Needle loom in which the frequency of at least one of its vibration modes can be adjusted

A technology of inherent vibration, acupuncture machine, applied in the equal direction of acupuncture machine, textile and paper, edible oil/fat, can solve the problems of unsatisfactory, increased manufacturing cost, not acupuncture machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

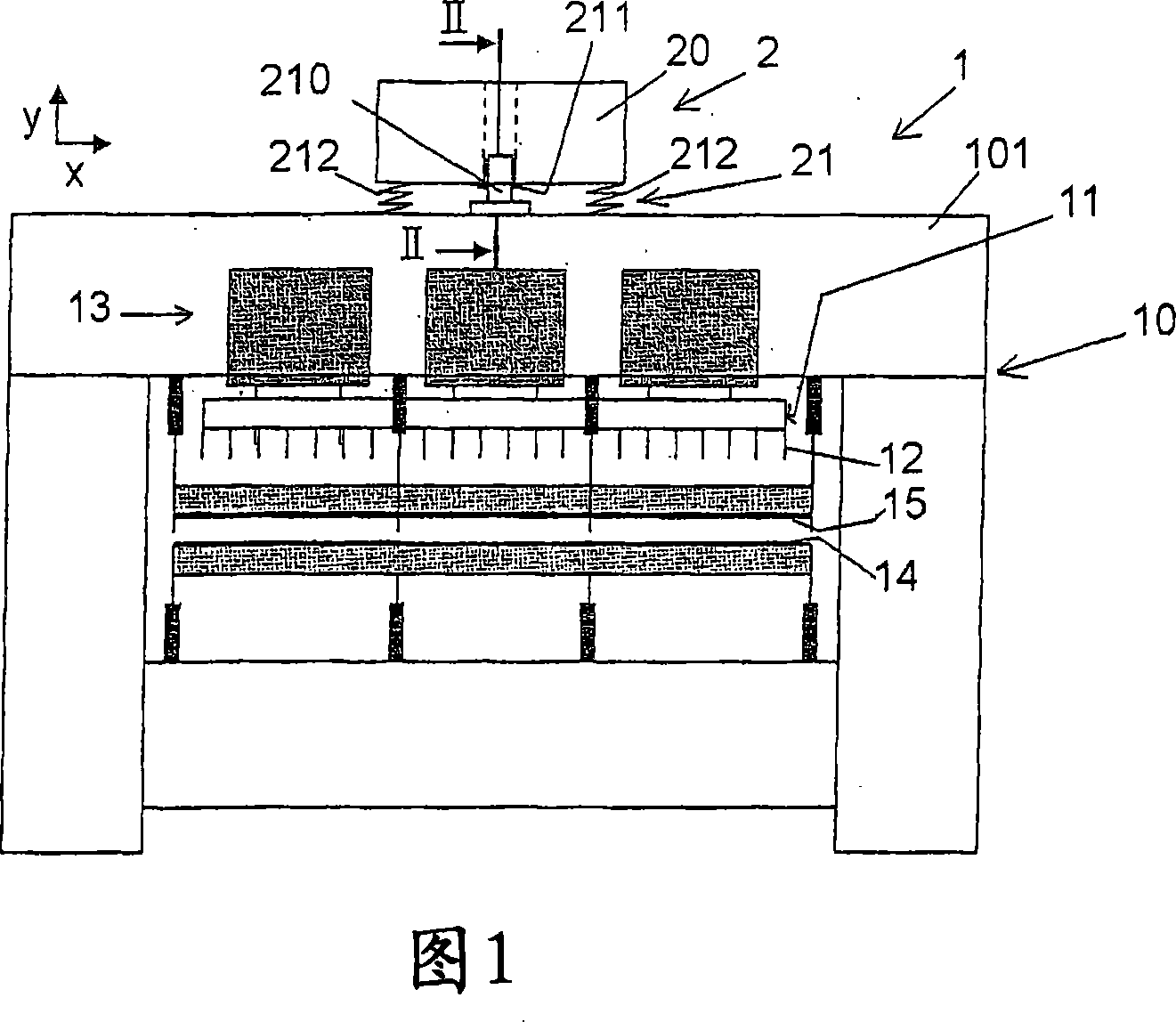

[0042] [42] Figure 1 shows a single-click needling machine 1 for needling any type of nonwoven fibrous product, for example for needling nonwovens which are conveyed upstream of the needling machine by an open-width-forming machine.

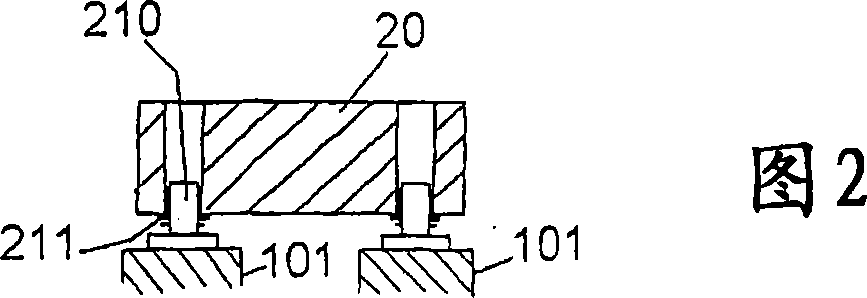

[0043] [43] The needling machine 1 is equipped with a special adjustment device 2 according to the invention.

[0044] [44] Acupuncture machine 1

[0045] [45] The structure and operation of the needling machine 1 are known and therefore only briefly described below.

[0046] [46] The acupuncture machine 1 comprises a mechanically welded type steel support frame 10 with:

[0047] [47] - a needle set 11 comprising a plurality of vertical needles 12;

[0048] [48] - Motorized (for example a motor connected to a crank-link assembly) drive means 13 capable of moving the needle set 11 according to a vertical alternating motion;

[0049] [49]-Two separate horizontally perforated steel plates 14 and 15, the holes of which are vertically aligned wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com