Seal structure

A sealing structure and structure technology, which is applied to the sealing of engines, electrical equipment structural parts, electrical equipment shells/cabinets/drawers, etc., can solve problems such as inability to eliminate gap c, insufficient countermeasures, etc., and achieve the goal of suppressing the formation of gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] Next, embodiments of the present invention will be described with reference to the drawings.

no. 1 example …

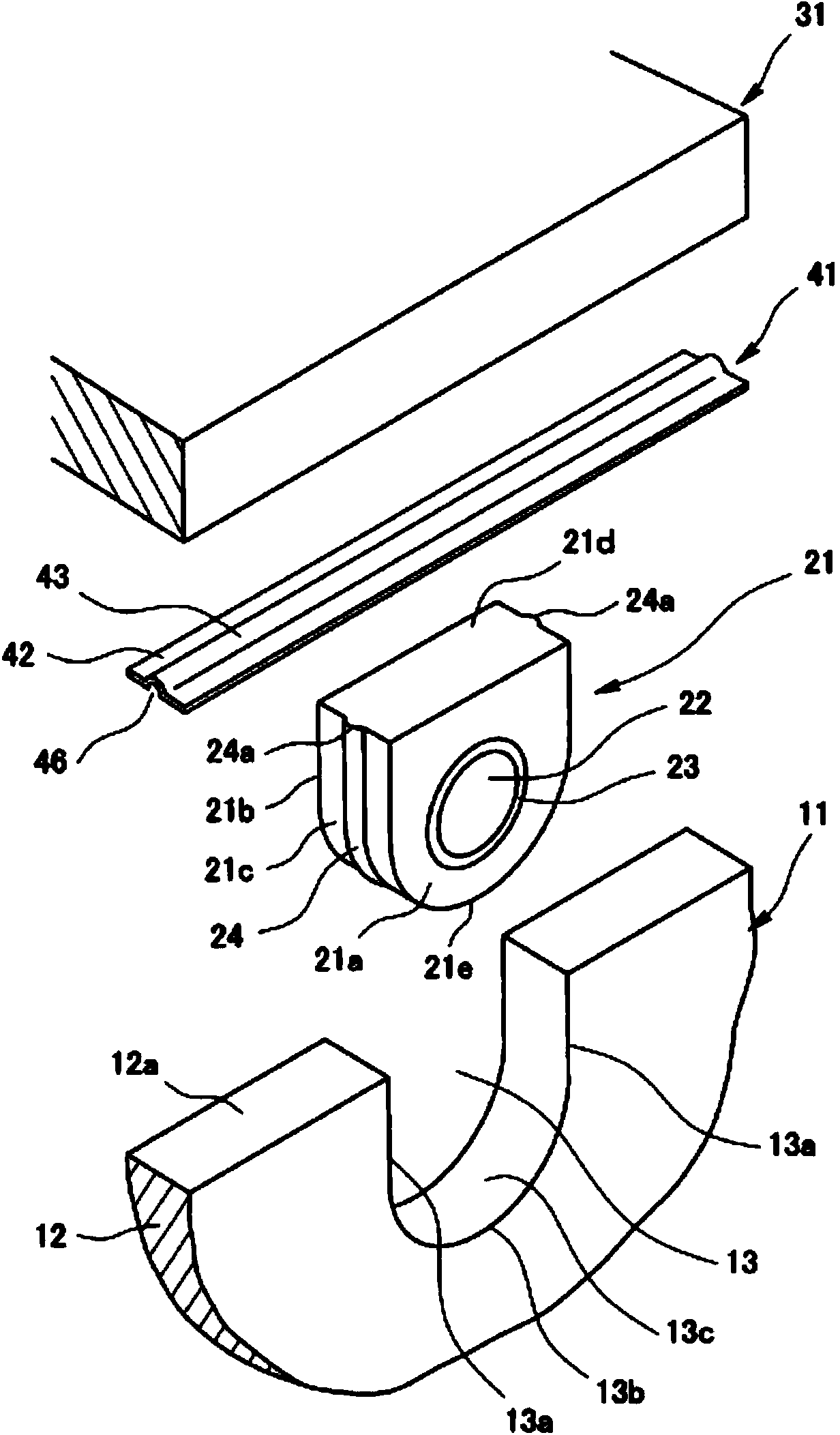

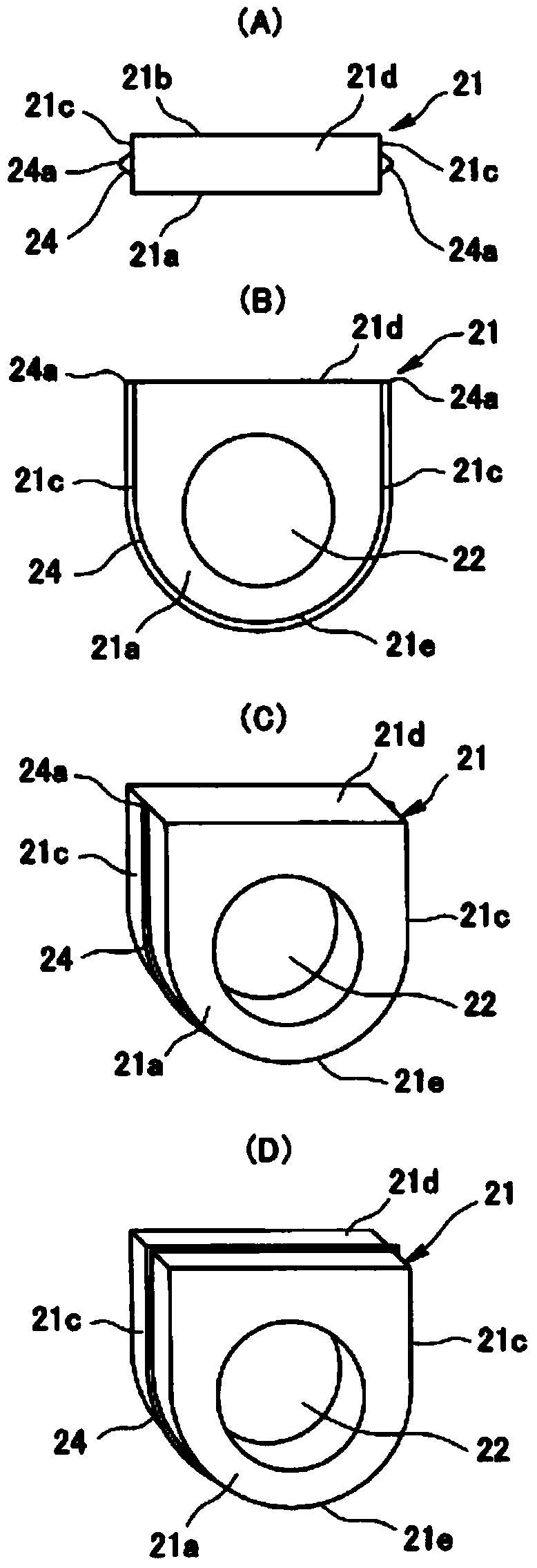

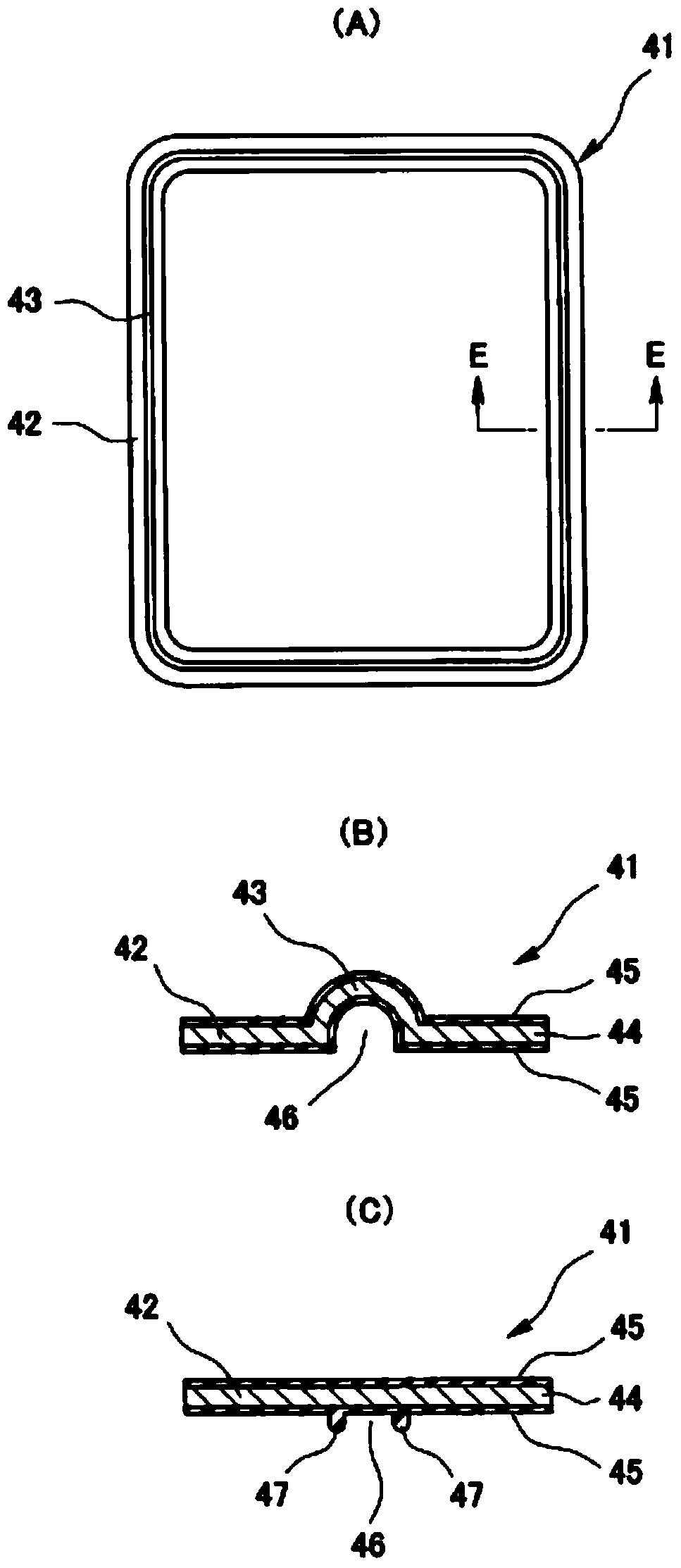

[0130] figure 1 The state before assembly of the sealing structure according to the first embodiment of the present invention is shown, and the frame body 11 , the grommet 21 , the cover 31 , and the metal substrate gasket 41 are drawn respectively. figure 