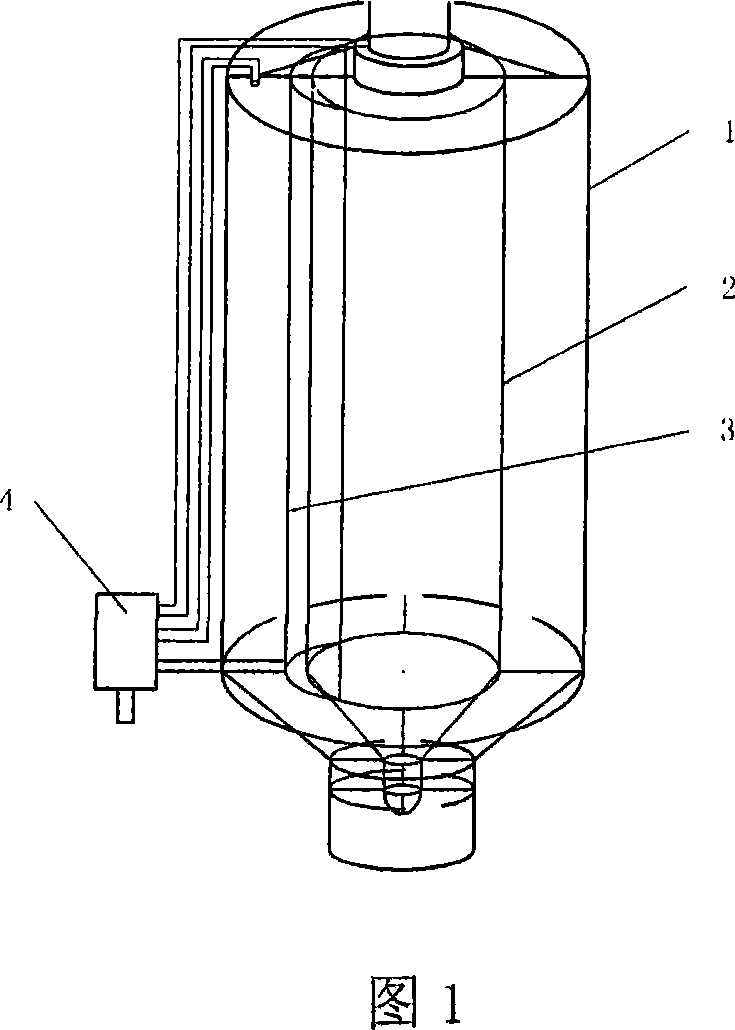

Self-flushing intermittent filter

A filter, intermittent technology, applied in the direction of mobile filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of cost and use range limitation, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

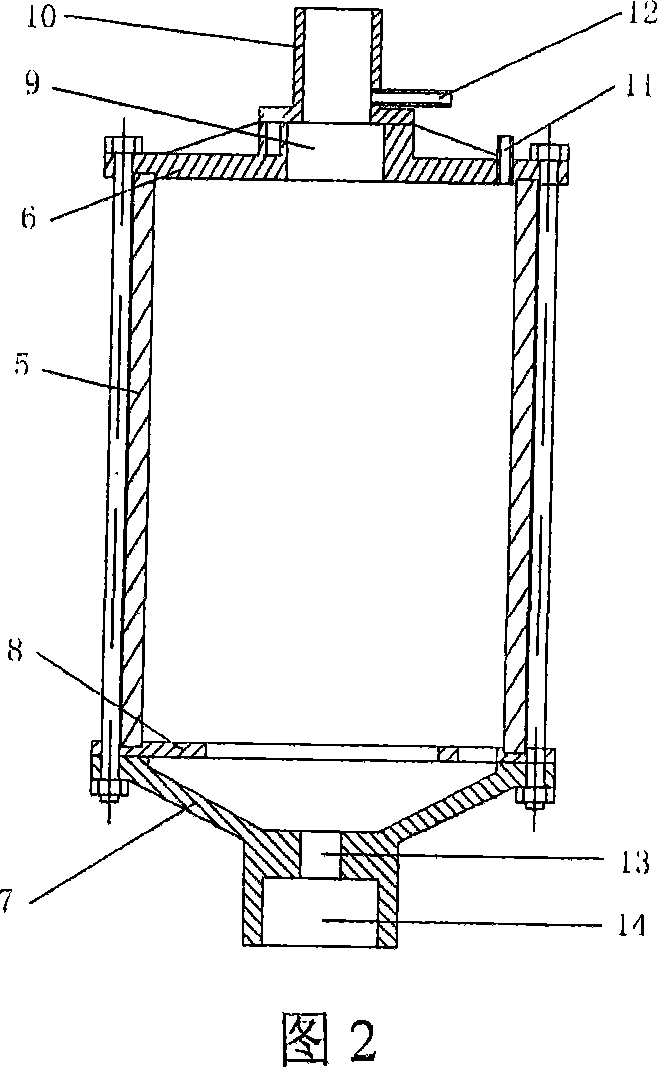

[0063] For the filtration of technical water supply commonly used in hydropower plants, the outlet pressure of the filter is 0.25MPa, the outlet flow rate is 1000m3 / h, and the filter particle diameter is 1mm.

[0064] The cylinder shell (5) in this filter Figure 2 is made of standard carbon steel with a thickness of 10mm rolled into a seamless steel pipe with a diameter of 1200mm and a height of 1200mm; the upper cover (6) and the lower cover of the housing in Figure 2 (7) All are made of standard carbon steel with corresponding thickness, the diameter and height are enlarged according to the size of the drawing, and the 8 bolts are Φ12mm standard bolts; Fig. 3 The filter element support (16) and the filter element upper cover (17) of the rotating filter element body 1. The lower cover (18) of the filter element body is made of non-toxic PVC plastics. The diameter of the upper and lower covers and the outer diameter of the cylindrical filter screen (20) are 800mm, and the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com