Entry conveyor and pan section for the same

A technology for chute joints and conveyors, which is applied in the field of tunnel conveyors and chute joints for tunnel conveyors, which can solve the problems of high chain load, high proportion of scraper chain wear, high chain force, etc., and achieve wear reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

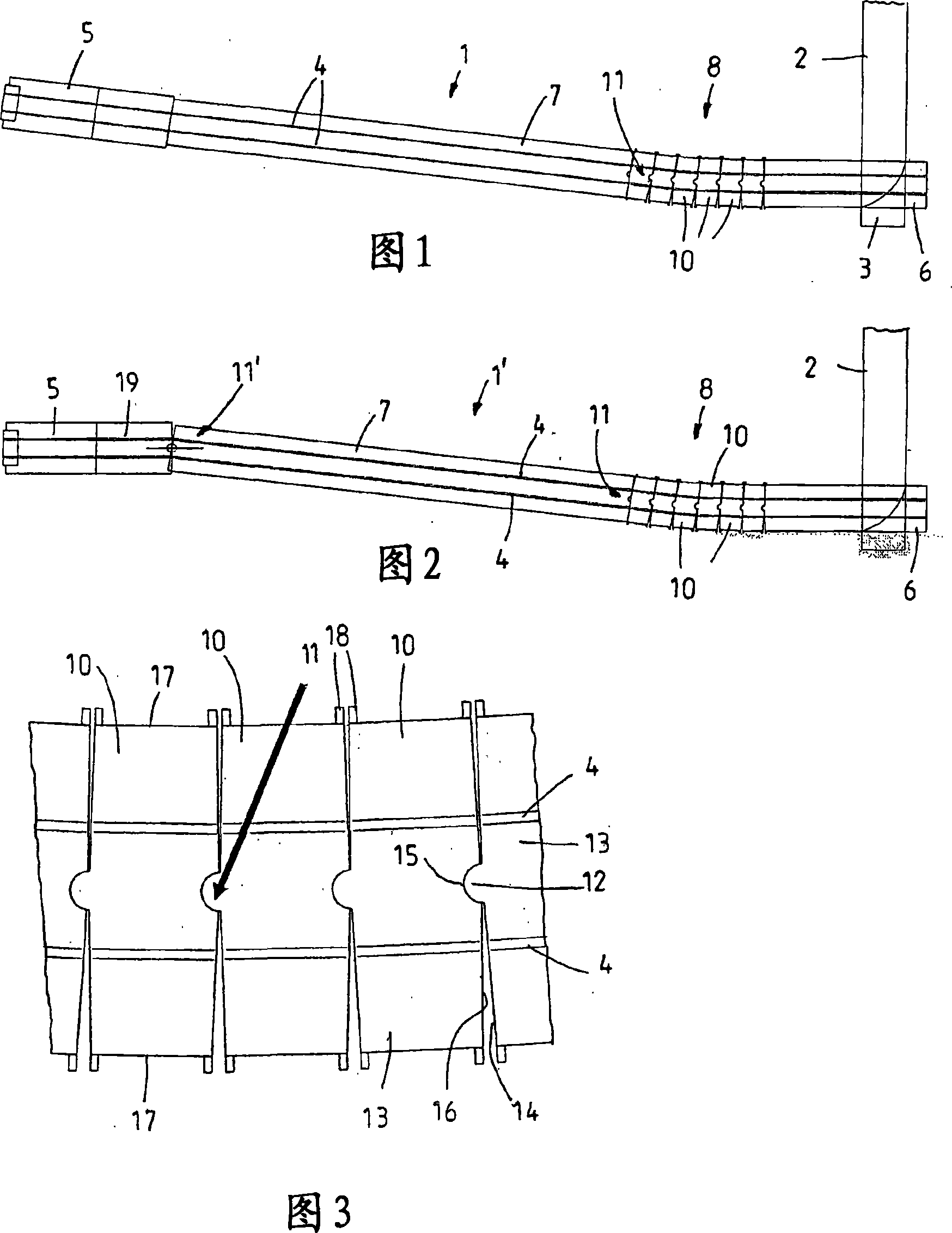

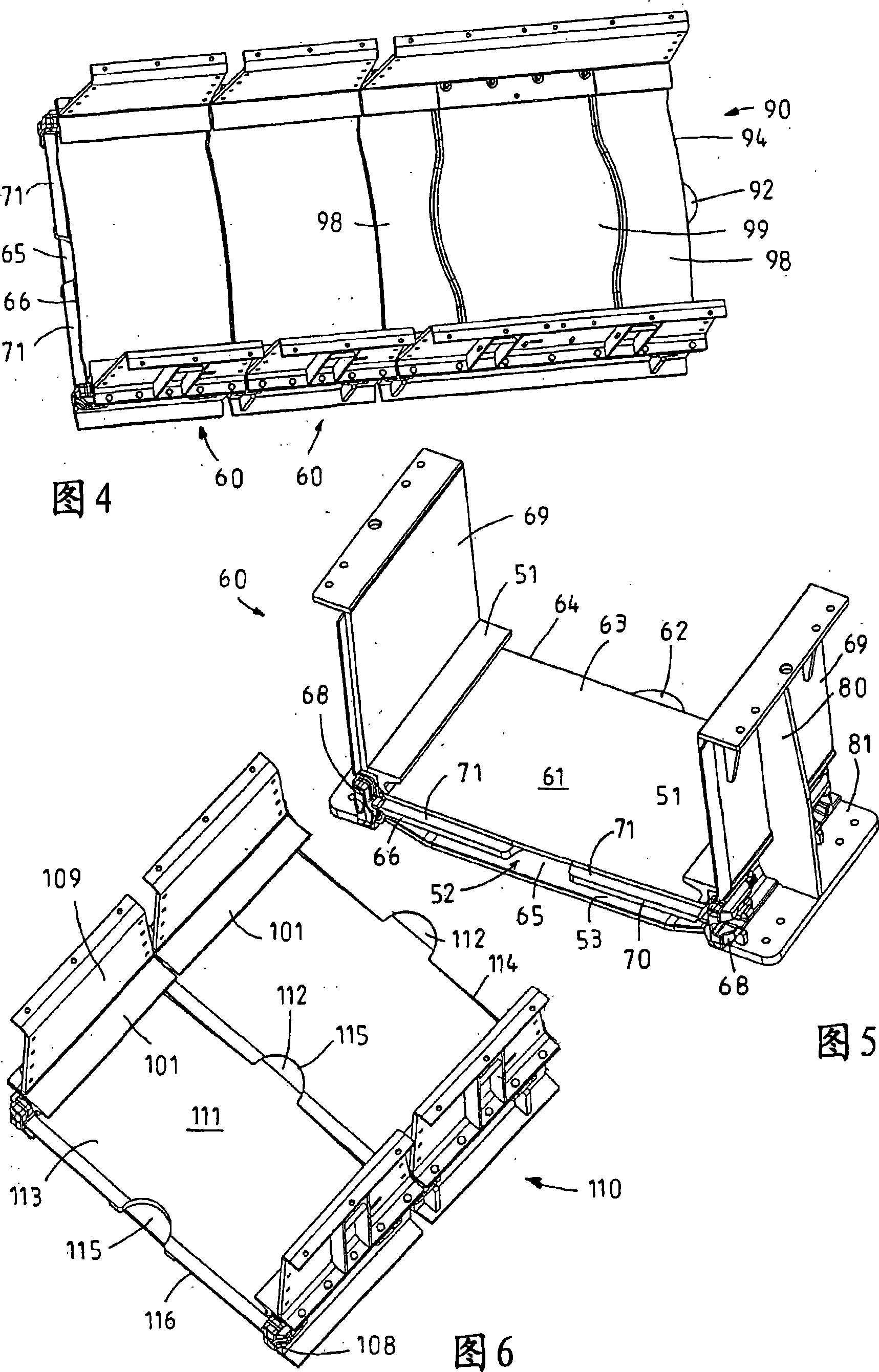

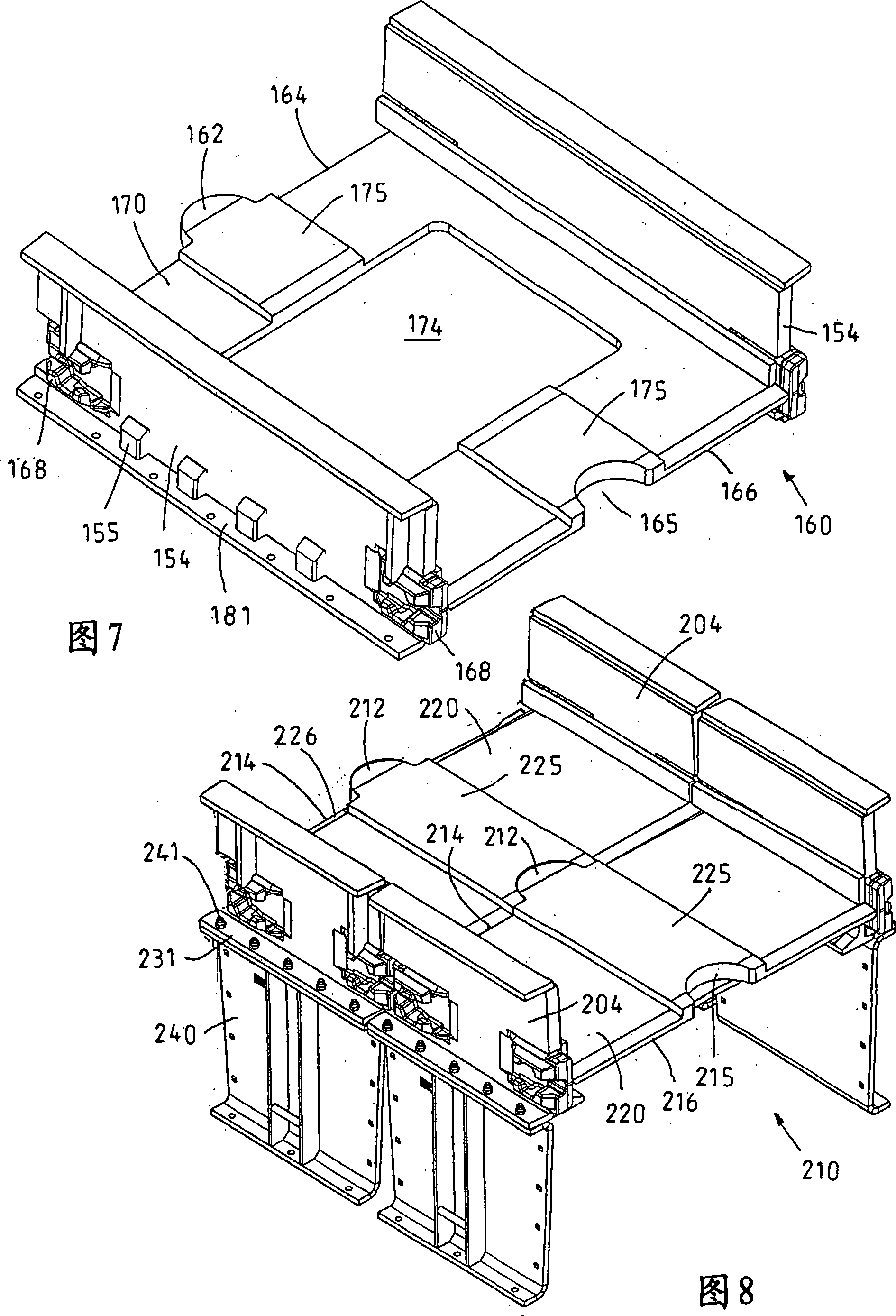

[0027] FIG. 1 shows a greatly schematically simplified approach conveyor 1 designed as a face-entry transfer conveyor, as it can be used in underground mining, in particular in coal mining. The material recovered by the face conveyor on the mining face, not otherwise shown, is thrown onto the entry conveyor 1 on a special trough formed as a cross frame (Kreuzrahmen) 3, where not only the face conveyor 2 Furthermore, the alley conveyors 1 are designed as double-center scraper chain conveyors, including two chain strands 4 of a double-center scraper chain, which are only schematically described here for the alley conveyor 1 . The two shown chain strands 4 of the scraper chain run in the upper branch of the conveying chute 7 from the cross frame to the drive station 5, which consists of a number of identically formed standard chute segments, not shown in detail, As this is known to the skilled person. The two chain strands 4 are deflected at a drive station 5 arranged at one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com