Method for preparing briented growth dielectric-constant adjustable strontium lead titanate film

A technology for adjusting the dielectric constant of lead strontium titanate is applied in the field of preparation of thin films of lead strontium titanate with adjustable dielectric constant, which can solve the problem of not easy large-scale practical application and industrialization, limiting the application range of materials and increasing the preparation cost. and other problems, to achieve the effect of promoting the crystallization process of PST, good market prospects, and expanding the preparation route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

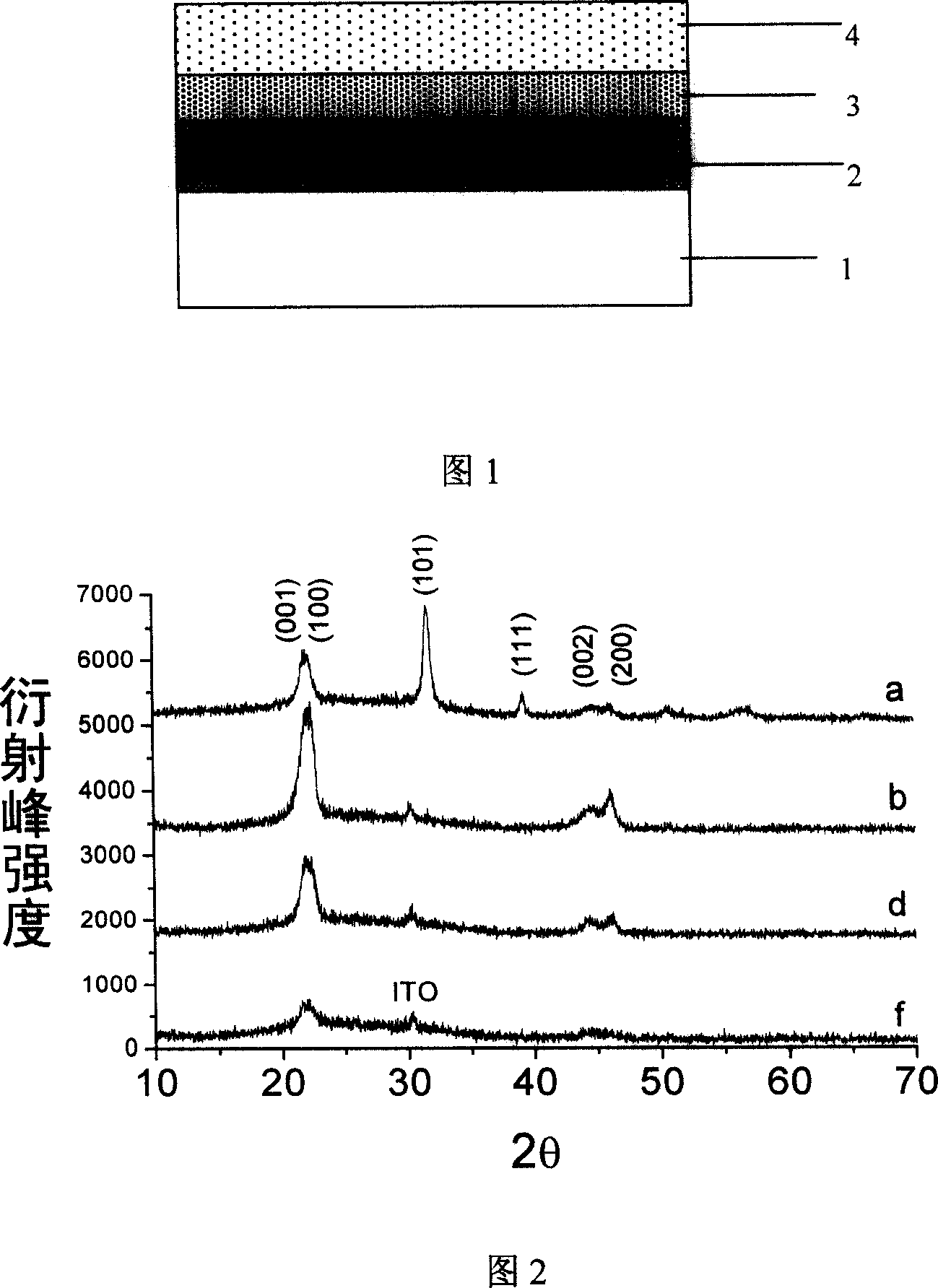

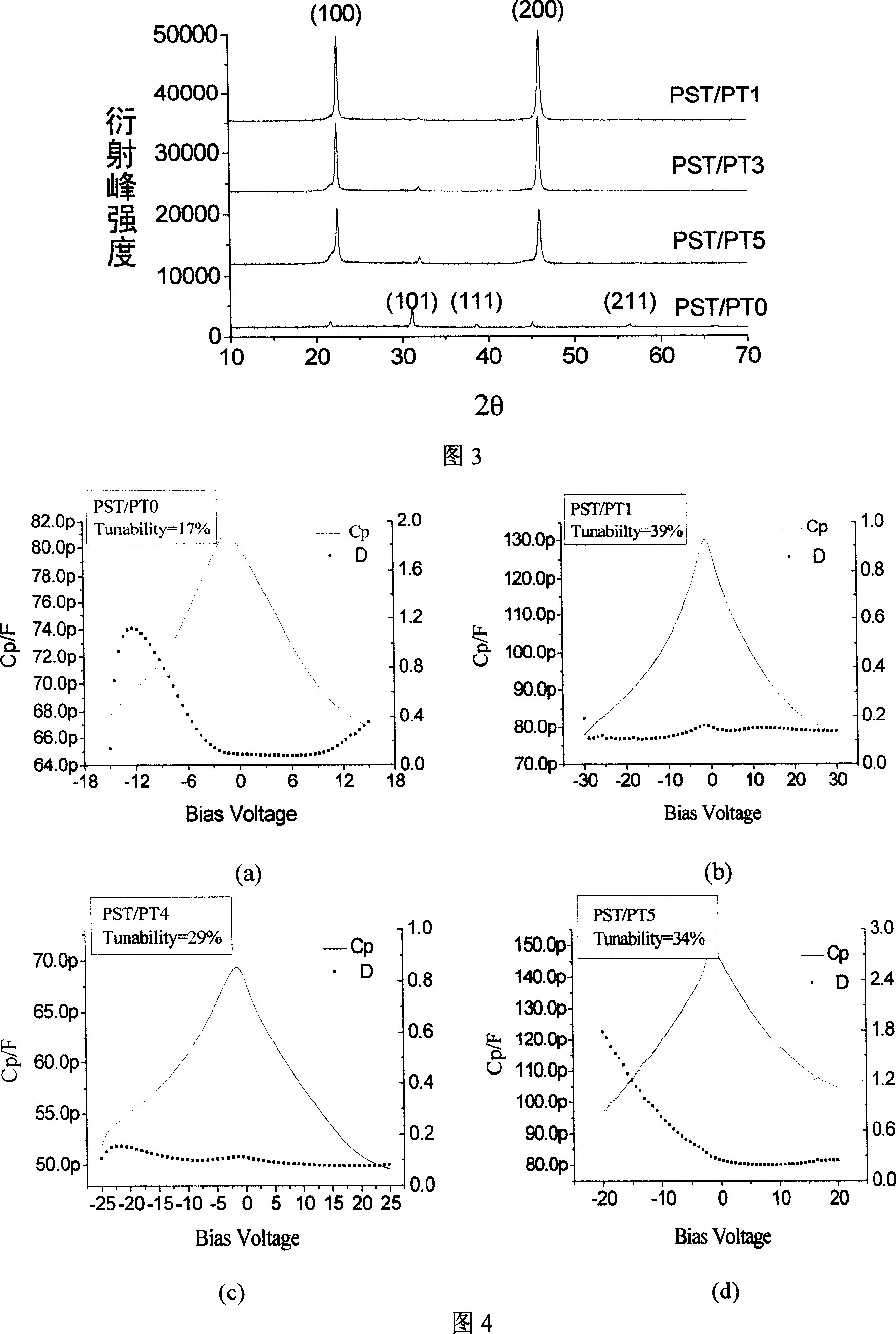

Image

Examples

Embodiment 1

[0029]Lead acetate is dissolved in ethylene glycol methyl ether, and the concentration of Pb after heating to 80°C and stirring to dissolve is 0.2mol / L. Butyl titanate is dissolved in ethylene glycol methyl ether, and the concentration is 0.2mol / L after stirring evenly. Then the two solutions are mixed, add glacial acetic acid with a volume ratio of 1:8 to the mixed solution, continue to stir for 10 minutes, then add terbium chloride ethanol solution in a 2% ratio, and finally adjust the concentration with ethylene glycol methyl ether to obtain Pb-Ti -Te precursor sol, the concentrations of the three components are: Pb, 0.1mol / L; Ti, 0.1mol / L; Te, 0.002mol / L. Stand for 48h for use. A 2.5cm×4.5cm ITO glass substrate was ultrasonically oscillated with 0.25mol / L NaOH solution at room temperature for 15min, rinsed with deionized water, and ultrasonically oscillated in alcohol for 15min to obtain a substrate with a clean surface. Using the static sol mentioned above, the sol-coate...

Embodiment 2

