Failed fuel assemblies repair technology after irradiation

A fuel assembly and damage technology, applied in the direction of reactor fuel elements, nuclear engineering, reactors, etc., can solve the problems of time-consuming, labor-intensive, high risk, and inconvenient operation, and achieve the effect of convenient use, simple tool structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

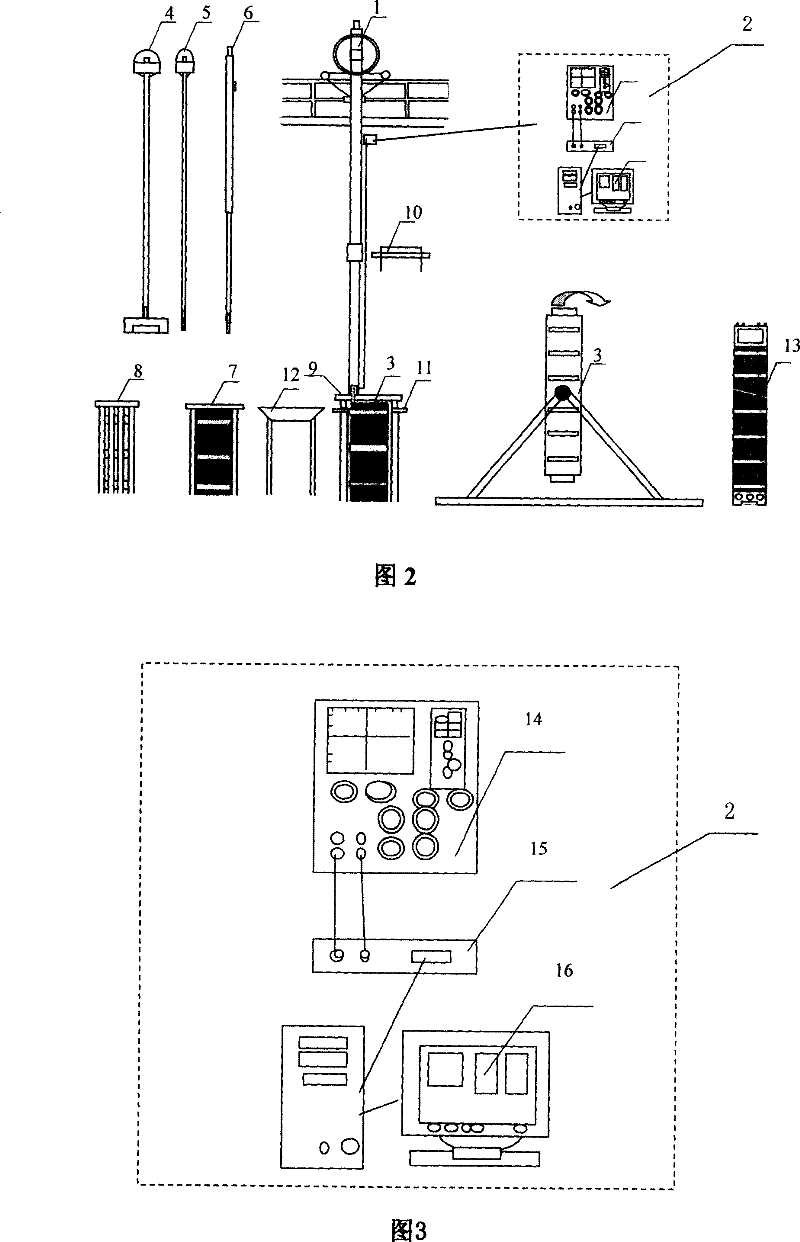

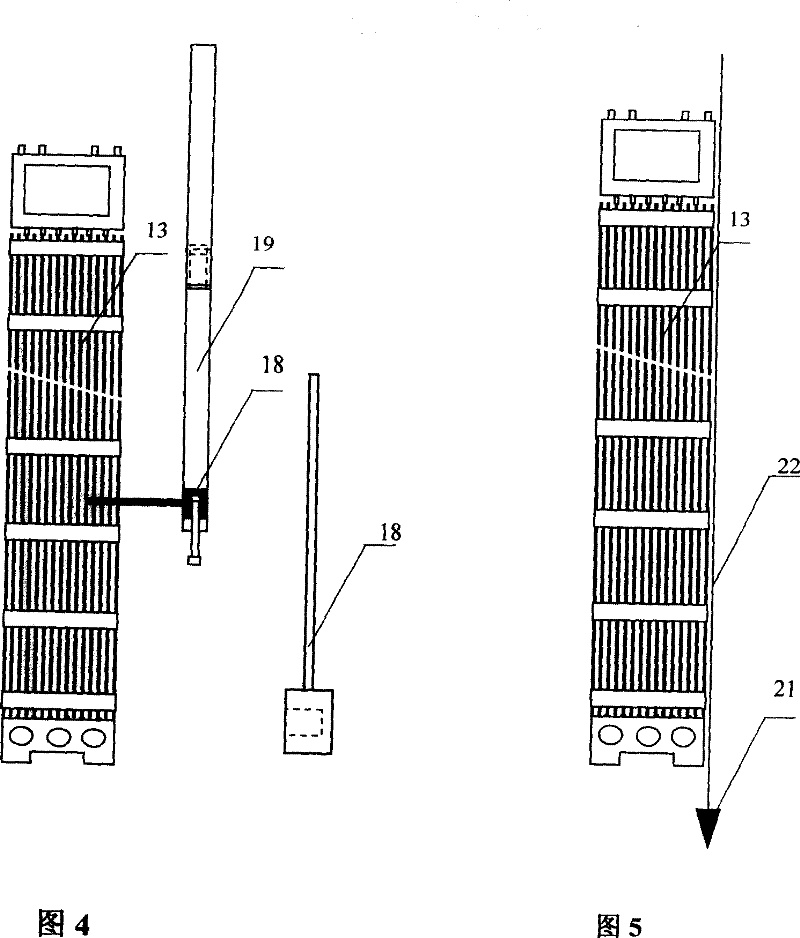

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

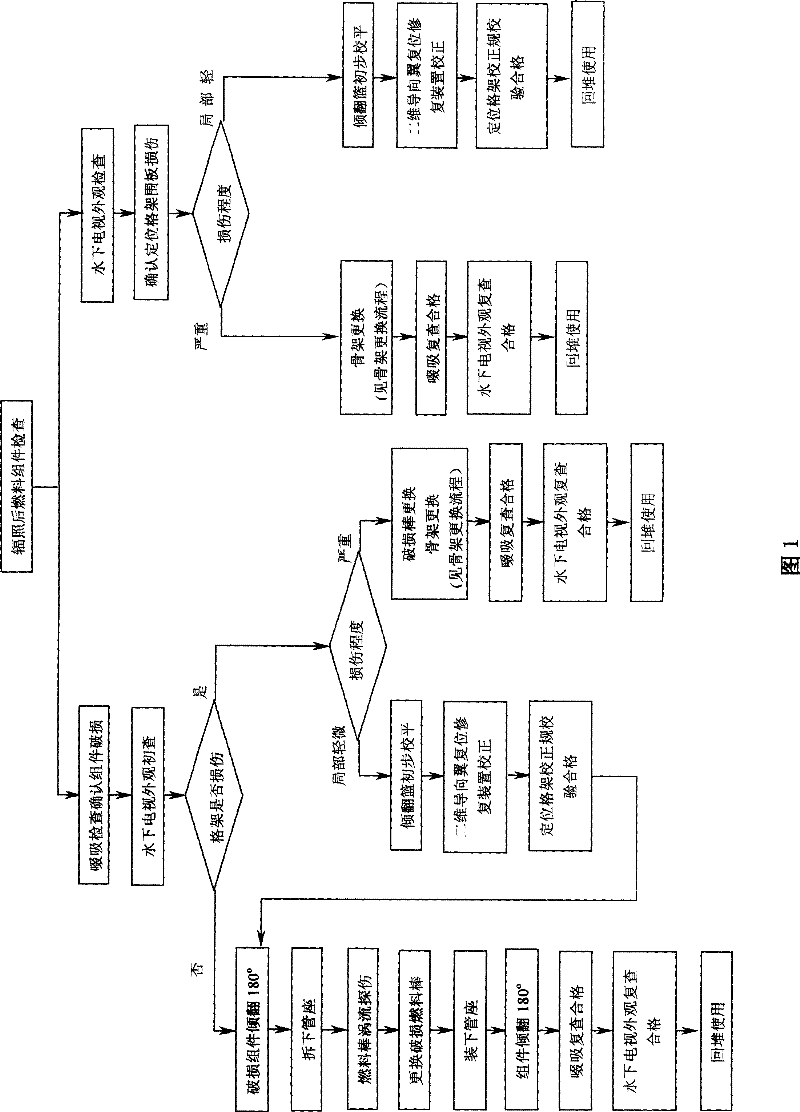

[0040] The flowchart of the damaged fuel assembly repair method after irradiation of the present invention, such as figure 1 As shown, the process flow is:

[0041] (1) Fuel assemblies whose fuel rods are confirmed to be damaged by sipping inspection, and fuel assemblies whose spacer grid coamings are confirmed to be damaged by underwater TV visual inspection;

[0042] (2) When the fuel rod is damaged and the spacer grid coaming is not damaged, turn the damaged component to be repaired 180°, remove the lower pipe seat, conduct eddy current inspection of the fuel rod, replace the damaged fuel rod, and assemble the lower pipe seat, Turn the repaired fuel assembly over 180°, conduct re-inspection of sipping and underwater TV appearance, and return to stacking for use after passing the inspection;

[0043] (3) When the fuel rods are damaged and the dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com