Composite culture medium for producing lincomycin, and production method for raising output and quality

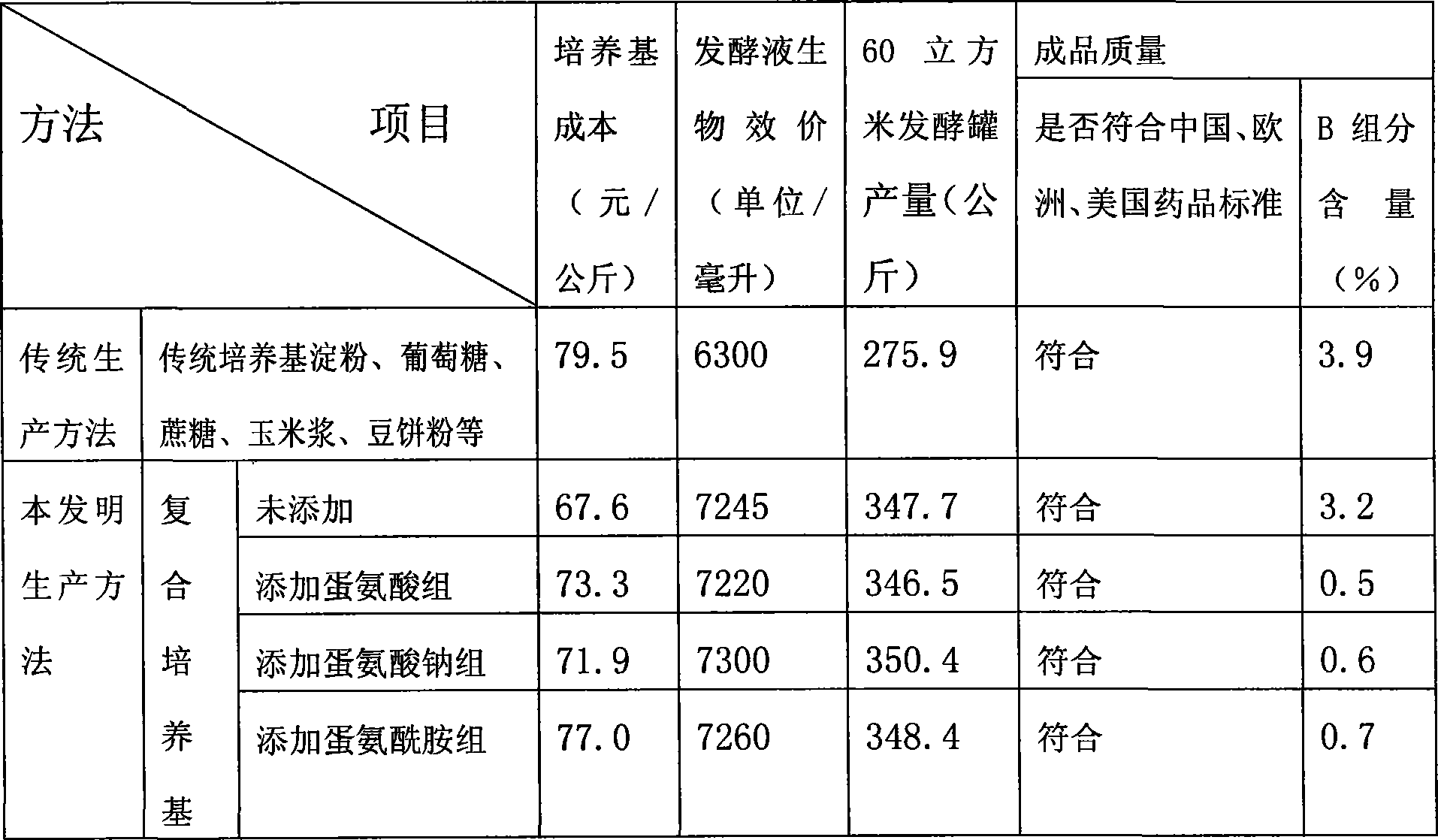

A technology of lincomycin and culture medium, which is applied in the field of compound medium for producing lincomycin, and achieves the effects of less foam, stable quality of finished products, and coordinated, synchronous, stable and efficient production of hormones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

