Dual three-level phase-shift high-voltage high-power frequency transformer

A three-level inverter and high-power technology, applied in the field of electric transmission, can solve the problems of large number of components, reduced efficiency of frequency converter, increased loss of absorption loop and static voltage equalizing resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and example the present invention is described in further detail.

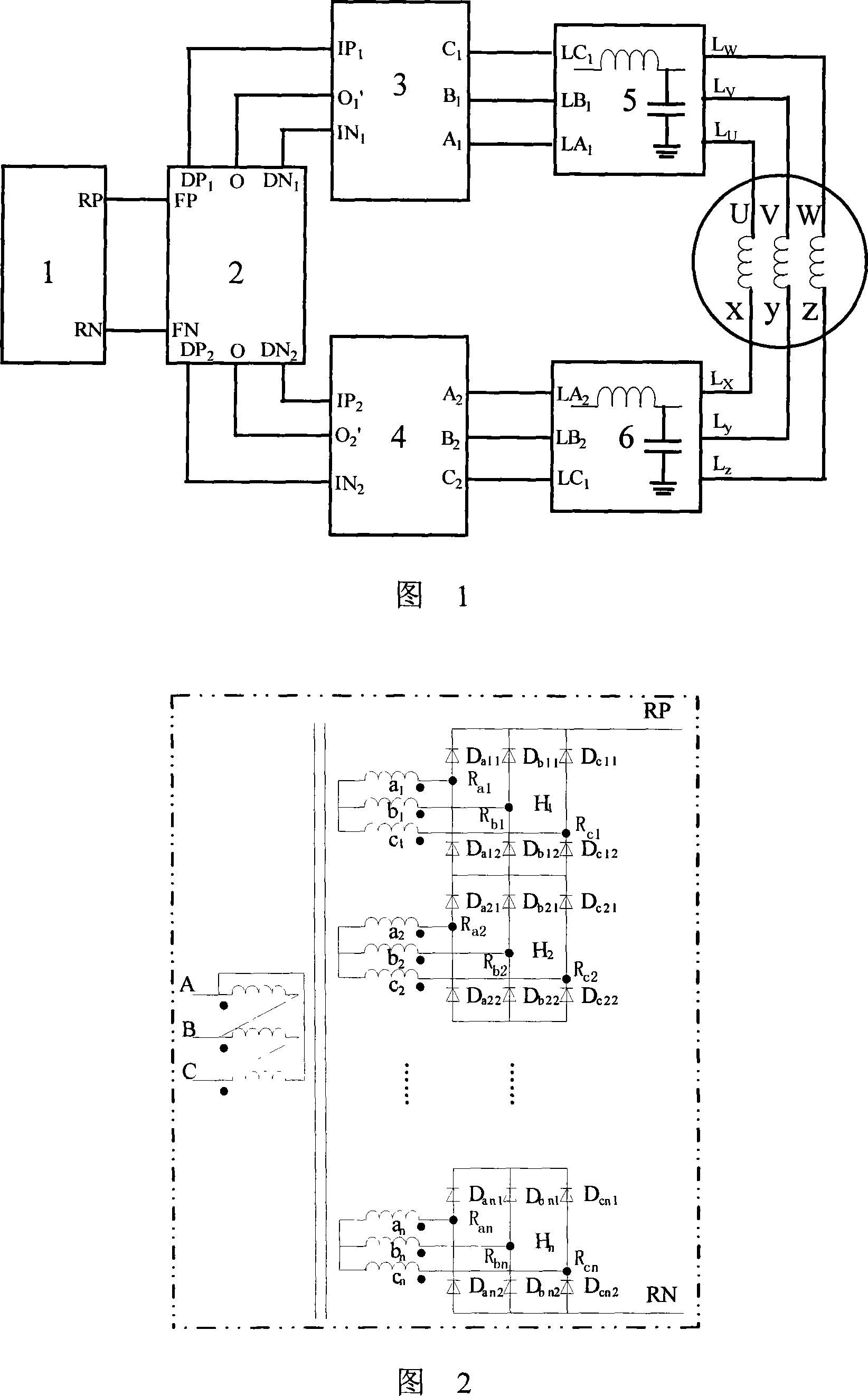

[0016] As shown in Fig. 1, the dual-three-level phase-shifting high-voltage high-power inverter of the present invention includes a rectification unit 1, a DC unit 2, a first three-level inverter unit 3, a second three-level inverter unit 4, a first An LC three-phase filter unit 5 and a second LC three-phase filter unit 6 . U-x, V-y, and W-z in FIG. 1 represent three-phase windings of the load motor 7, respectively. At present, the six terminals of the motor winding are all arranged on the terminal board on the motor casing, and it is only necessary to open the corresponding connection point and connect the wires as shown in Figure 1.

[0017] The positive and negative busbars RP and RN of the rectifier unit 1 are respectively connected to the positive and negative terminals FP and FN of the DC unit 2 . The first three-level inverter unit 3 is connected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com