Plasma display device

A plasma display and discharge unit technology, applied to solid cathode parts, cold cathode tubes, etc., can solve problems such as hindering the improvement of xenon gas efficiency and scattered wall charge distribution, and achieve the effect of improving jitter characteristics and improving discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

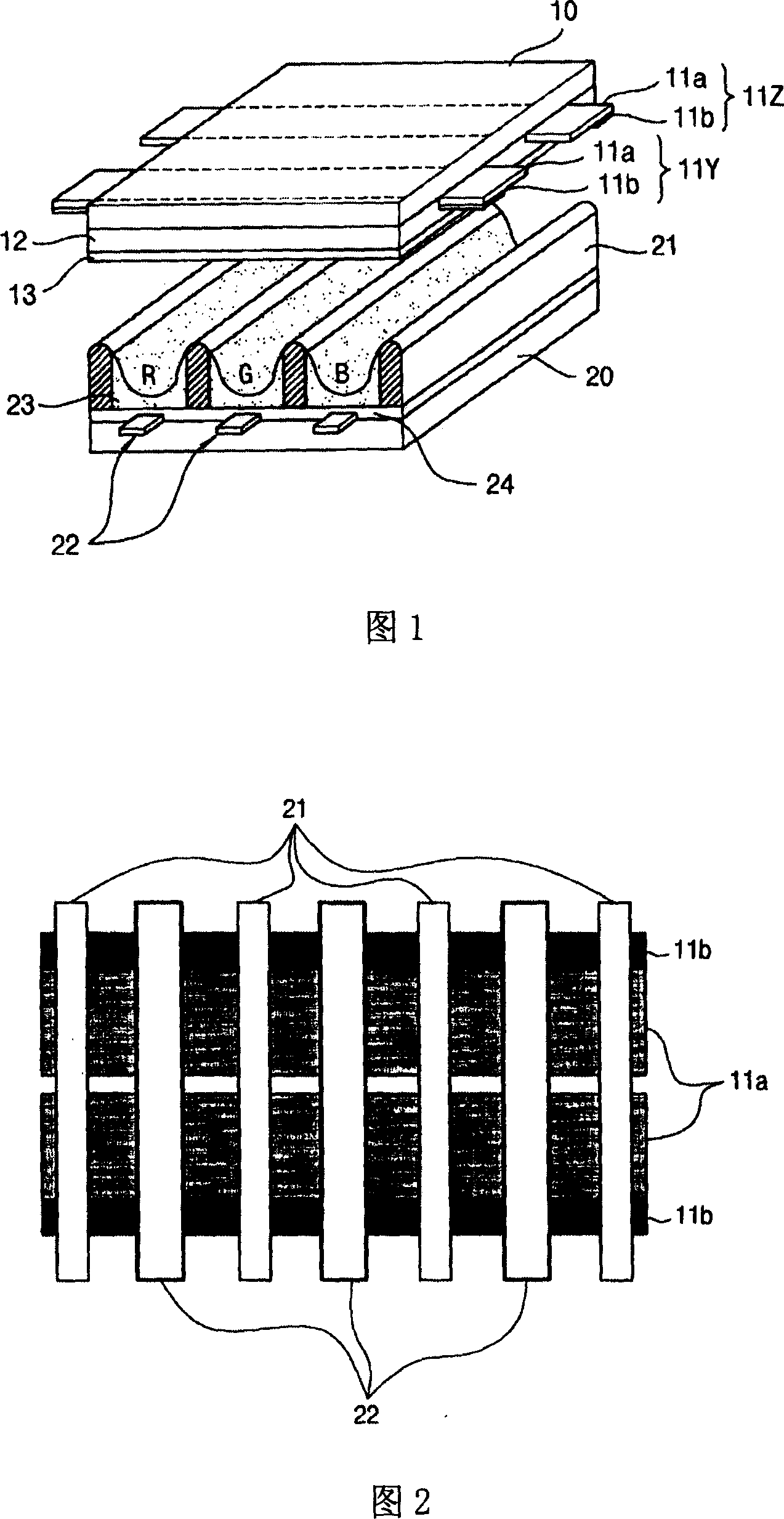

[0045] In order to further illustrate the above-mentioned purpose, structural features and effects of the present invention, the PDP of the present invention will be described in detail below with reference to the accompanying drawings.

