Section bar of curtain wall of heat insulation aluminum alloy

A technology of aluminum alloys and profiles, applied in walls, building components, insulation, etc., can solve problems such as high cost, falling off of heat-insulating profiles, and increased building weight, and achieve the effects of increasing service life, improving safety performance, and reducing resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

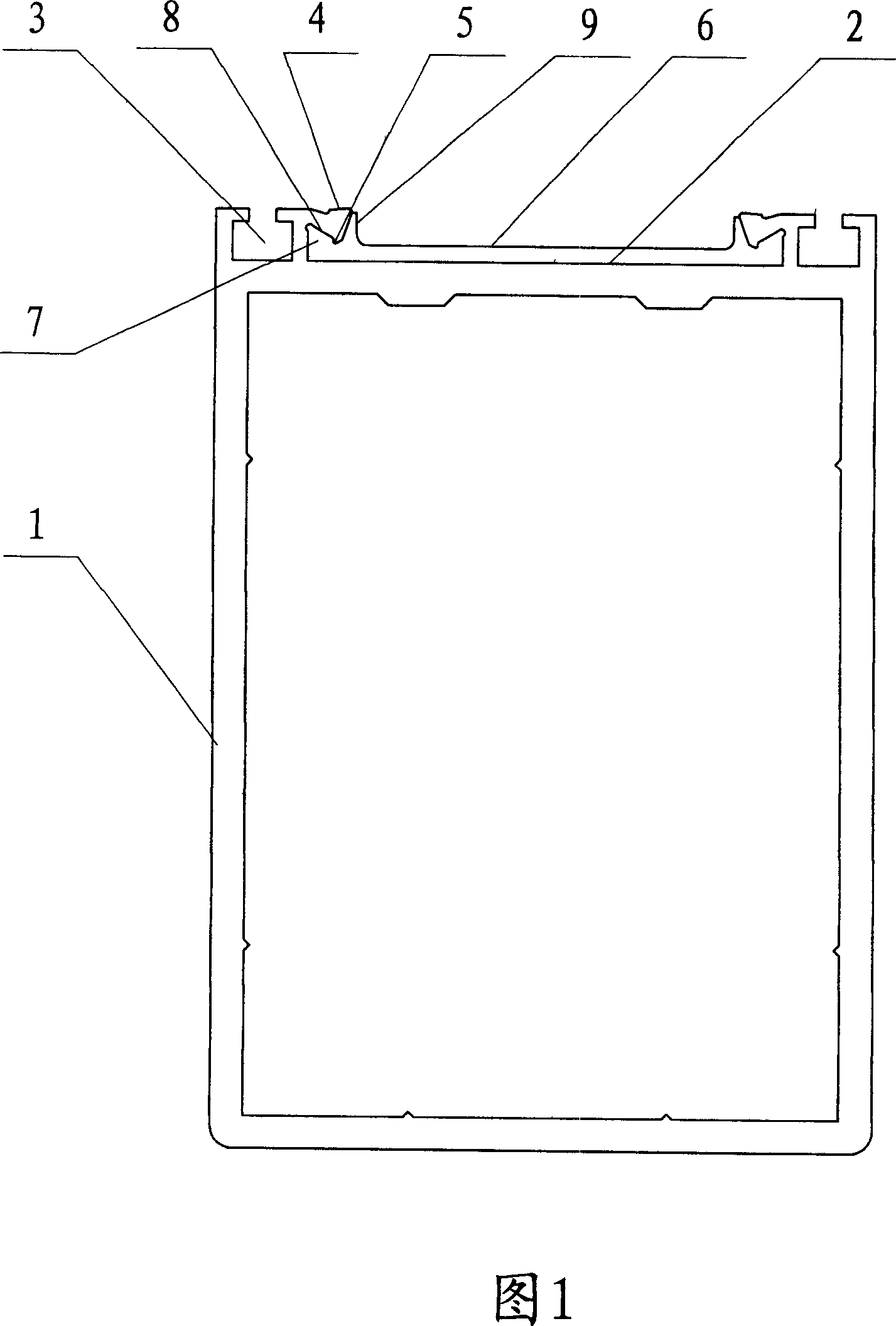

[0018] The structural diagram of a one-shaped heat-insulating aluminum alloy curtain wall profile is shown in Figure 1, where 1 is the aluminum alloy curtain wall profile, 2 is the aluminum alloy front beam, 3 is the sealing strip inlay groove, 4 is the upper pressing plate of the card groove, and 5 is the card Pressing plate boss on the groove, 6 is a straight heat-insulating profile, 7 is an anti-off boss, 8 is an anti-off slope, and 9 is an end heat-insulation boss. When assembling, insert the two ends of the inline heat-insulating profile 6 into the opening grooves at the two ends of the aluminum alloy front beam 2 respectively, and the rolling machine presses the upper pressing plate 4 of the slot and the upper pressing plate of the slot The table 5 is pressed into the triangular groove formed by the anti-off boss 7 and the end heat insulation boss 9, and the heat insulation profile 6 and the aluminum alloy curtain wall profile 1 are combined together.