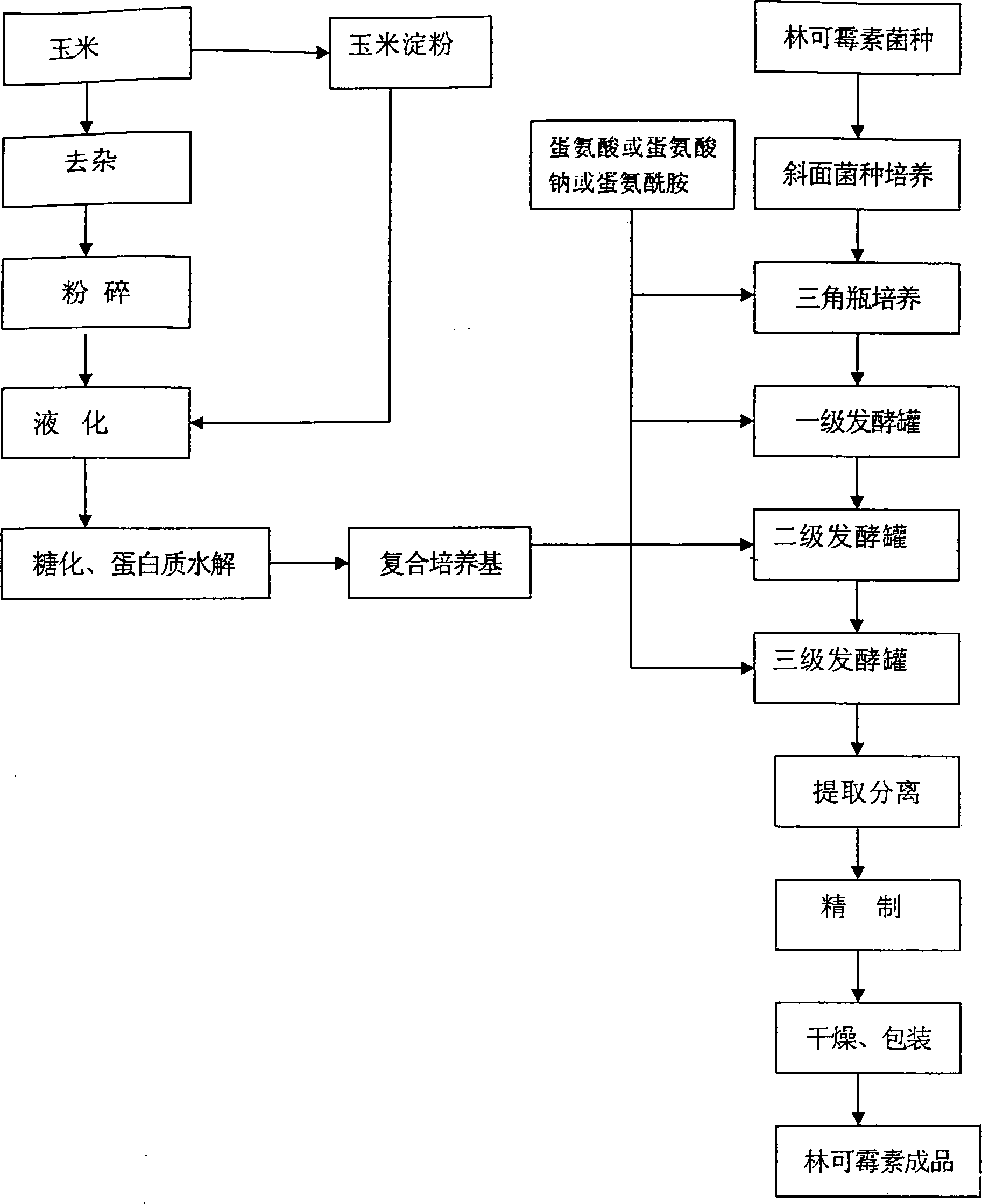

Method used

Image

Examples

preparation example Construction

[0052] The preparation of compound medium is carried out according to the following method steps:

[0053] First, take 2 / 3 of the amount of corn flour, corn starch, calcium lactate, and water to soak in the reaction tank according to the proportion of the formula, and add 2 / 3 of the α-amylase according to the proportion of the formula, and heat up Carry out the first stage of liquefaction at 59-61°C for 2 hours; then take 1 / 3 of the amount of corn flour, corn starch, calcium lactate, and water according to the proportion of the formula and add them to the reaction tank, and then add them according to the proportion of the formula Add 1 / 3 of α-amylase, raise the temperature to 84-86°C for the second stage of liquefaction for 1.5 hours; then lower the temperature of the liquefied liquid to 60°C, add glucoamylase and protease respectively according to the ratio of the formula, and keep warm for 7.5- 8.5 hours; when the reaction solution is viscous and fluid and dark yellow, lower...

Embodiment 1

[0056] The ratio of the composition of the present invention is: 70 kg of corn flour, 30 kg of corn starch, 0.02 kg of α-amylase, 1.0 kg of glucoamylase, 0.0002 kg of protease, 0.20 kg of calcium lactate and 260 kg of water. The prepared compound medium contains the following components: 32% glucose, 40% total sugar, 3.1% nitrogen, and 340 micrograms per milliliter of dissolved phosphorus.

Embodiment 2

[0058] The formula ratio of the present invention can also be: 75 kg of corn flour, 25 kg of corn starch, 0.02 kg of α-amylase, 1.1 kg of glucoamylase, 0.0004 kg of protease, 0.19 kg of calcium lactate and 280 kg of water. The prepared compound medium contains the following components (mass concentration): 33% of glucose, 42% of total sugar, 3.2% of nitrogen, and 360 micrograms per milliliter of dissolved phosphorus.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com