Method of producing lactic acid bacterium having antiallergic effect

A manufacturing method and technology of lactic acid bacteria, which can be applied to medical preparations containing active ingredients, microorganism-based methods, allergic diseases, etc., can solve the problems of lack of anti-allergic activity, no research on the relationship between anti-allergic effects of lactic acid bacteria, etc. Reduced culture cost, excellent anti-allergic effect, and inhibitory effect on IgE production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

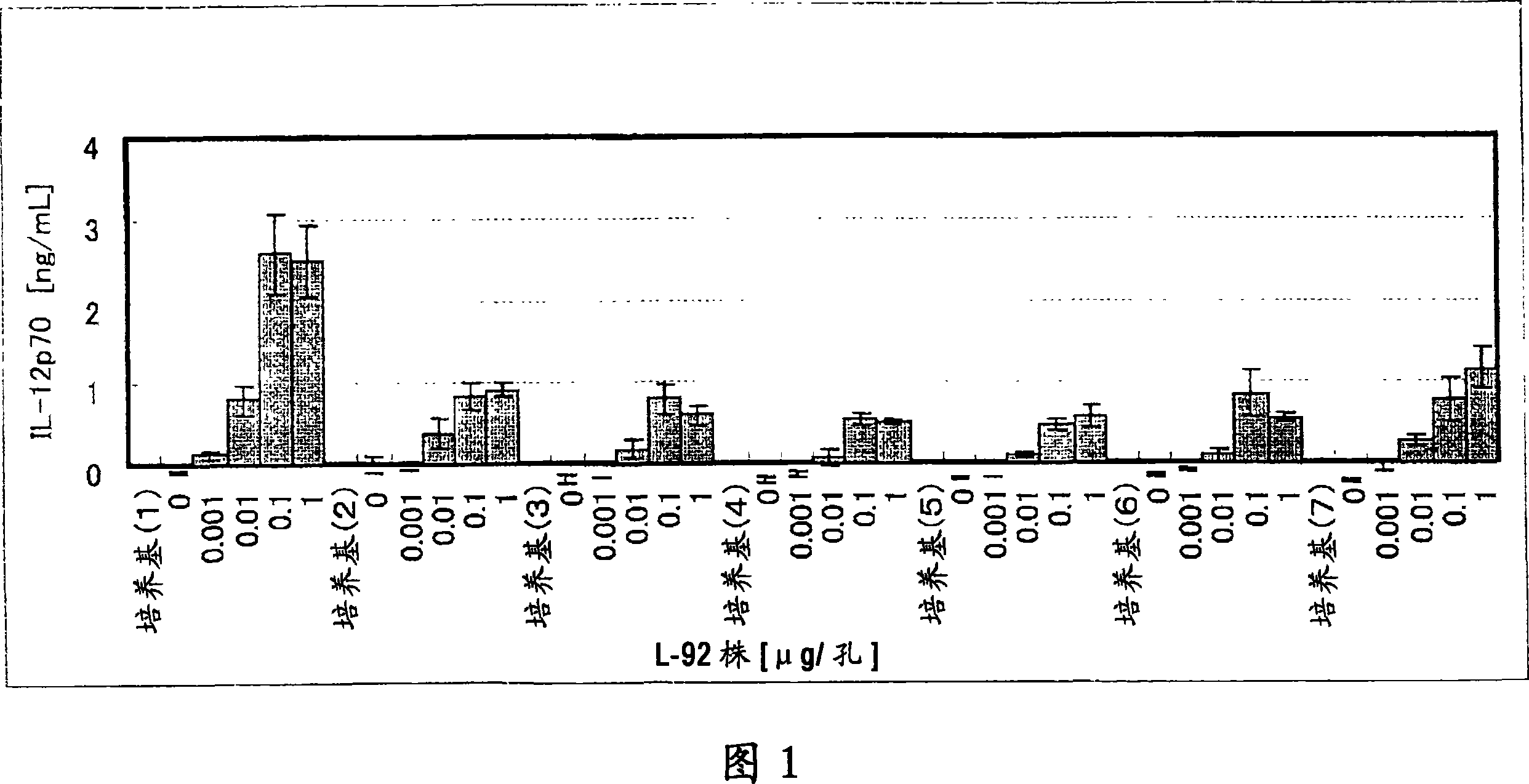

Embodiment 1

[0044] Prepare media using Casein Peptone Plus

[0045] In 10g of fish meat extract (trade name: Ehrlich's meat extract, manufactured by Kukuto Pharmaceutical Industry), 5g of yeast extract (trade name: MEAST P2G, manufactured by ASAHI-FH), 20g of glucose, 1g of mono-oil Decapolyglyceride (trade name: Polyglycerinester POEME J-0381V, manufactured by Riken Vitamin), 5g sodium acetate crystal (food additive specification standard), 0.1g magnesium sulfate crystal (food additive specification standard) and 2g dipotassium hydrogen phosphate ( Add 10 g of casein peptone (trade name: CaseinPeptone Plus, manufactured by Organotechnie) to food additive specification standards), add purified water, quantify to 1 L, adjust the pH to 6.8 with sodium hydroxide, and place in an autoclave at 121°C Sterilize in medium for 20 minutes to prepare culture medium 1).

Embodiment 2

[0075] Tablet preparation

[0076] Add 1 kg of casein peptone (trade name: Casein Peptone Plus, manufactured by Organotechnie), 0.5 kg of yeast extract (trade name: yeast peptone standard type FORganotechnie), 2.25 kg of sucrose, and 0.1 kg of decaglycerol monooleate (trade name : SUNSOFT Q-17S, manufactured by Taiyo Chemical), 0.5kg sodium acetate crystal (food additive standard), 0.5kg dipotassium hydrogen phosphate (food additive standard), 0.1kg magnesium sulfate crystal (food additive standard) 1kg fish meat extract (trade name: Bacterio-N-KS (B), manufactured by MARUHA), add purified water, quantify to 100L, and adjust to pH 6 with about 50% sodium hydroxide dissolved (food additive specification standard). 8. After sterilizing at 121°C for 20 minutes according to the usual method, cool down to the culture temperature of 35°C to prepare the culture medium.

[0077] Aseptically inoculate 1 to 5% of the primers cultured at 35°C using the same medium, stir for 15 minutes, ...

Embodiment 3

[0082] manufacturing of beverages

[0083] Add 1 kg of casein peptone (trade name: Casein Peptone Plus, manufactured by Organotechnie), 0.5 kg of yeast extract (trade name: Yeast Peptone Standard Type F, manufactured by Organotechnie), 2.25 kg of sucrose, and 0.1 kg of decaglycerol monooleate (trade name: SUNSOFT Q-17S, manufactured by Sun Chemical), 0.5kg sodium acetate crystal (food additive standard), 0.5kg dipotassium hydrogen phosphate (food additive standard), 0.1kg magnesium sulfate crystal (food additive standard) specifications), 1kg fish extract (trade name: Bacterio-N-KS(B), manufactured by MARUHA), add purified water, measure to 100L, adjust to pH 6.8 with about 50% sodium hydroxide, and Methods After sterilizing at 121°C for 20 minutes, cool down to the culture temperature of 35°C to prepare the culture medium.

[0084] Aseptically inoculate 1 to 5% of the primers cultured at 35° C. using the same medium, stir for 15 minutes, stop the stirring blades, and culture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com