Light source module and lighting device for a vehicle

A technology for light source components and lamps, applied in the field of light source components and vehicle lamps, can solve problems such as the increase in the number of components, and achieve the effects of expanding the irradiation range and improving the luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the best mode for carrying out the light source unit and the vehicle lamp for carrying out the present invention will be described with reference to the accompanying drawings.

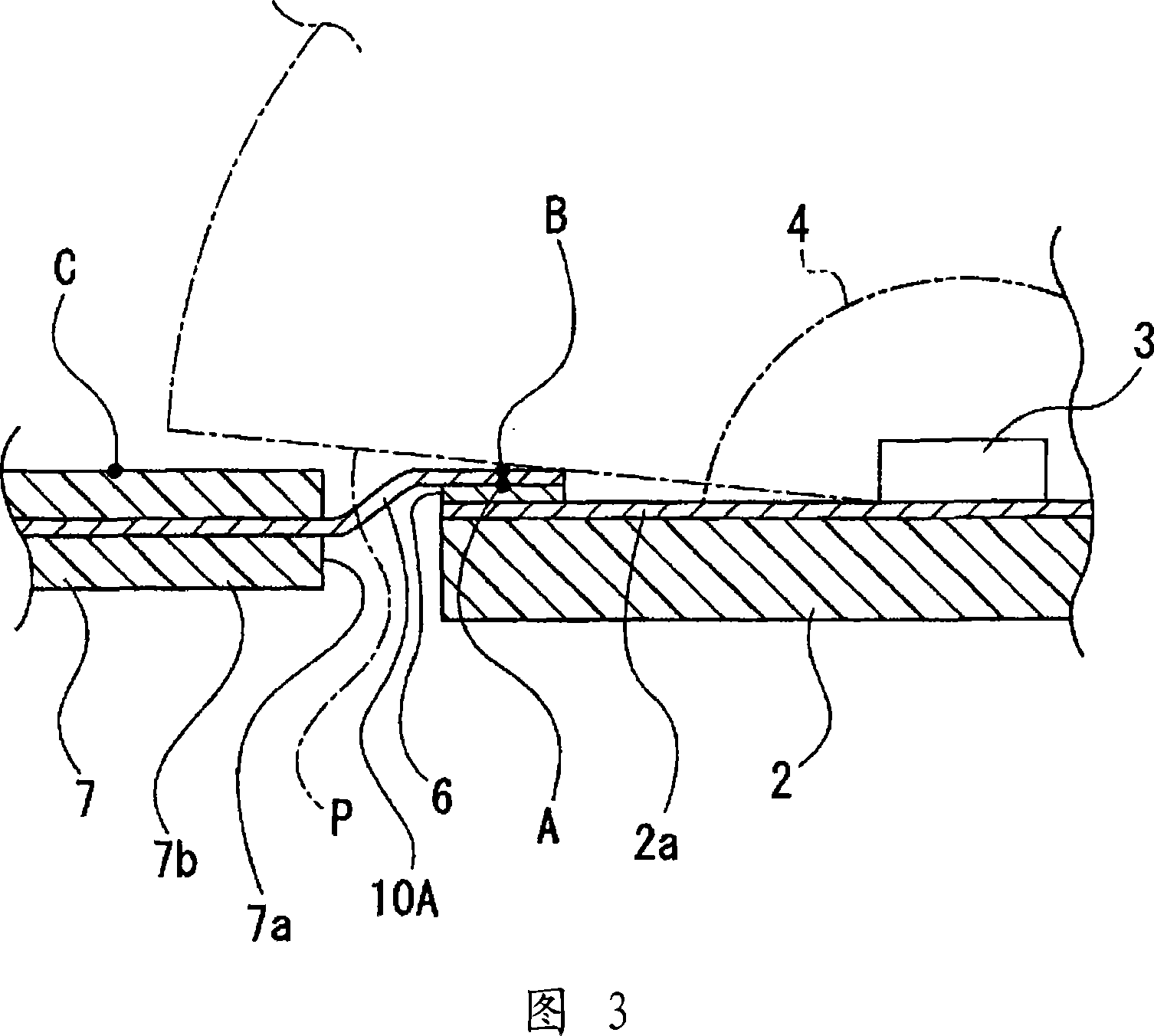

[0031] The light source unit 1 includes a ceramic circuit board 2, semiconductor light emitting elements 3 such as LED (light emitting diode) chips, a cover 4, and an attachment 5 for power supply (see FIG. 1 ).

[0032] For the ceramic circuit board 2 , for example, various substrates such as an aluminum nitride substrate, an alumina substrate, a mullite substrate, and a glass ceramic substrate can be used. On the ceramic circuit board 2, a pair of conductive patterns 2a, 2a extending from a central portion to side edges on opposite sides are formed.

[0033] Metal spacers 6 , 6 are bonded to end portions at respective outer positions of the conductive patterns 2 a , 2 a of the ceramic circuit board 2 . Since the metal spacers 6 and 6 are fixed to connection terminals of the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com