Light reflecting ceramic chip and preparation method thereof

A technology of reflective and ceramic sheets, applied in the directions of roads, safety islands, road signs, etc., can solve the problems of complex construction procedures, easy aging of reflective films, and small application scope, and achieve simple construction procedures, excellent anti-fading ability, and large application scope. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

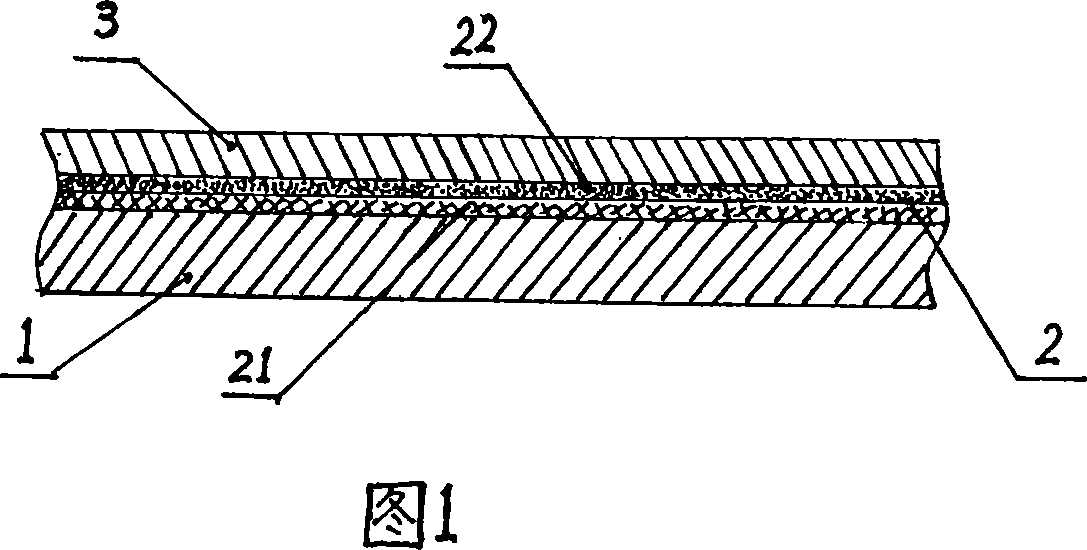

[0029] Fig. 1 constitutes a specific embodiment 1 of the present invention.

[0030] With reference to Fig. 1, present embodiment is made of tile bottom 1, reflective refraction layer 2 and transparent surface layer 3; The bottom layer 1 is compositely connected and formed, and the upper surface of the reflective refraction layer 2 is compositely connected and formed with the bottom surface of the transparent surface layer 3; the composite connected and formed structures can be sintered or bonded formed structures respectively.

[0031] In this embodiment: the reflective refraction layer 2 is composed of a reflective thin layer 21 and a refractive thin layer 22, the reflective thin layer 21 is compounded on the upper surface of the ceramic bottom layer 1, and the refractive thin layer 22 is compounded on the upper surface of the reflective thin layer 21 . The raw material layer of the reflective thin layer 21 is formed by the enamel and the aluminum-based silver powder mixtur...

specific Embodiment 2

[0038] The characteristics of this embodiment are: the blank layer of the reflective thin layer 21 is formed by the aluminum-based thin layer compounded on the surface of the ceramic base layer 1, and the blank layer of the refraction layer 22 is formed by the glass beads attached to the aluminum-based thin layer. The two blank layers are sintered to form the reflective thin layer 21 and the refraction layer 22 .

[0039] Its preparation method comprises the following steps:

[0040] 1) Selecting a ceramic chip of a predetermined specification as a carrier to form the bottom layer 1 of the ceramic chip;

[0041] 2) Mix evenly with low-temperature enamel and aluminum-based silver powder, apply the mixture on the surface of the tile to form a thin reflective green layer, and then evenly sprinkle glass beads on the aforementioned green layer to form a refractive layer green layer;

[0042] 3) Then send it into an oven for sintering, so that the reflective refraction layer 2 is f...

specific Embodiment 3

[0045] The characteristics of this embodiment are: it is made of porcelain bottom layer 1, reflective refraction layer 2 and transparent surface layer 3; Reflective refraction layer 2 is positioned between ceramic sheet bottom layer 1 and transparent surface layer 3, and the bottom surface of light reflective refraction layer 2 and ceramic sheet The bottom layer 1 is bonded and formed, and the upper surface of the reflective refraction layer 2 and the transparent surface layer 3 are bonded and formed.

[0046] The production method of this embodiment is:

[0047] 1) Selecting a ceramic chip of a predetermined specification as a carrier to form the bottom layer 1 of the ceramic chip;

[0048]2) Select a reflective film with the same specification as the ceramic sheet with reflective refraction function to form the reflective refraction layer 2;

[0049] 3) Select transparent glass with the same specifications as the tiles to form a transparent surface layer 3;

[0050] 4) App...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com