The second kind absorption heat pump with two terminal or multiple terminal supplying heat

An absorption heat pump, multi-terminal heating technology, applied in the direction of adsorption machines, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of reduced economic benefits, discounts, unsatisfactory results, etc., to increase waste heat utilization efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

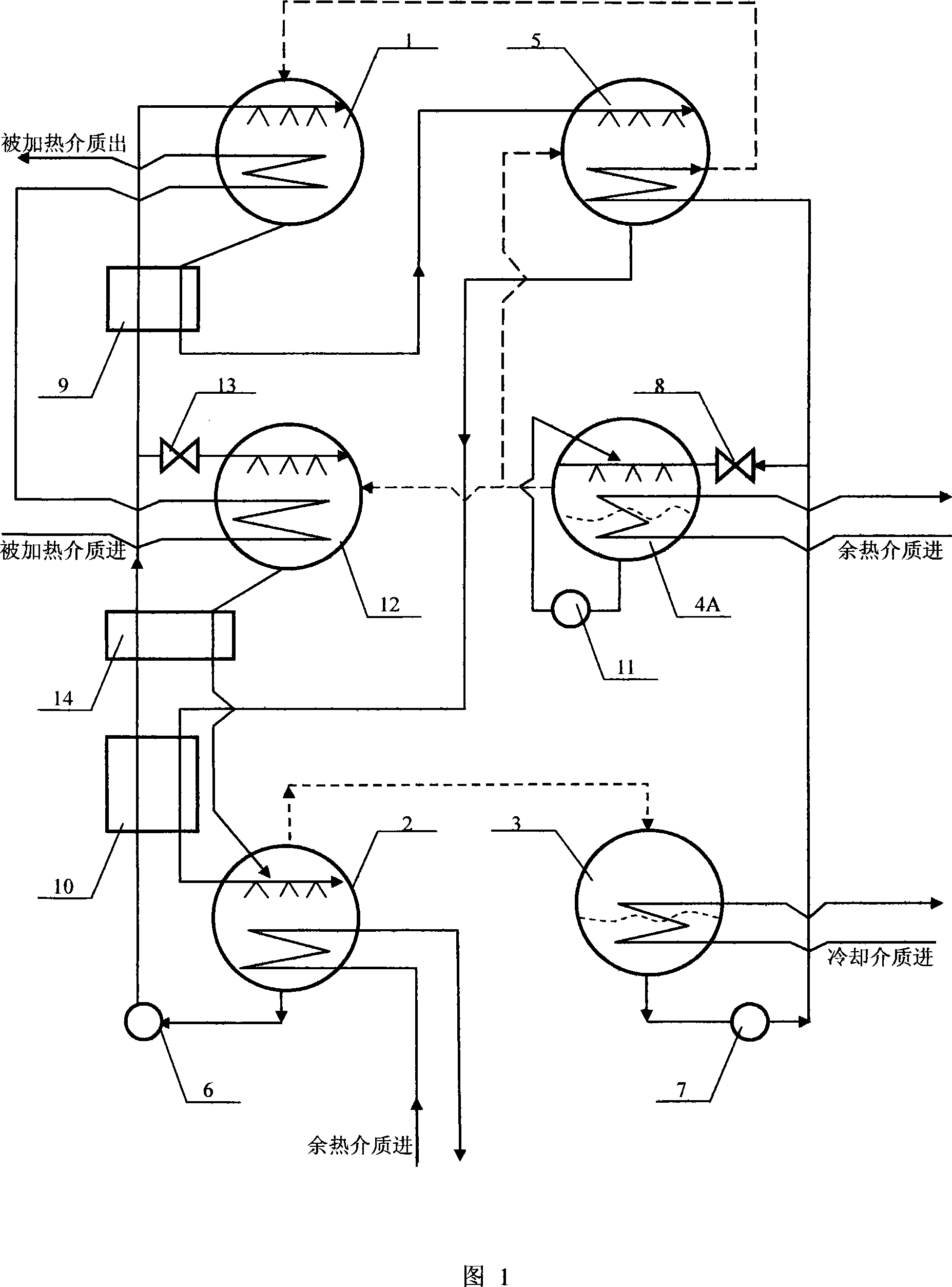

[0030] Taking the closed second type absorption heat pump provided by the present invention with two absorbers providing heat at both ends as an example, as shown in Figure 1, the purpose of the present invention is achieved in this way:

[0031] 1. Structurally, the heat pump is mainly composed of absorber 1, generator 2, condenser 3, evaporator 4A, absorption-evaporator 5, solution pump 6, refrigerant liquid pump 7, throttle valve 8, solution heat exchanger 9 and 10, refrigerant liquid recirculation pump 11, low temperature absorber 12, pressure reducing valve 13 and solution heat exchanger 14; Absorber 1 is connected to the low-temperature absorber 12 through the solution pump 6, the solution heat exchanger 14, and the pressure reducing valve 13 through the concentrated solution pipeline, connected with the condenser 3 through the refrigerant steam pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com