[0032] Lead acetate is dissolved in ethylene glycol methyl ether, and the concentration of Pb after heating to 80°C and stirring to dissolve is 1.5mol / L. Butyl titanate is dissolved in ethylene glycol methyl ether, and the concentration is 1.5mol / L after stirring evenly. Then the two solutions are mixed, add glacial acetic acid with a volume ratio of 1:4 to the mixed solution, continue to stir for 10 minutes, then add terbium chloride ethanol solution in a 4% ratio, and finally adjust the concentration with ethylene glycol methyl ether to obtain Pb-Ti -Te precursor sol, the concentrations of the three components are: Pb, 0.4mol / L; Ti, 0.4mol / L; Te, 0.016mol / L. Stand for 48h for use. A 2.5cm×4.5cm ITO glass substrate was ultrasonically oscillated with 0.25mol / L NaOH solution at room temperature for 15min, rinsed with deionized water, and ultrasonically oscillated in alcohol for 15min to obtain a substrate with a clean surface. Using the above standing sol, use the method of ve...

Embodiment 3

[0035] Lead acetate is dissolved in ethylene glycol methyl ether, heated to 80°C and stirred to dissolve, and the Pb concentration is 0.8mol / L. Butyl titanate is dissolved in ethylene glycol methyl ether, and the concentration is 0.8mol / L. Then the two solutions are mixed, add glacial acetic acid with a volume ratio of 1:6 to the mixed solution, continue to stir for 10 minutes, then add terbium chloride ethanol solution in a 1% ratio, and finally adjust the concentration with ethylene glycol methyl ether to obtain Pb-Ti -Te precursor sol, the concentrations of the three components are: Pb, 0.25mol / L; Ti, 0.25mol / L; Te, 0.0025mol / L. Stand for 48h for use. A 2.5cm×4.5cm ITO glass substrate was ultrasonically oscillated with 0.25mol / L NaOH solution at room temperature for 15min, rinsed with deionized water, and ultrasonically oscillated in alcohol for 15min to obtain a substrate with a clean surface. Using the above standing sol, use the method of vertical pulling on the clean s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com