Embodiment 2

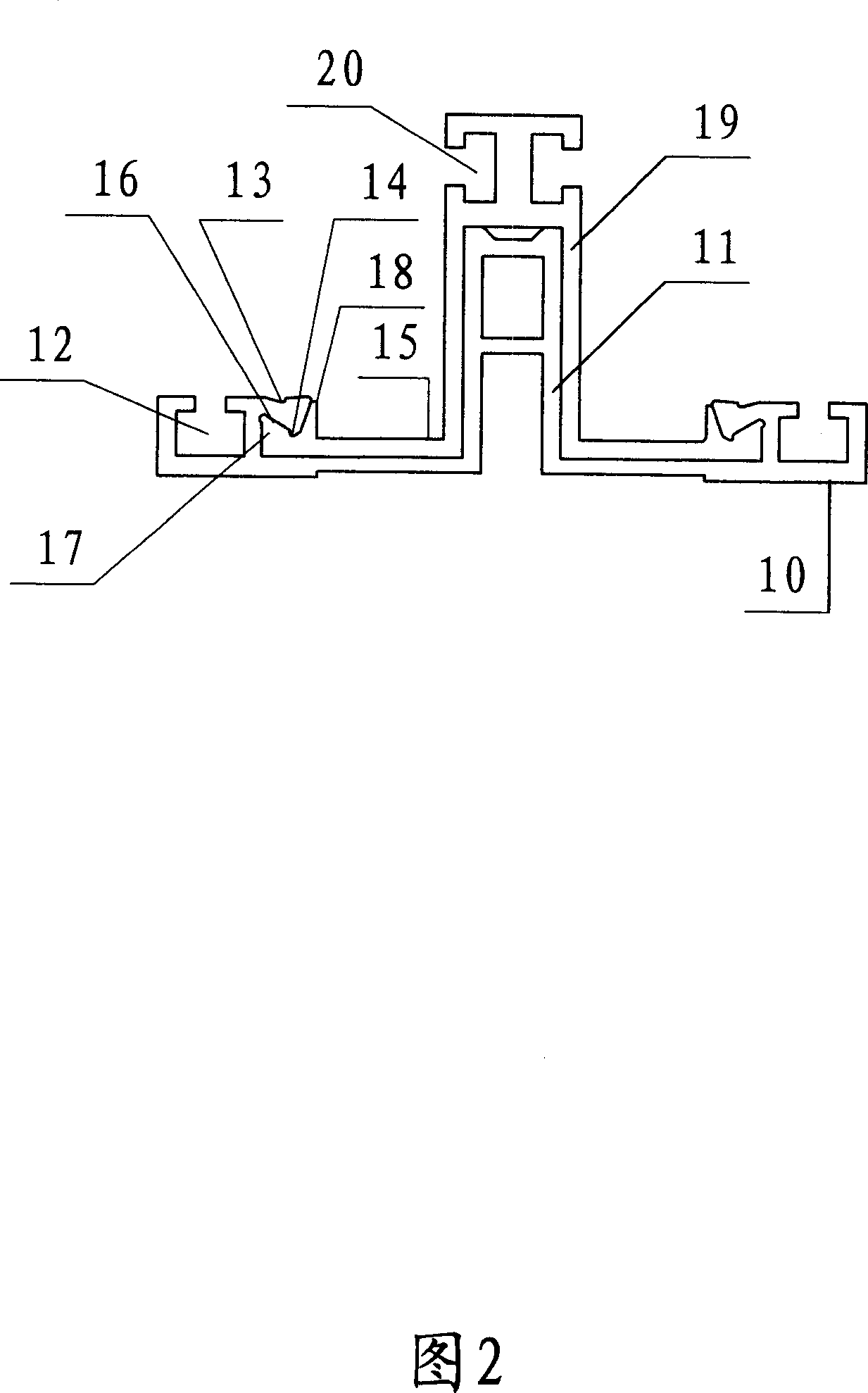

[0020] A structural diagram of a heat-insulating aluminum alloy curtain wall profile of a T-shaped support plate is shown in Figure 2, wherein 10 is an aluminum alloy curtain wall profile, 11 is an aluminum alloy T-shaped support plate, 12 is a sealing strip inlay groove, and 13 is an upper pressure plate. 14 is the boss of the upper platen, 15 is the T-shaped hollow heat insulation profile, 16 is the anti-slip surface, 17 is the anti-slip boss, 18 is the end heat insulation boss, 19 is the support plate of the heat insulation profile, and 20 is the sealing strip Mosaic slot. When assembling, insert the T-shaped heat-insulating profile 15 with the heat-insulating profile support plate 19 into the opening grooves at the two ends of the aluminum alloy upper platen respectively, and the rolling machine will fit the groove on the The pressing plate 13 and the upper pressing plate boss 14 of the card slot are pressed into the triangular groove formed by the anti-off boss 17 and the...

