Technique and device for catalyzing biomass fast thermal cracking by high temperature ironic liquid

A technology of ionic liquid and pyrolysis, which is applied in the field of high-temperature ionic liquid catalyzed rapid pyrolysis of biomass and equipment, to achieve rapid pyrolysis process, low investment cost and stable temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

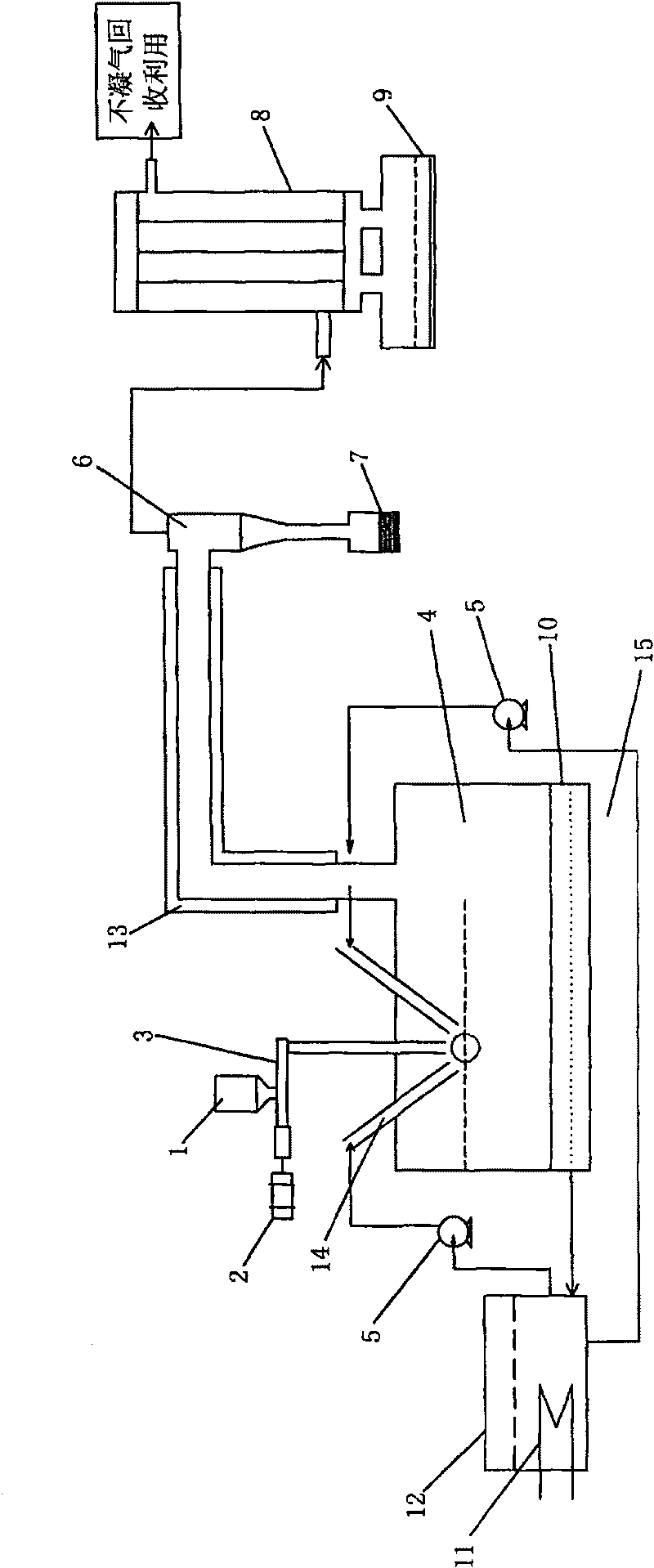

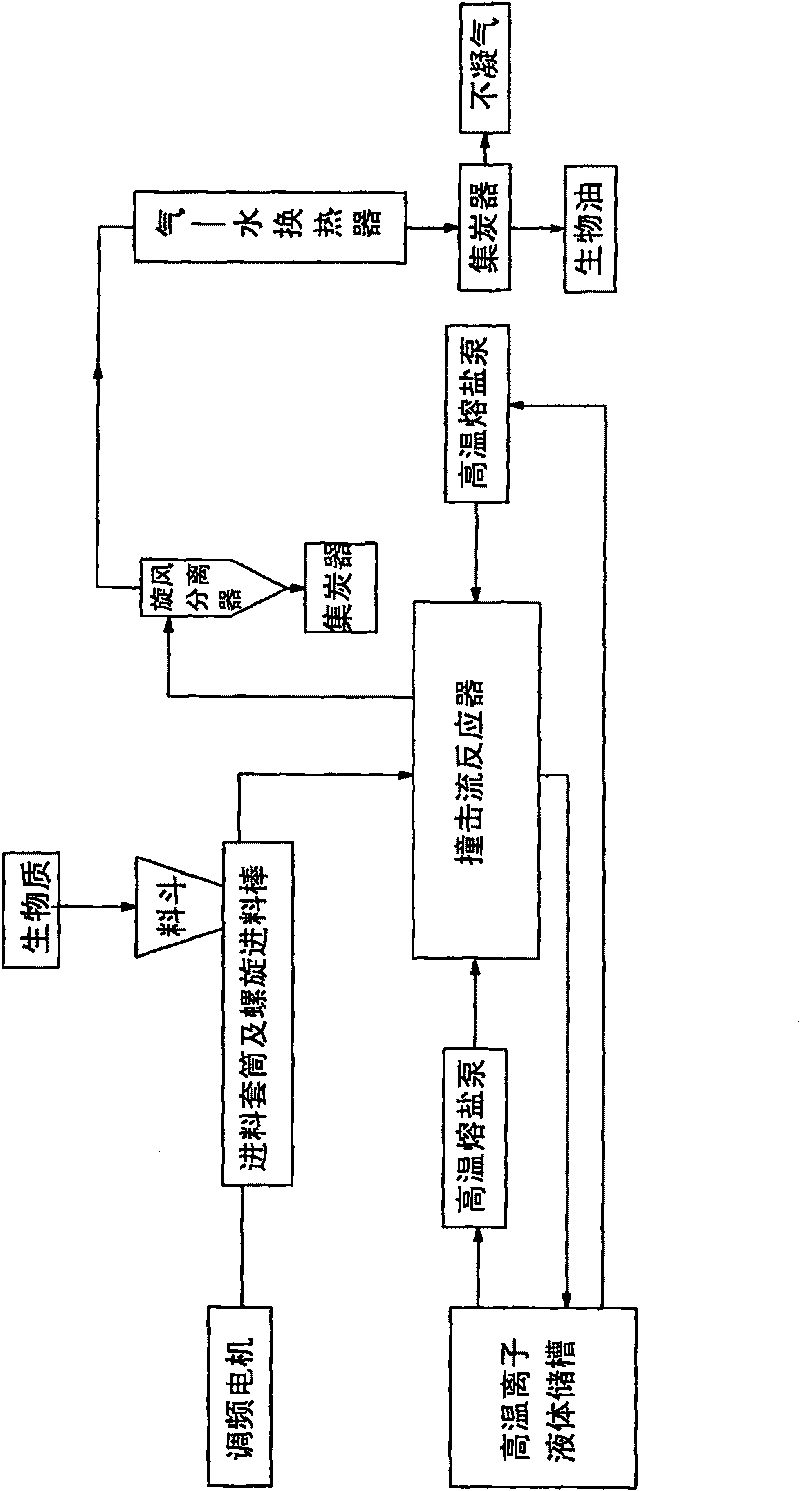

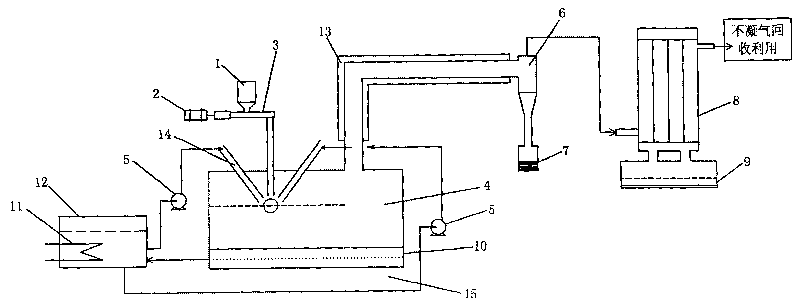

Method used

Image

Examples

Embodiment 1

[0025] 300g of molten salt NaNO 3 Place in a 500ml three-neck round bottom flask, heat with an external electric heating mantle, and constantly fill the inside of the round bottom flask with N 2 , connect two condenser tubes in series at the upper end of the round bottom flask, and use water close to 0°C to condense, and connect a 125ml round bottom flask at the lower end of the condenser tube. When the heating temperature in the round bottom flask rises to 307°C, NaNO 3 It starts to melt and becomes liquid. When the temperature in the round-bottomed flask rises to 335°C, continuously and evenly add 100 g of sawdust with a particle diameter of about 1.5 mm into the round-bottomed flask through a modified grinding port of the round-bottomed flask. When the sawdust particles are in contact with the high-temperature molten salt, the sawdust particles are cracked within less than 1 second, and oil droplets are enriched on the tube wall of the condenser tube, which will finally be...

Embodiment 2

[0027] Molten salt KNO 3 、NaNO 2 and NaNO 3 Be 53%: 40%: 7% according to mass ratio and be mixed with mixed molten salt, the mixed molten salt of 300g is placed in the three-neck round-bottomed flask of 500ml, external electric heating mantle heating, constantly fill into N to the inside of round-bottomed flask. 2 , connect two condenser tubes in series at the upper end of the round bottom flask, and use water close to 0°C to condense, and connect a 125ml round bottom flask at the lower end of the condenser tube. When the heating temperature in the round-bottom flask rises to 142°C, the mixed molten salt begins to melt and assumes a liquid state. Continuously and uniformly add 100g of wood chips with a particle diameter of about 1.5mm into the bottom flask. After the wood chips contact with the high-temperature molten salt, the wood chips will be cracked within <1s, and then enriched on the wall of the condenser tube. There were oily drops which eventually collected in a 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com