Machine tool with linear guide device and linear guide replacement method

A working machine and replacement method technology, which is applied in the direction of tool replacement devices, metal processing machine parts, mechanical equipment, etc., can solve the problems of large moving amount and large gap, and achieve the effect of reducing working procedures and simple and cheap device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described with reference to the drawings.

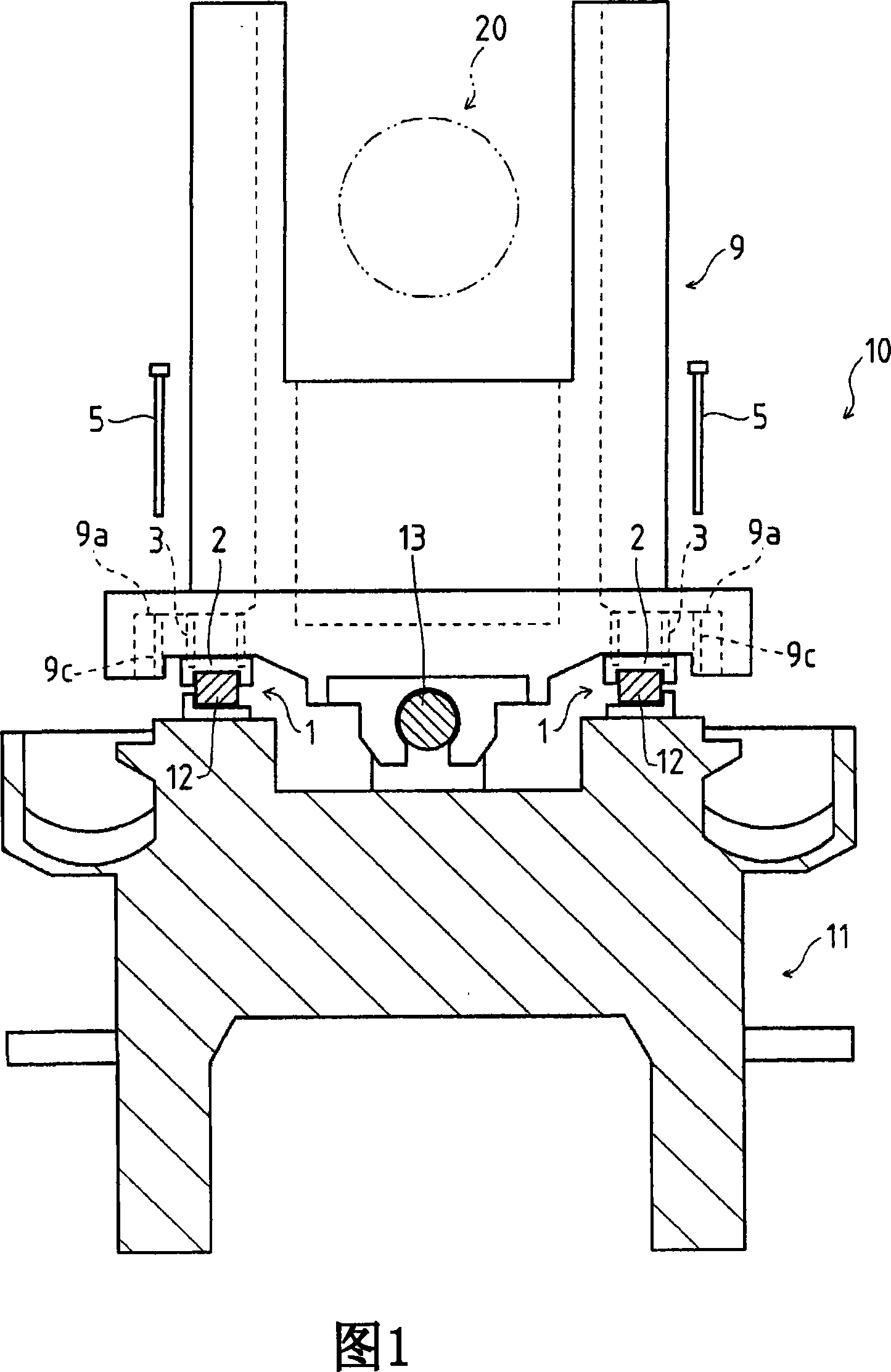

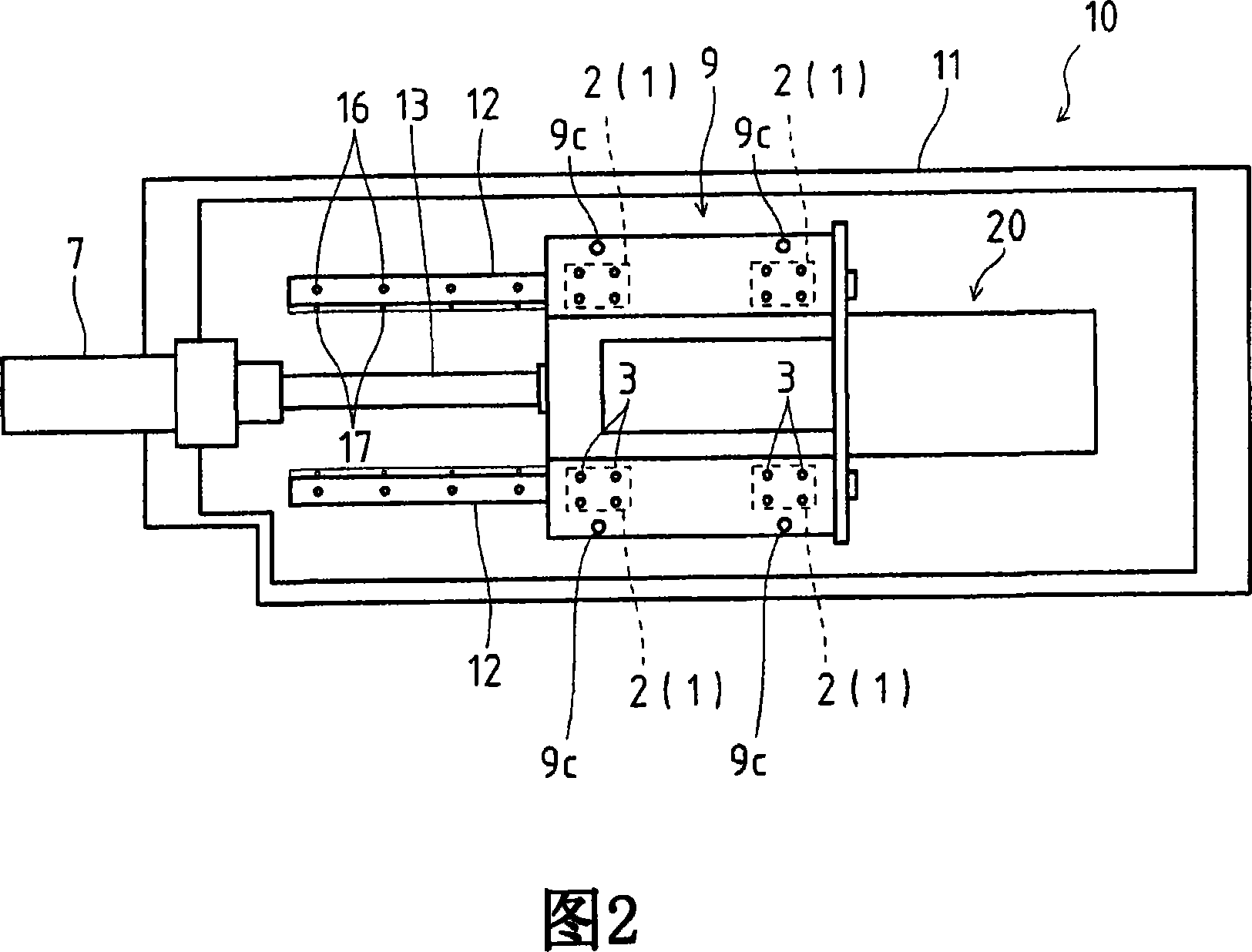

[0025] 1 and 2 are diagrams showing a machine tool 10 equipped with linear guide devices 1 and 1 according to the present invention. In FIG. On the guide rails 12, 12, the slide seat plate 9 as a moving body is provided via the linear guides 2, 2. In addition, a headstock 20 is attached to the slide seat plate 9 .

[0026] In addition, the sliding seat plate 9 moves in the left-right direction in FIG. 2 by the rotation of the ball screw 13 rotated by the motor 7 (refer to FIG. 2 ). 12 to guide the above-mentioned linear guides 2, 2 to perform linear motion.

