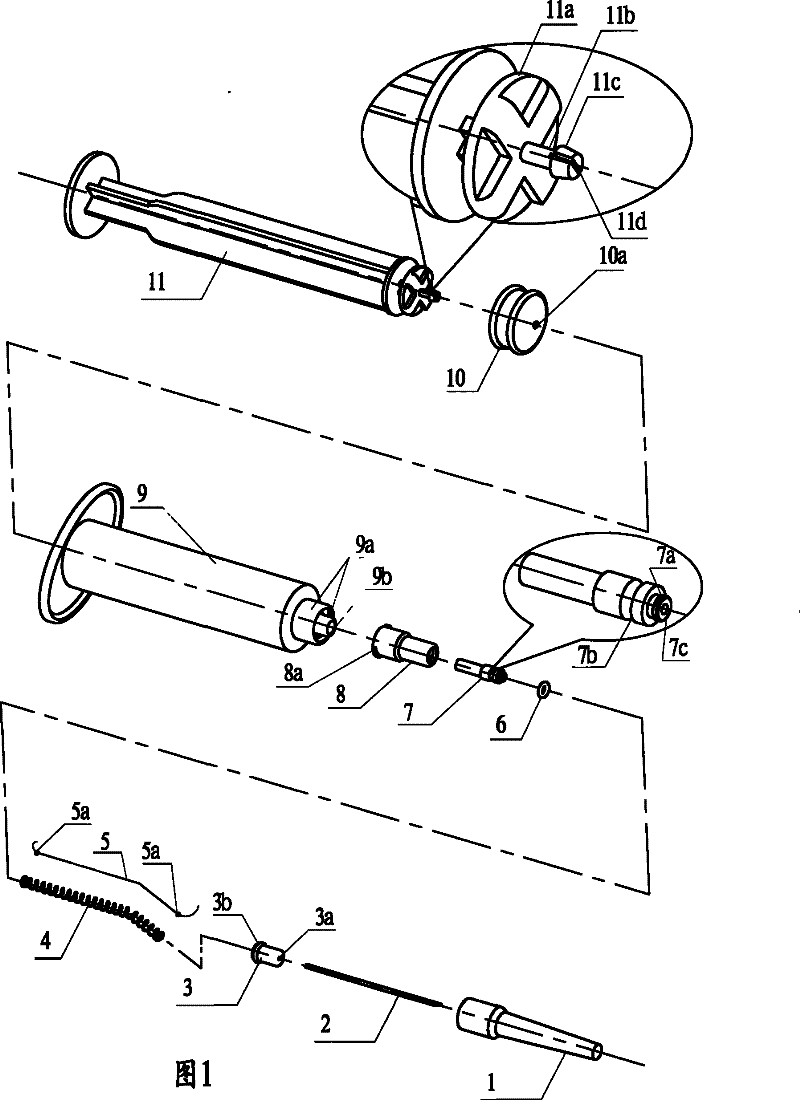

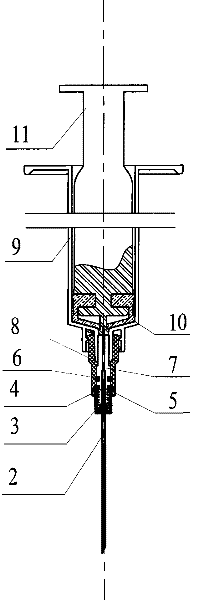

[0023] Depend on figure 1 It can be seen that the present invention is composed of two parts, a safety syringe and a safety injection needle. The safety injection needle part is composed of an injection needle protection jacket 1, an injection needle 2, a needle tip protection sleeve 3, a protection spring 4, a limit cable 5, a sealing ring 6, The needle seat 7 and the outer Luer interface 8 are composed; the safety syringe part is composed of the outer cylinder 9 , the push rod 11 and the sealing rubber plug 10 . Wherein: there is a hole 3a at the front end of the needle point protection sleeve 3, which is convenient for the injection needle 2 to pass through, and the outer edge of the rear end of the needle point protection sleeve 3 is formed with an annular protrusion 3b; With the ball knot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com