Embodiment 3

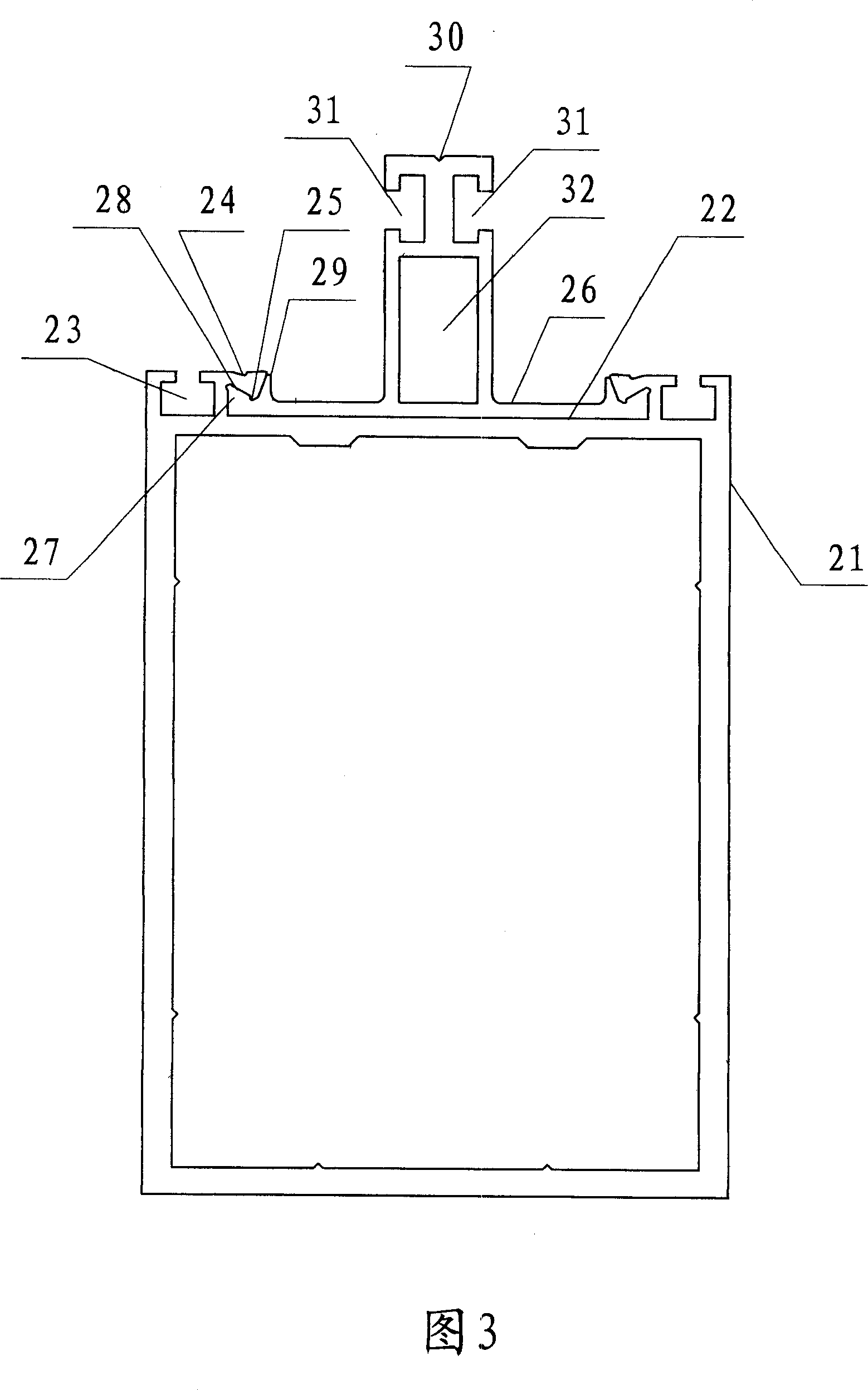

[0022] A structural diagram of a heat-insulating aluminum alloy curtain wall profile with sealing strip inlay grooves on both sides of the T-shaped support plate is shown in Figure 3, wherein 21 is an aluminum alloy curtain wall profile, 22 is an aluminum alloy front beam, and 23 is a sealing strip inlay groove. 24 is the upper pressure plate of the card slot, 25 is the boss of the upper pressure plate of the card slot, 26 is the inlay groove heat insulation profile with sealing strip, 27 is the anti-off boss, 28 is the anti-off slope, 29 is the end heat insulation boss , 30 is a heat-insulating profile support plate, 31 is a support plate sealing strip inlay groove, and 32 is a closed mouth of the support plate. When assembling, insert the anti-off protrusions 27 at the two ends of the heat insulating profile 26 with the heat insulating profile support plate 30 into the opening grooves at the two ends of the aluminum alloy front beam 22 respectively, and roll The press presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com