Method for extracting penicillin by magnetic ion liquid and reactor

A magnetic ionic liquid, ionic liquid technology, applied in organic chemistry and other directions, can solve the problems of organic solvent loss, environmental pollution, explosion danger, etc., to prevent emulsification, low shear force, and enhance mass transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: magnetic ionic liquid [bmim]FeCl 4 The result of extracting penicillin (using a three-blade propeller to stir)

[0040] 15ml of penicillin solution with a penicillin content of 1g / 100ml and 10ml of magnetic ionic liquid [bmim]FeCl 4 mix. Stir with a propeller at a speed of 300 rpm. Slight emulsification phenomenon after 10 minutes, centrifuged for 5 minutes, the extraction system was layered, and the upper aqueous phase and the lower ionic liquid phase were taken respectively. The aqueous phase solution was analyzed by polarimeter for penicillin content, and the ionic liquid phase was analyzed for penicillin content by high-performance liquid chromatography. The extraction rate of penicillin by ionic liquid was 76.65%.

Embodiment 2

[0041] Embodiment 2: magnetic ionic liquid [bmim]FeCl 4 The implementation results of extracting penicillin (using a reactor with rotating and lifting magnetic stirring isolation tank)

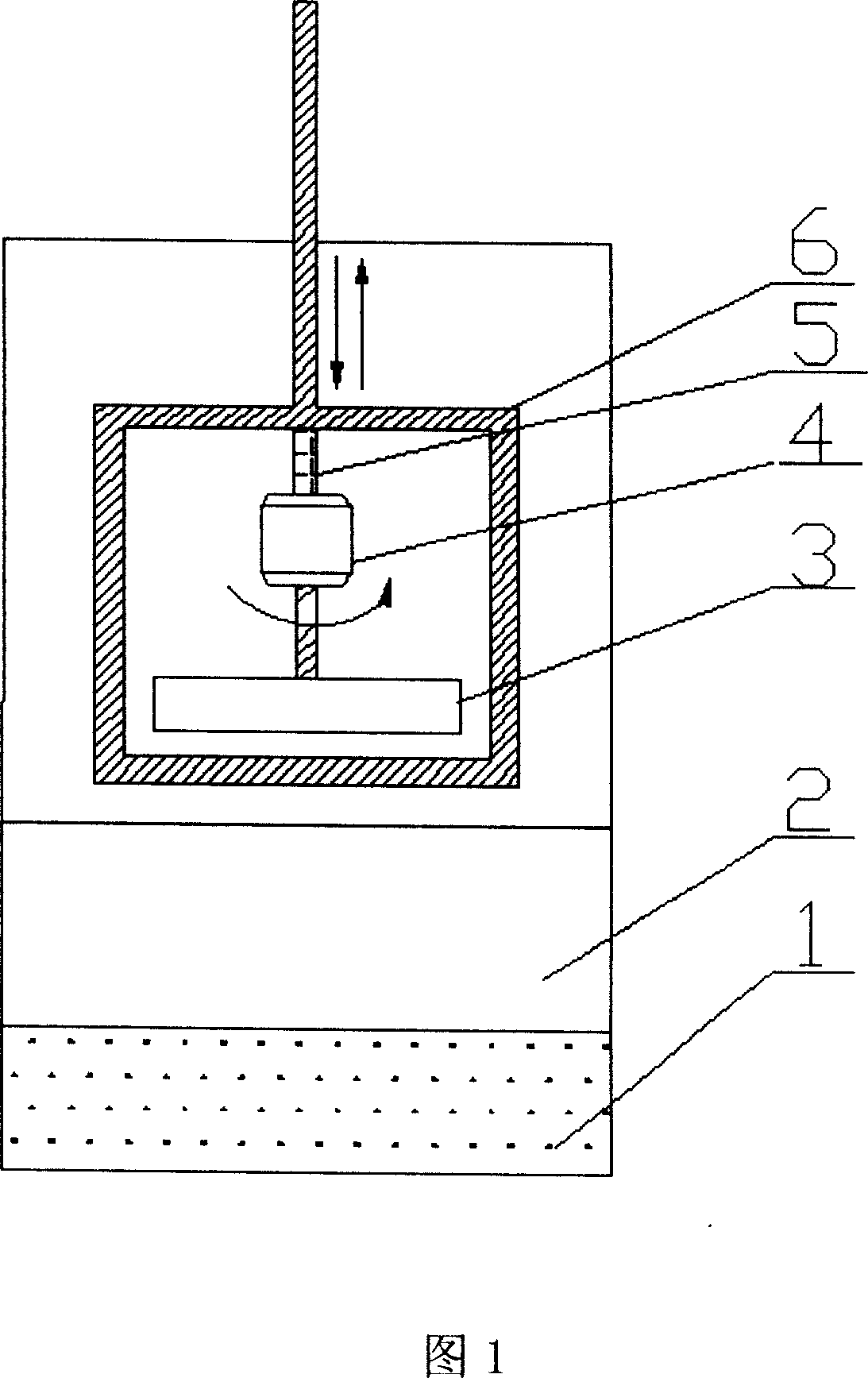

[0042] Please refer to Figure 1. An isolation tank 6 is installed in the reactor, and a rotary motor 4 is connected with a shaft 5 in the isolation tank 6. The bearing at one end of the rotary motor 4 is connected with the NdFeB permanent magnet 3, and the upper outer shell of the isolation tank 6 is connected with a sliding shaft. .

