Industrial fume purifying apparatus

A purification device and industrial technology, applied in chemical instruments and methods, using liquid separation agents, lighting and heating equipment, etc., can solve the problems of high cost of use, poor flue gas purification effect, no harmful gas or soot purification, etc. Achieve the effects of low cost of use, simple structure, and low cost of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

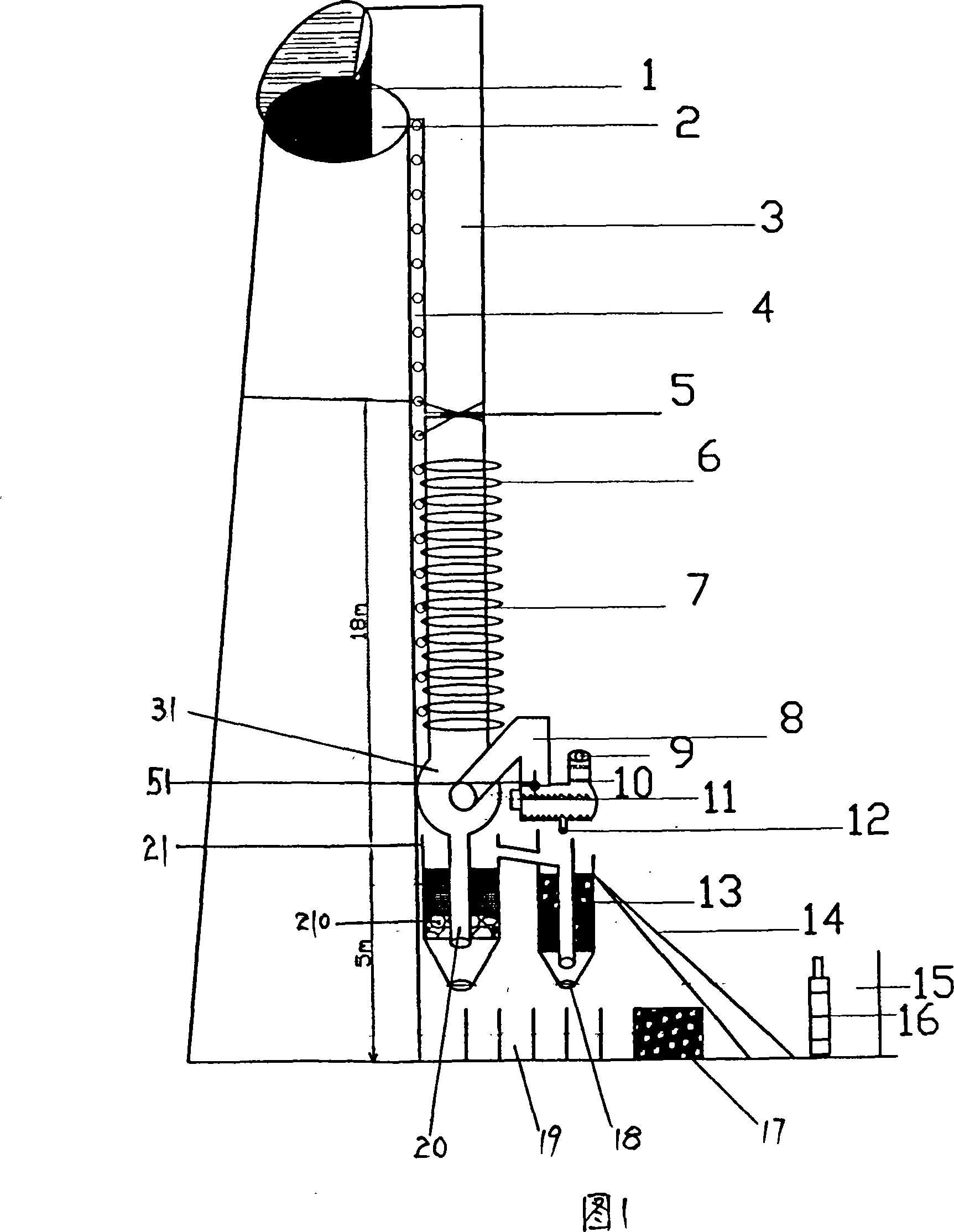

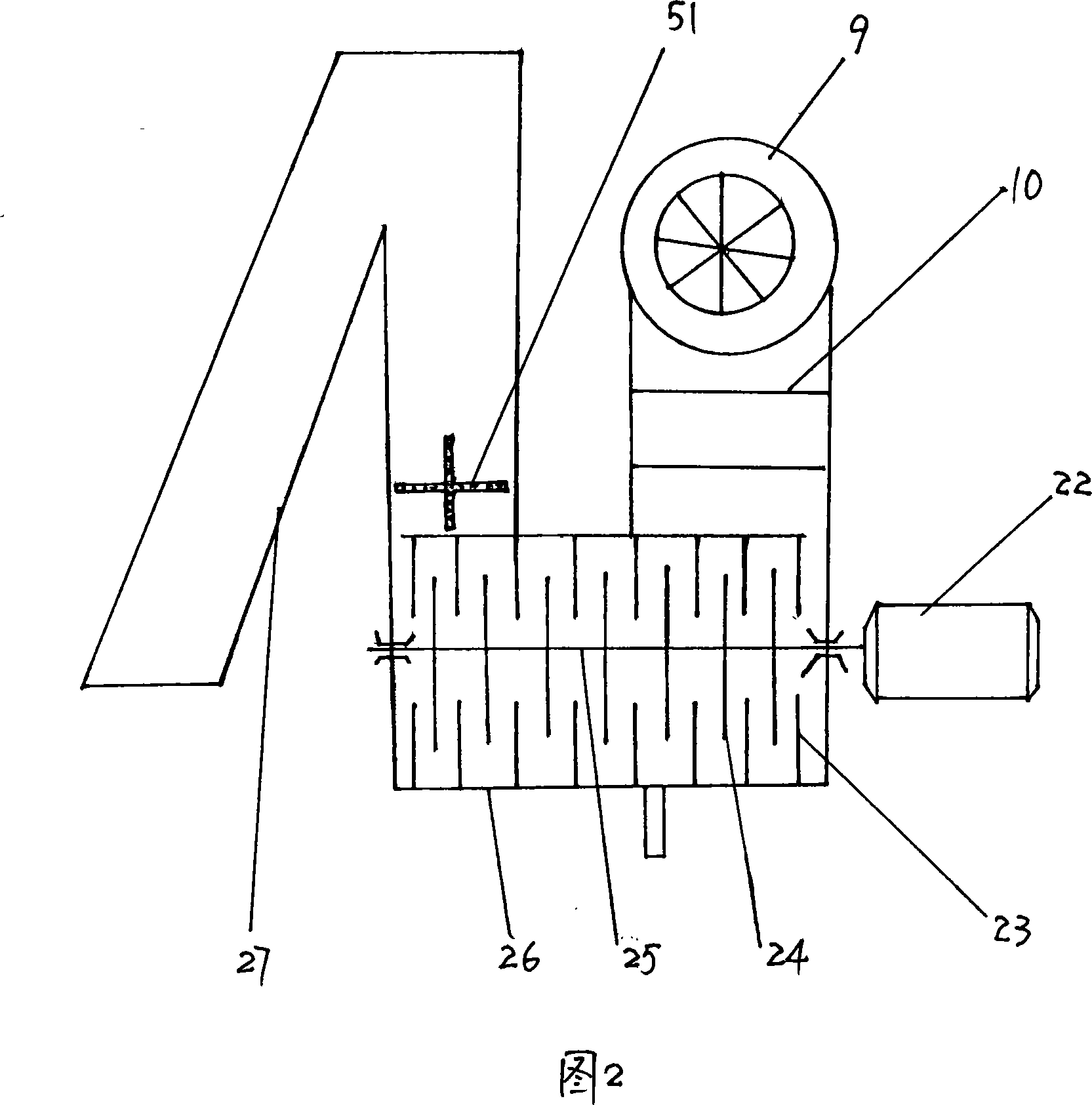

[0007] As shown in Figure 1 and Figure 2, an industrial smoke purification device is composed of a smoke guide pipe 3 and left and right filters. The smoke guide pipe communicates with the chimney mouth 1. Usually, the chimney mouth is sealed and divided into two outlets. One outlet communicates with the smoke guide pipe inlet, and the other outlet is the emergency smoke outlet 2. The emergency smoke outlet is provided with a sealing cover. Its function is When the present invention is not in use, it is used for emergency smoke exhaust, so that the chimney can be penetrated. There is a high-pressure water pipe 4 and a cross nozzle 5 connected to the high-pressure water pipe inside the smoke guide pipe. The downward angle between the cross nozzle and the horizontal is 40°-50°. The smoke guide pipe at the lower end of the cross nozzle is equipped with a belt-type electrostatic generator 6 The role of the belt-type electrostatic generator is to generate static electricity opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com