Printed wiring board, method for forming the printed wiring board, and board interconnection structure

A technology for printed circuit boards and interconnection structures, which is applied in the structural connection of printed circuits, printed circuits, and printed circuit manufacturing. It can solve the problems of easy peeling and reduced connection strength, and achieve the goal of enhancing connection strength and preventing peeling strength. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

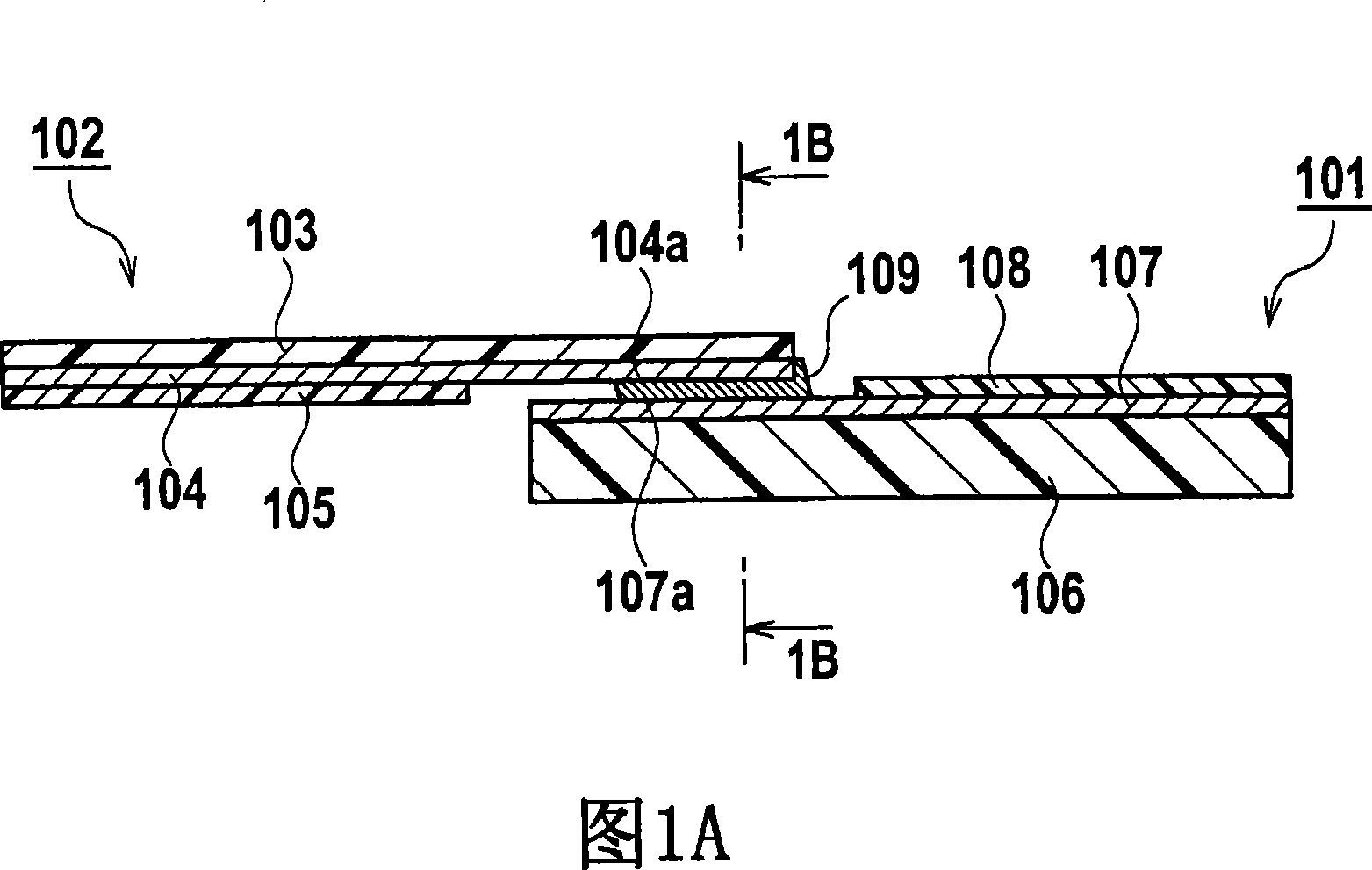