2 (A) (B) (C) is the single figure of the retaining ring 21, image 3 (A) and (B) are a single view of the metal substrate gasket 41, Figure 4 (A) (B) and Figure 5 It is an explanatory diagram of the sealing structure. The sealing structure according to this embodiment is used to seal three-sided junctions in electrical equipment, engines, and the like, and is called a three-sided seal in terms of its function.

[0131]The frame body 11 is formed by a rigid material such as a predetermined metal or hard resin, and is provided with a vertical planar wall portion 12 as an upright portion on the side of the frame body. It is arranged in a way to penetrate the thickness direction of the wall. The grommet mounting portio...

no. 2 example …

[0149] Figure 7 The state before assembly of the sealing structure according to the second embodiment of the present invention is shown, and the frame body 11 , the grommet 21 , the cover 31 , and the metal substrate gasket 141 are drawn respectively. Figure 8 (A) (B) (C) is the single figure of the retaining ring 21, Figure 9 (A) (B) (C) is a single view of the metal substrate liner 141, Figure 10 (A) (B) and Figure 11 (A) is an explanatory diagram of the sealing structure. The sealing structure according to this embodiment is used to seal three-sided junctions in electrical equipment, engines, and the like, and is called a three-sided seal in terms of its function.

[0150]The frame body 11 is formed by a rigid material such as a predetermined metal or hard resin, and is provided with a vertical planar wall portion 12 as an upright portion on the side of the frame body. It is arranged in a way to penetrate the thickness direction of the wall. The grommet attachment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com