Technique for producing vanadium pentoxide

A technology of vanadium pentoxide and production process, applied in the field of vanadium pentoxide production technology, can solve the problems of large sulfuric acid consumption, immature process conditions, failure to realize industrialized production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

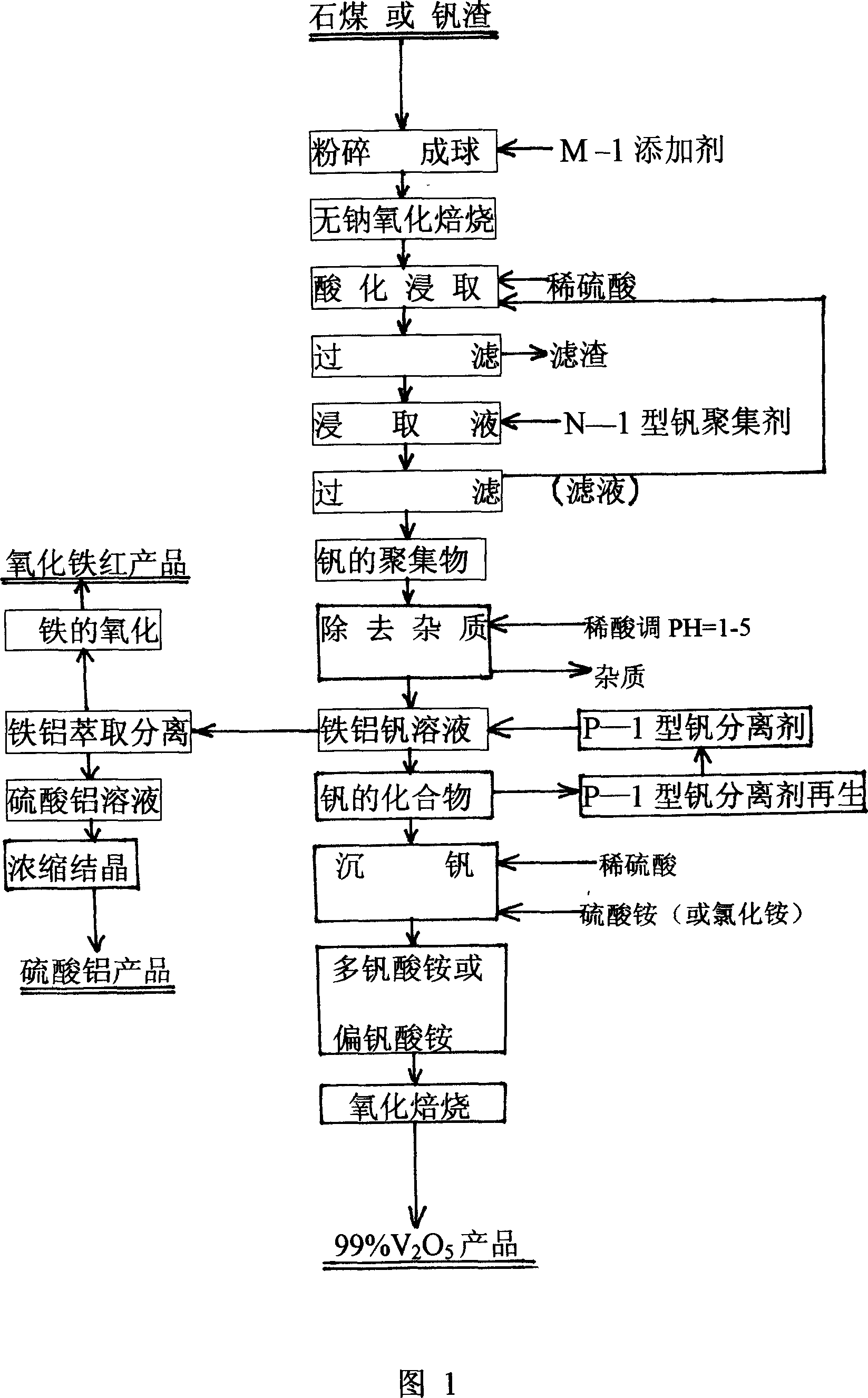

[0005] The present invention is described in further detail now in conjunction with accompanying drawing. Referring to Figure 1, the present invention first crushes stone coal or vanadium slag, adds M-1 additives to form balls, and then puts them into flat kilns or converters for decarburization and oxidative roasting at a temperature of 600-800°C, and the time is 3- 8 hours, then discharge the material, put the decarburized and oxidized stone coal or vanadium slag into the leaching barrel and add dilute sulfuric acid solution for leaching, the leaching solid-liquid ratio is 1:1-2, and the concentration of dilute sulfuric acid is 3%- 15%, the leaching time is 0.5-8 hours, and then filtered, and the filtrate is used for the next vanadium collection process for later use. The filter residue is washed twice, the washing water is combined with the original filtrate, and N-1 vanadium aggregation agent is added to the filtrate to separate the vanadium in the form of vanadium aggrega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com