Method for anti-floating of underground building

A technology for underground buildings and scuppers, applied in construction, protection devices, infrastructure engineering, etc., can solve the problems of high cost, great difficulty, long construction period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

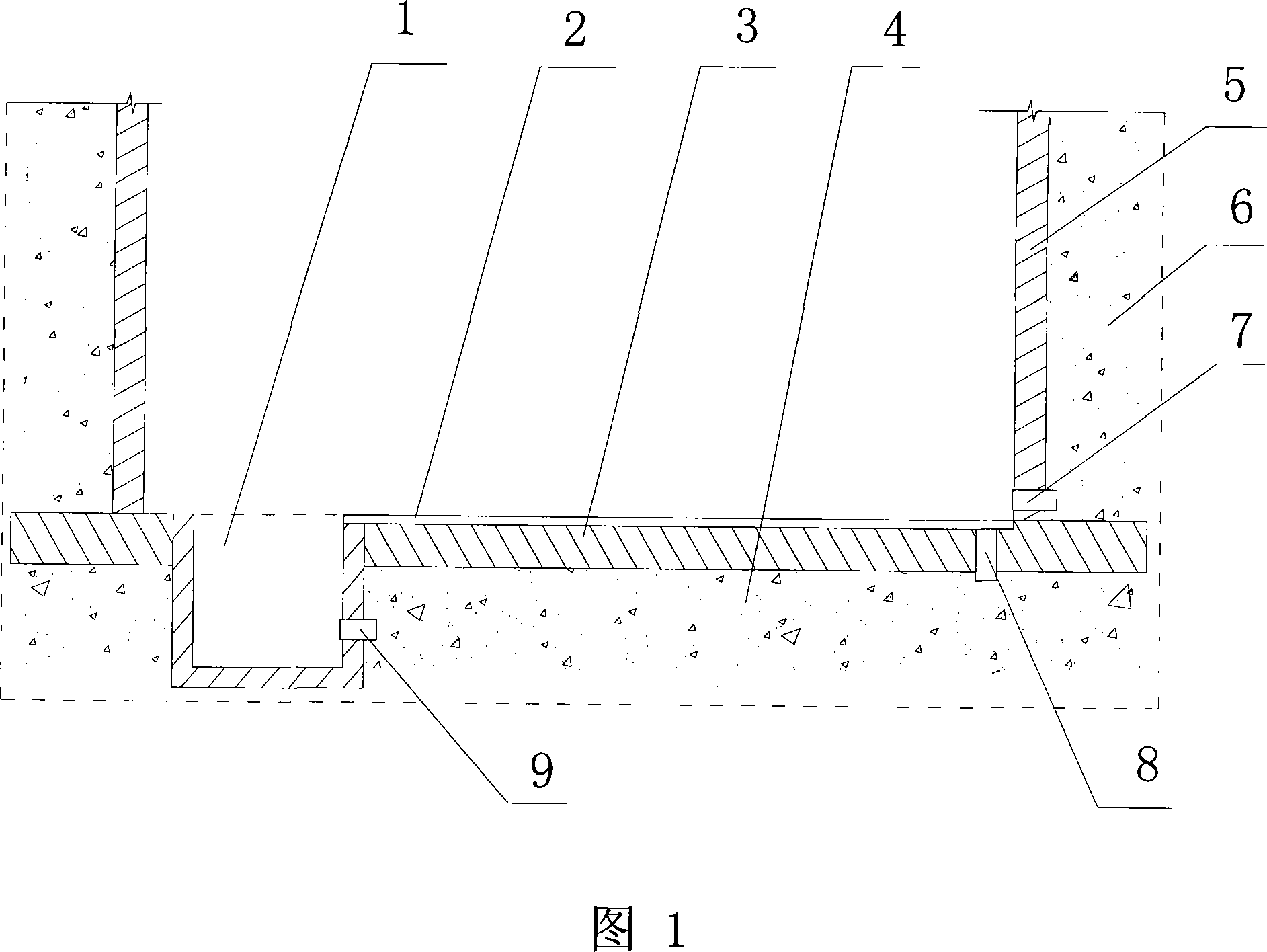

[0037] A method for anti-floating of underground buildings, 1) first water discharge hole 7 is set at the bottom of underground building outer wall 5 (new construction is to reserve the first water discharge hole 7, and built project is to excavate the first water discharge hole 7), the diameter of the first drain hole 7 is 80-120mm, the first drain hole 7 is provided with a replaceable filter device, the replaceable filter device includes a graded sand filter layer and an indoor side Sealing filter device on the hole (such as steel wool, polyolefin foam, etc.);

[0038] One end of the first weep hole 7 communicates with the indoor drainage groove 2 of the underground building (if the original drainage groove is inappropriate, a new drainage groove can be added), and the other end of the first weep hole 7 is located outside the underground building Outside the wall 5 (groundwater in the outdoor filling 6 flows into the drainage ditch 2 through the first weep hole 7);

[0039]...

Embodiment 2

[0044] A method for anti-floating of underground buildings, 1) second scupper holes 8 are set on the bottom plate of underground buildings ), the diameter of the second drain hole 8 is 80-120mm, the second drain hole 8 is provided with a replaceable filter device, the replaceable filter device includes a graded sandstone filter layer and an indoor side hole Sealed filter device (such as steel ball, polyolefin foam, etc.);

[0045] The upper end of the second drain hole 8 communicates with the indoor drainage groove 2 of the underground building (as the original drainage groove position is improper, a new drainage groove can be added), and the lower end of the second drain hole 8 is located at the base plate of the underground building 3 Down (groundwater in the base soil 4 flows into the drainage ditch 2 through the second weep hole 8);

[0046] The diameter and quantity of the second weep hole 8 are calculated and determined according to the specific conditions of the projec...

Embodiment 3

[0050] As shown in Figure 1, a kind of anti-floating method of underground building, 1) the first scoop hole 7 is set in the bottom of underground building outer wall 5 (new project is to reserve the first scoop hole 7, built project It is to excavate the first weep hole 7), the diameter of the first weep hole 7 is 80-120mm, the first weep hole 7 is provided with a replaceable filter device, the replaceable filter device includes graded sand The stone filter layer and the sealing filter device (such as steel ball, polyolefin foam, etc.) on the indoor side hole; one end of the first weep hole 7 communicates with the indoor drainage groove 2 of the underground building (if the original drainage groove is not properly located , can add drainage ditch), the other end of the first weep hole 7 is located outside the exterior wall 5 of the underground building (the groundwater in the outdoor filling soil 6 flows into the drainage ditch 2 through the first weep hole 7);

[0051]The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com