Automobile exhaust system mounting hanger

A technology of automobile exhaust system and hanging block, which is applied in the directions of power unit, vehicle parts, transportation and packaging, etc., can solve the problems affecting the performance and safety of the whole vehicle, affecting the shock absorption performance of the hanging block, and the fatigue damage of the rubber hanging block, etc. Achieve the effect of improving the service life, compact structure, and good resistance to fatigue damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

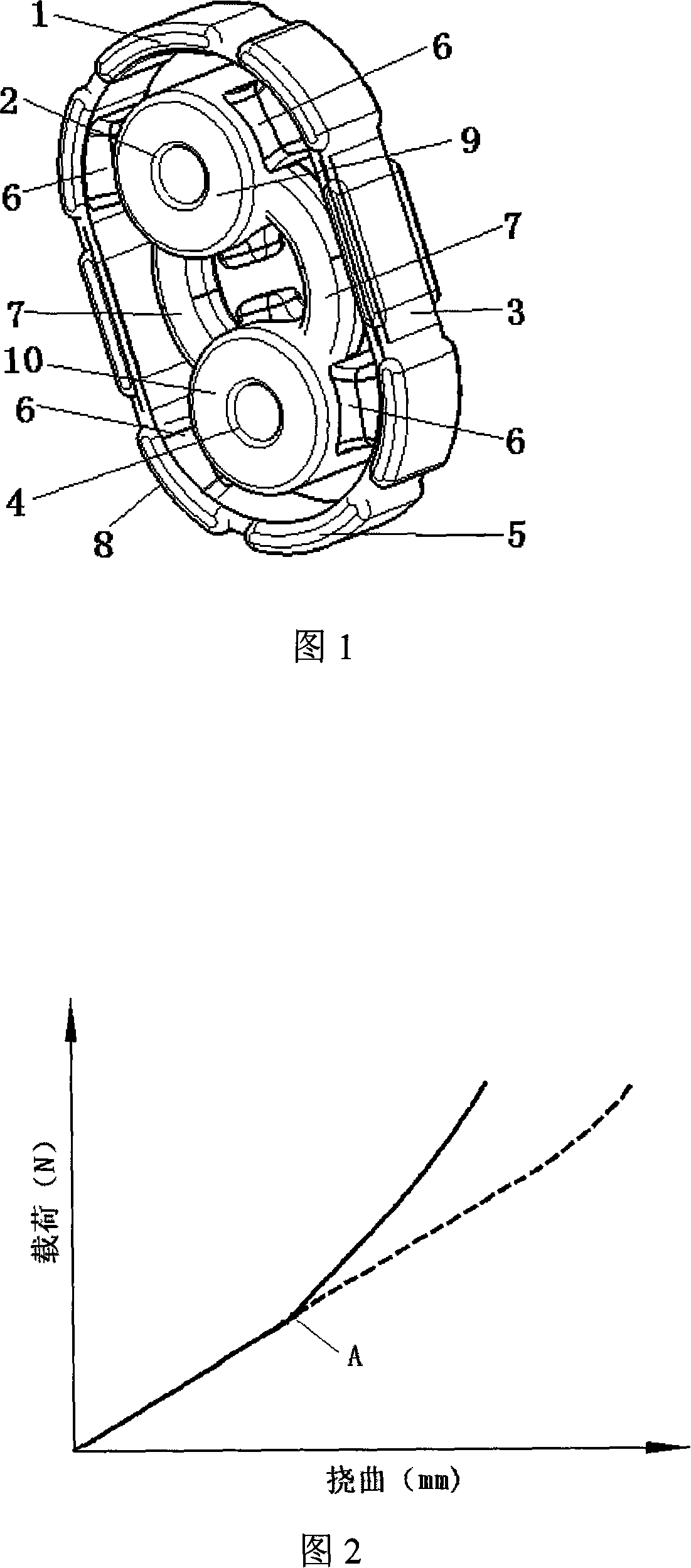

[0026] The installation scheme of the vehicle body and the exhaust pipe on the suspension block 8 proposed by the present invention is: because the exhaust pipe hook and the vehicle body hook part for fixing the exhaust pipe are cylindrical, the described vehicle body The installation part 10 is provided with a car body joint hole 4, and the hook on the automobile body is packed into the car body joint hole 4; the exhaust pipe installation part 9 is provided with an exhaust pipe joint hole 2, and the exhaust pipe of the automobile exhaust system Install the pipe hook into the exhaust pipe joint hole 2. In this way, the relative position of the bodywork and the exhaust pipe will not change due to vibrations.

Embodiment 2

[0028] Example for limiting excessive vibration amplitude: on the surface of the metal frame 3, there are shock-absorbing rubber pads 1, 5 made of rubber materials, and the shock-absorbing rubber pads 1, 5 are wrapped around the metal frame 3. On the surface, it is integrated with the metal frame 3. This connection generally adopts integral molding or bonding.

[0029] The hanging block 8 of the rubber material provided by the present invention allows the elastic coefficient of the rubber material to be small, but under flat road conditions, the vehicle body mounting part 10 connected to the vehicle body and the shock-absorbing rubber pad 5 and the exhaust gas connected to the exhaust system The pipe installation part 9 does not contact the shock-absorbing rubber pad 1, which can fully absorb the vibration of the exhaust system and meet the NVH performance and comfort requirements. When running into poor road conditions, the vehicle body installation part 10 connected with th...

Embodiment 3

[0031] Embodiment of the shape of the vehicle body mounting part 10 and the exhaust pipe mounting part 9: the vehicle body mounting part 10 and the exhaust pipe mounting part 9 are cylindrical, and the axes of the two cylinders are parallel; The axis of the hole 4 coincides with the axis of the vehicle body mounting portion 10 ; the axis of the exhaust pipe coupling hole 2 coincides with the axis of the exhaust pipe mounting portion 9 . The car body mounting part 10 and the exhaust pipe mounting part 9 adopt a cylindrical shape, and the holes are located at the axial position, which is convenient for processing and difficult to damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com