Noncontact type automatic detection method and device for drum-shaped workpiece shape and position dimension

A technology for automatic detection devices and cylindrical workpieces, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc., can solve the problems of low product qualification rate, reduce scrap rate, improve efficiency, and facilitate use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

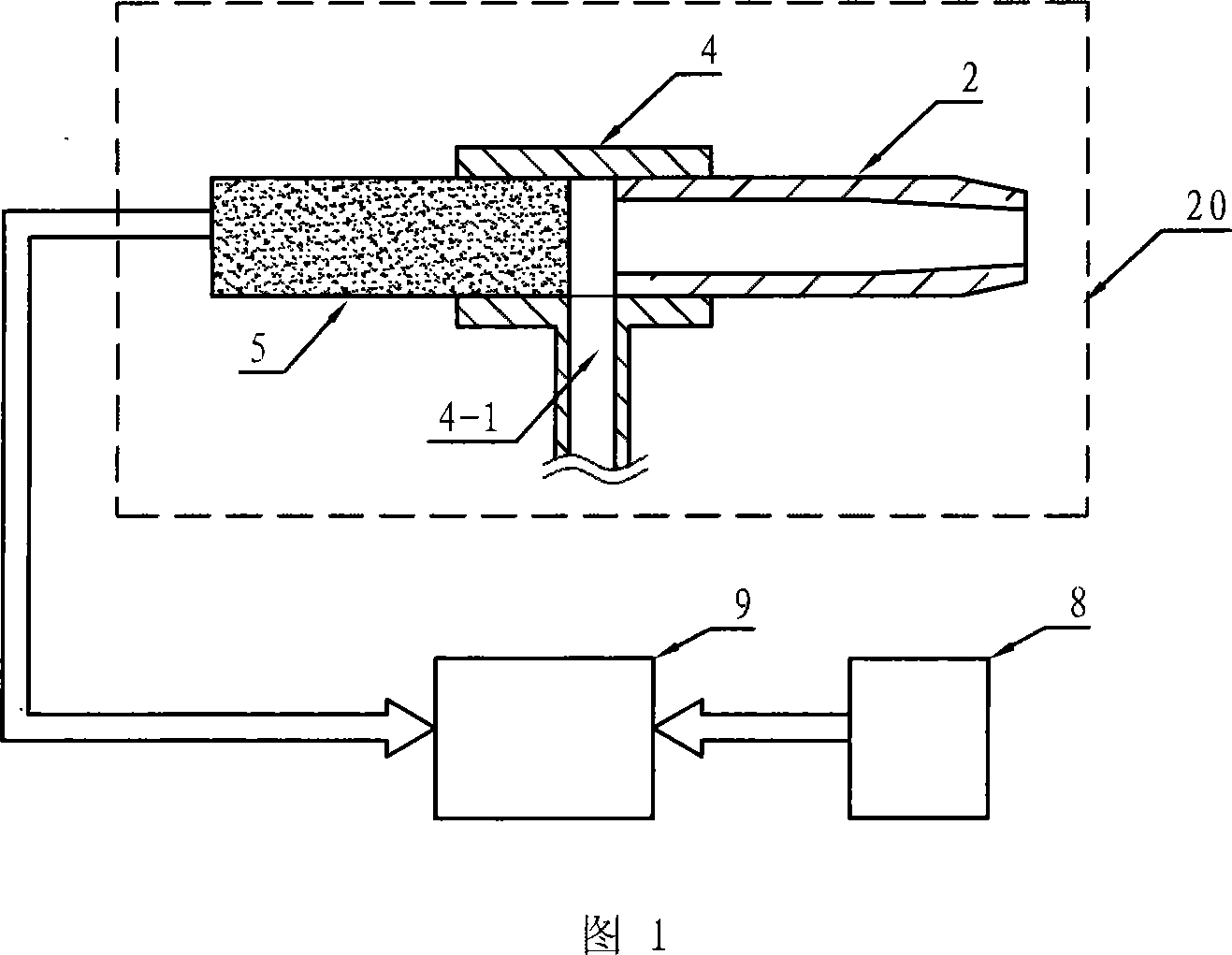

[0017] The automatic detection method of the shape, position and size of the non-contact cylindrical workpiece in this embodiment is as follows:

[0018] Step 1: Determine the reference point of the measurement, and mark the position z of the section to be measured on the outer surface of the workpiece to be measured 1 to z n , and then perform step 2;

[0019] Step 2: Control the measured workpiece to rotate at a constant speed, and at the same time make the encoder rotate synchronously with the measured workpiece, and then perform step 3;

[0020] Step 3: Continuously and evenly spray the ultrasonic coupling agent onto the surface of the workpiece to realize ultrasonic coupling; then perform step 4;

[0021] Step 4: Adjust the position of the ultrasonic probe so that the extension line of the central axis of the ultrasonic probe intersects the central axis of the workpiece to be measured, so that the ultrasonic waves emitted by the ultrasonic probe are incident perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com