Optical disk apparatus

An optical disc device and optical disc technology, applied in packaging, head configuration/installation, optical recording/reproduction, etc., can solve problems such as the gap between the objective lens and the turntable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the present invention is applied to an optical disc device for recording and reproducing next-generation DVDs and CDs.

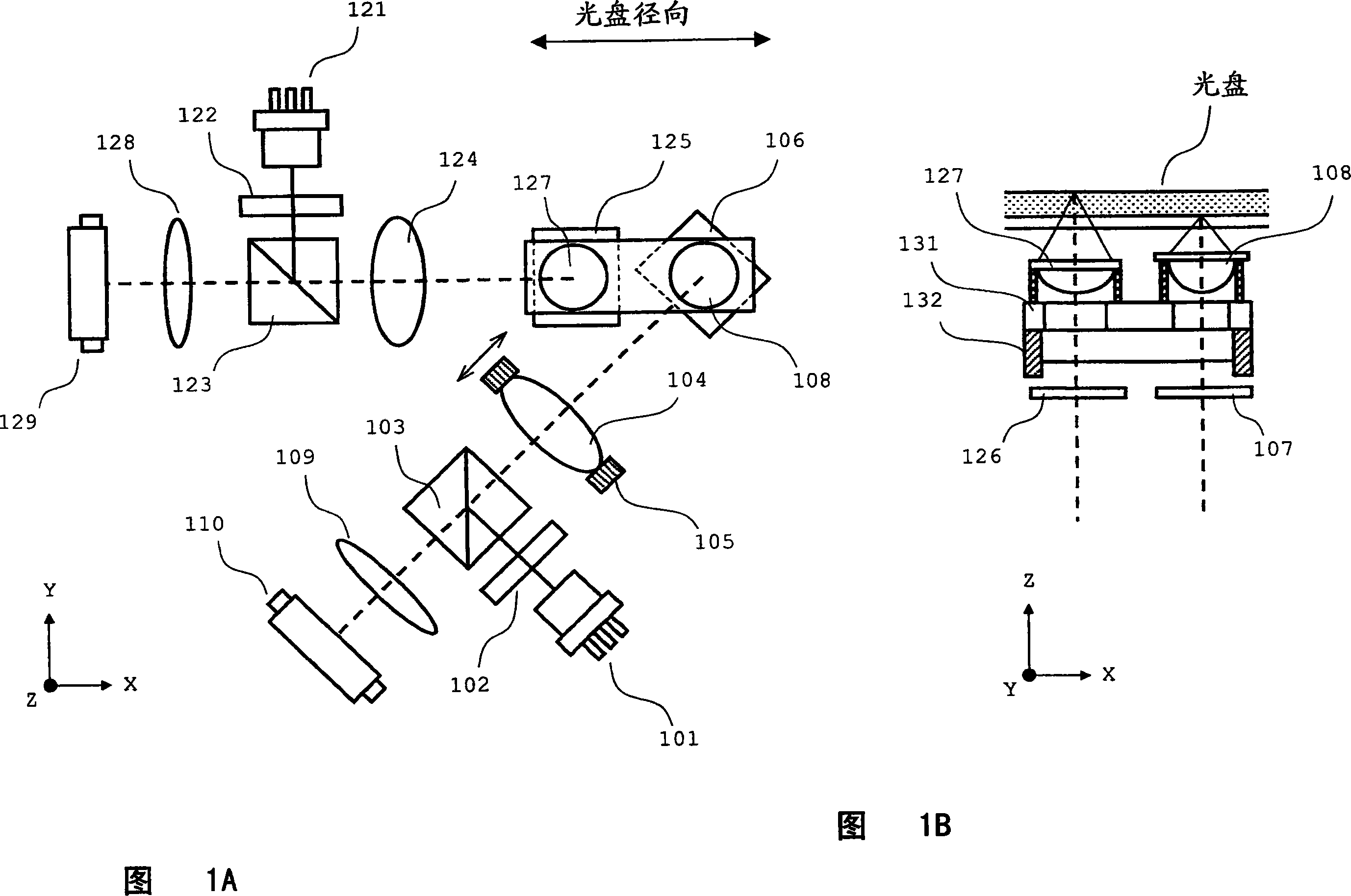

[0039]1A and B show the optical system of the optical pickup of the embodiment. FIG. 1A is a plan view of an optical system, and FIG. 1B is a side view of a peripheral portion of an objective lens actuator. This optical system is classified into an optical system for next-generation DVDs and an optical system for CDs.

[0040] The optical system for the next-generation DVD consists of a semiconductor laser 101, a diffraction grating 102, a polarizing beam splitter 103, a collimator lens 104, a lens actuator 105, a rising mirror (rising mirror) 106, a λ / 4 plate 107, a first An objective lens 108, an anamorphic lens (anamorphic lens) 109, and a photodetector 110 are constituted.

[0041] The semiconductor laser 101 outputs blue laser light with a wavelength of about 400 nm. The diffraction grating 102 divides the laser light emitt...

Embodiment 2

[0081] In this embodiment, the present invention is applied to an optical disc device for recording and reproducing next-generation DVDs, DVDs, and CDs.

[0082] The optical system of the optical pickup of the embodiment is shown in FIGS. 8A and 8B. FIG. 8A is a plan view of the optical system, and FIG. 8B is a side view of the peripheral portion of the objective lens actuator. The optical system is classified into an optical system for next-generation DVD and an optical system for CD / DVD.

[0083] The optical system for CD / DVD is composed of a diffraction grating 122 , a polarizing beam splitter 123 , a collimator lens 124 , a rising mirror 125 , an anamorphic lens 128 , a photodetector 129 , a semiconductor laser 144 , and a second objective lens 145 . Here, the semiconductor laser 144 emits laser light of an infrared wavelength with a wavelength of about 780 nm and laser light of a red wavelength with a wavelength of about 650 nm. The second objective lens 145 condenses t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com