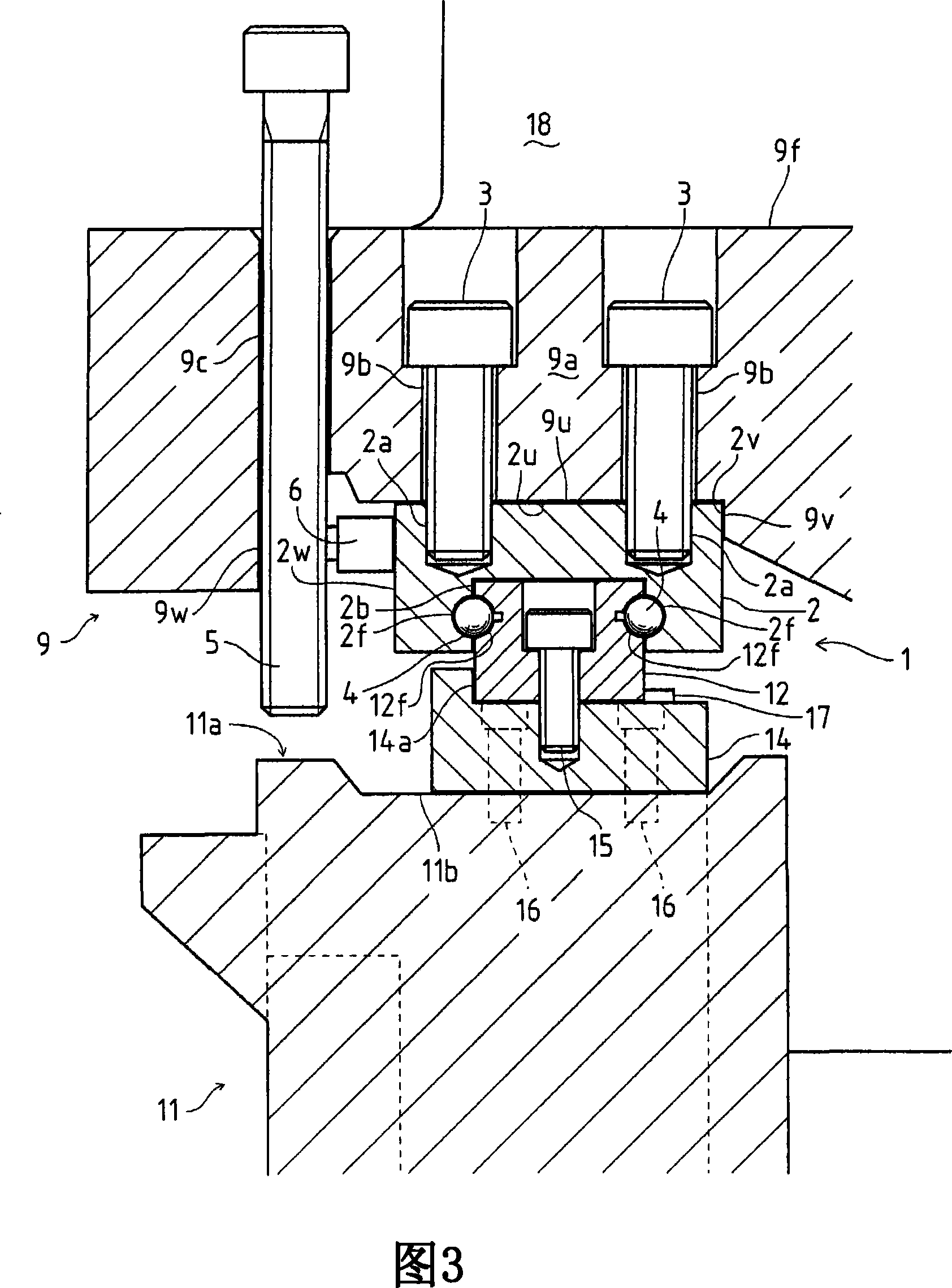

[0027] FIG. 3 is a diagram showing a specific structure of the linear guide device 1 according to the present invention, and a guide rail installation table 14 is fixedly mounted on the base 11 by fixing bolts 16 , 16 . Moreover, the guide rail 12 is fixedly mounted on the said guide rail installation stand 14 by the rail at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com