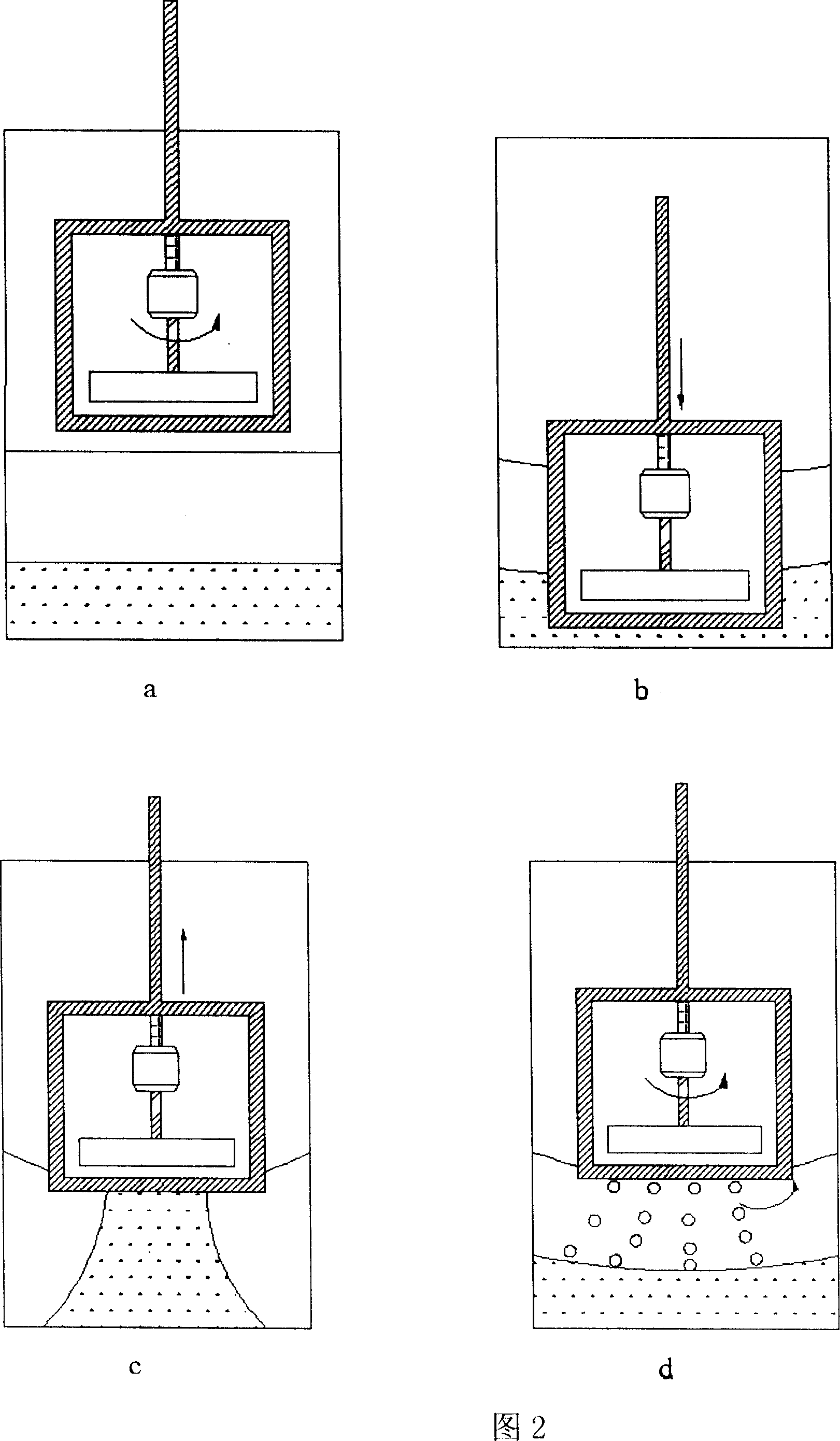

[0043] 15ml of penicillin solution with a penicillin content of 1g / 100ml and 10ml of magnetic ionic liquid [bmim]FeCl 4 mix. As shown in Figure 2a, the magnetic ionic liquid and the penicillin solution in the reactor are in a layered state after mixing, the ionic liquid is in the lower layer 1, and the penicillin solution is in the upper layer 2; the upper part is a rotating and lifting magnetic stirring isolation tank; as shown in Figure 2b , turn on the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com