Improved press rolls of paper machine

A press roll and paper machine technology, applied in the direction of paper machine, paper making, press parts, etc., can solve the problems of broken or loose roll body 4, not too high line pressure, uneven internal materials, etc., to improve product quality, withstand The effect of high line pressure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

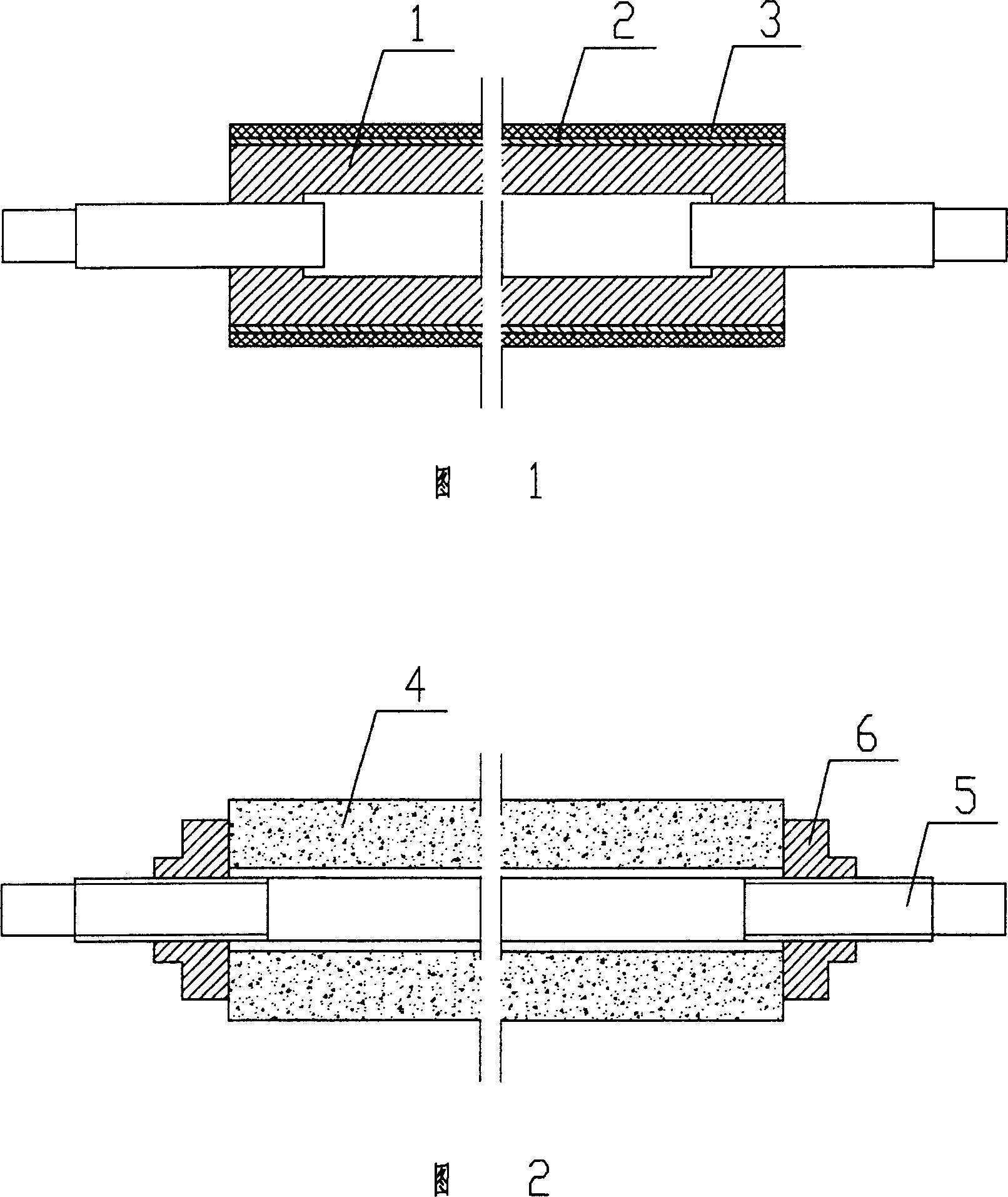

[0011] As shown in Figure 1, the improved paper machine press roll includes a metal roll body 1, the outer peripheral surface of the metal roll body 1 is coated with a stainless steel material layer 2, and the outer layer of the stainless steel material layer 2 is coated with Ceramic layer 3.

[0012] The metal roll body 1 is a cast iron roll body or a steel roll body.

[0013] The ceramic layer 3 is an alumina ceramic powder ceramic layer or a zirconia ceramic powder ceramic layer.

[0014] When making paper, the paper web is in contact with the ceramic layer of the roll body and is separated from the ceramic layer. The 2%-7% fine pores on the surface of the ceramic layer can store some air. The web on the roll surface provides the conditions. The cast iron or steel roller body has high strength, withstands high linear pressure, and is not easy to deform. The bottom layer 2 sprayed on the center roller body 1 adopts a stainless steel layer, which can not only enhance the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com