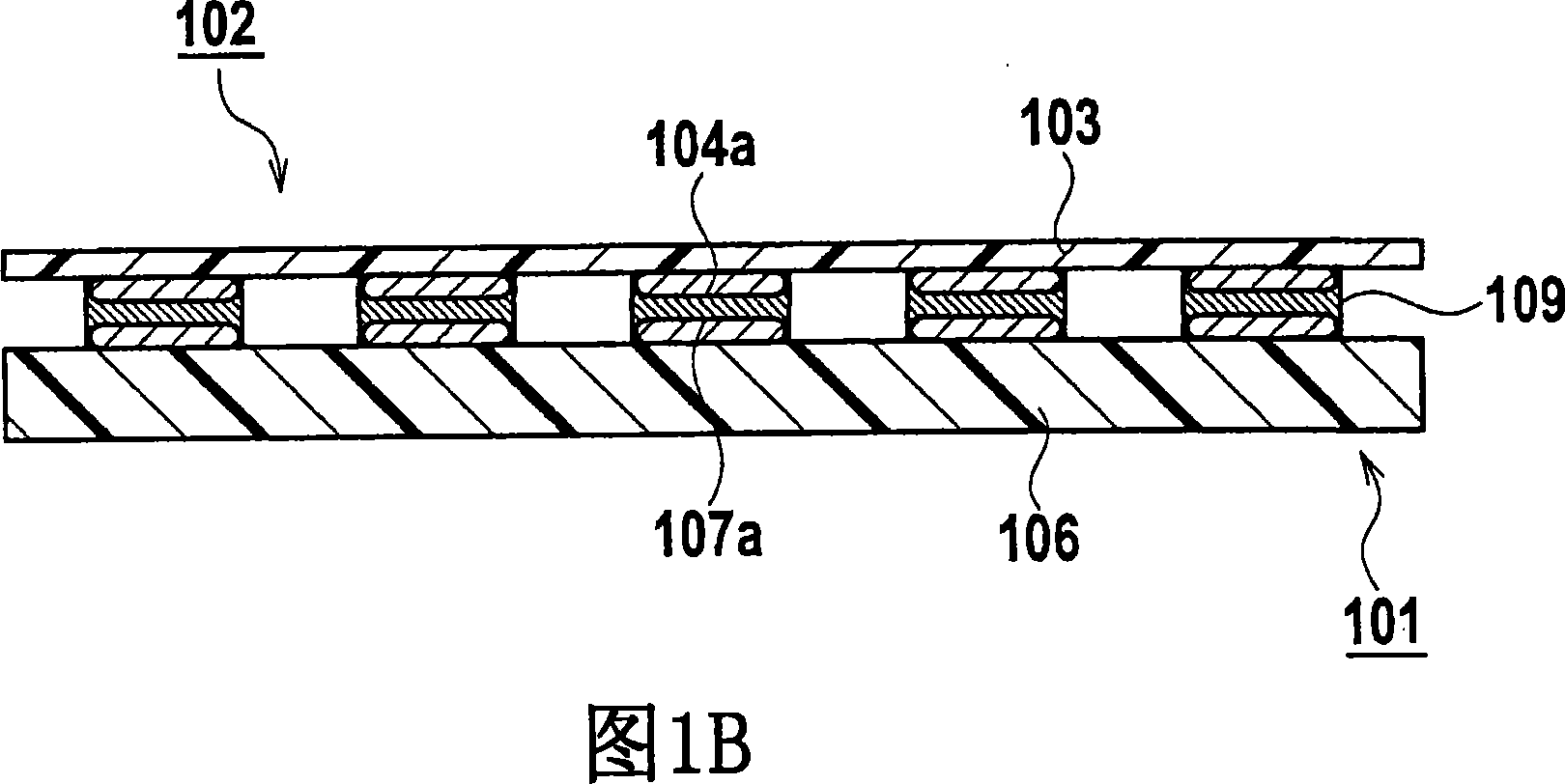

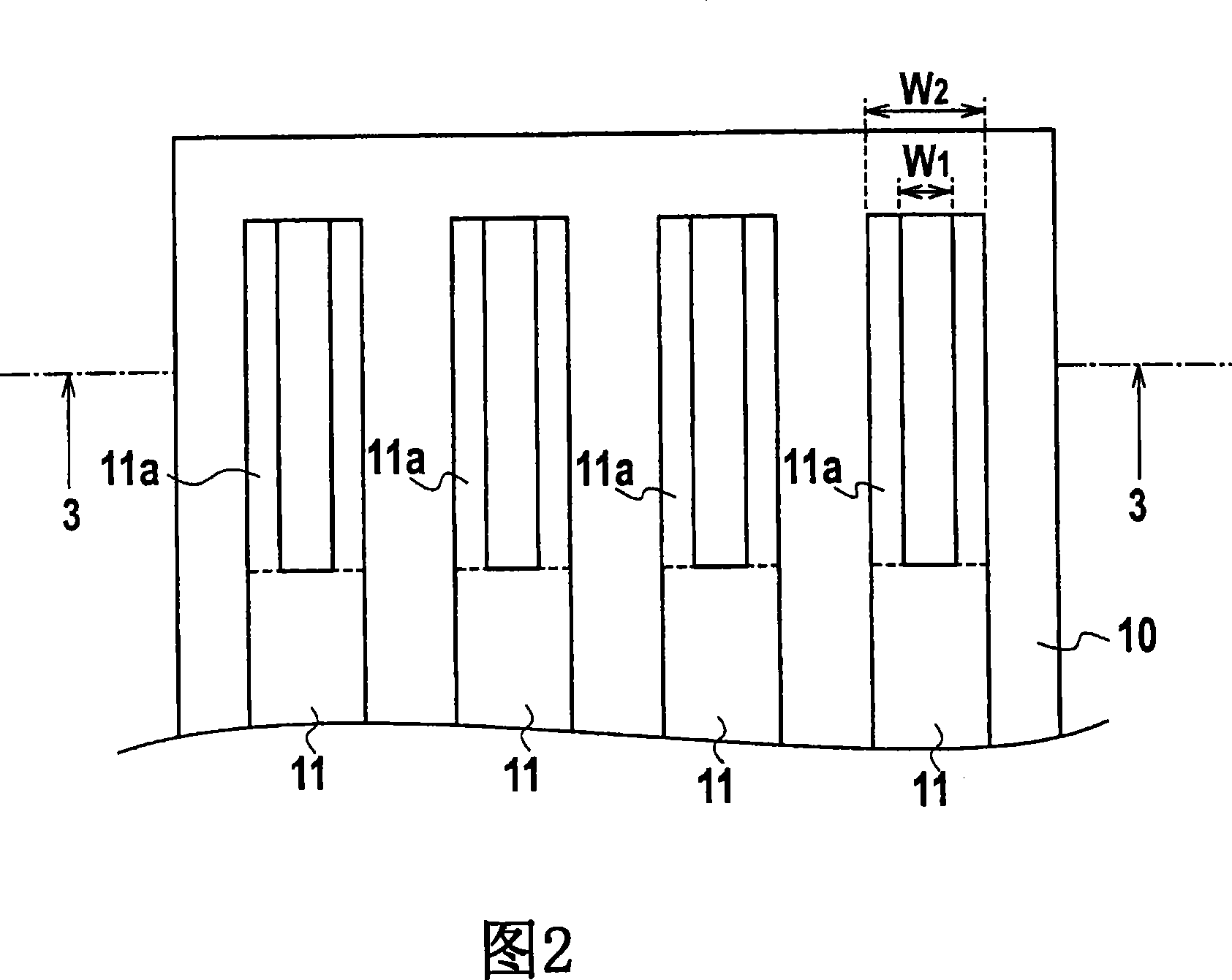

[0034]Non-limiting embodiments of the invention will be described below with reference to the accompanying drawings. In the following description, the same or similar parts of the drawings are identified by the same or similar reference numerals. It is to be noted that the drawings are only schematic, and the relationship between the thickness and planar dimensions, the ratio of the thickness of each layer, and the like are different from the actual ones. Therefore, specific thicknesses and dimensions are determined by referring to the following description. Furthermore, in the drawings, it is inevitable to include portions where the relationship and ratio of dimensions are different from each other.

[0035] (first non-limiting embodiment)

[0036] (printed circuit board)

[0037] As shown in FIG. 2, the printed wiring board according to the first embodiment of the present invention includes an insulating layer 10, a conductive circuit 11 having connection terminals 11a on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com