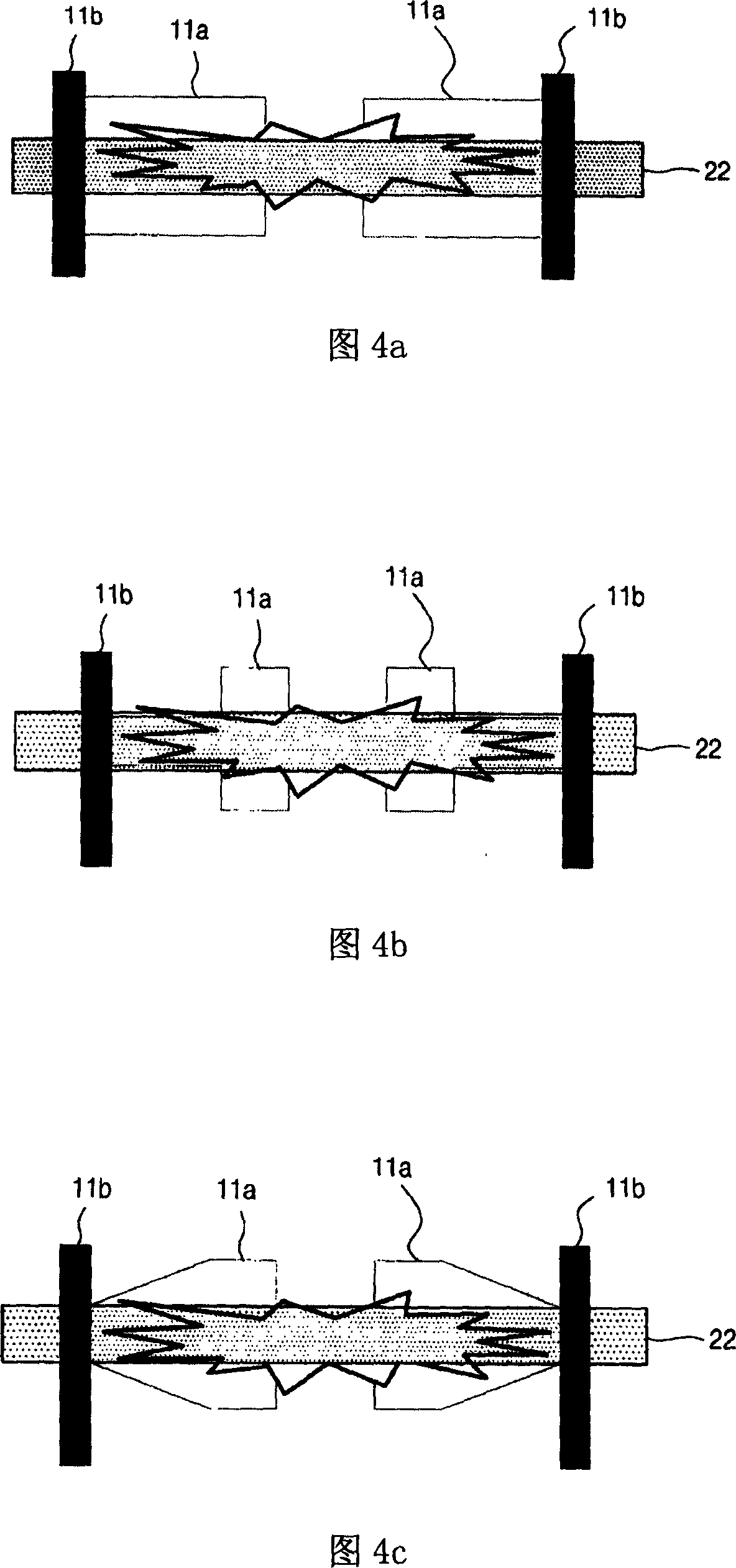

[0046] 7a to 7c are schematic diagrams of electrode structures in the discharge cells of the plasma display of the present invention.

[0047] First, in the electrode structure shown in 7a, the transparent electrode 11a is arranged on the front substrate in a quadrangular structure. The transparent electrodes 11a of such a quadrangular structure are arranged at both ends of the discharge cells where the bus electrodes 11b are located, between two transparent electrodes 11a, and the two transparent electrodes 11a face each other. In addition, the area of the corresponding address electrode 22 inside the discharge cell is wider than the area of the transparent electrode 11a, and the vertical width of the address electrode 22 in the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com