Grinder level finisher

A dresser and level technology, applied in the directions of grinding machine parts, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of low dressing precision, low dressing efficiency, increase the height of the whole machine, etc. Simple, reduce production costs and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

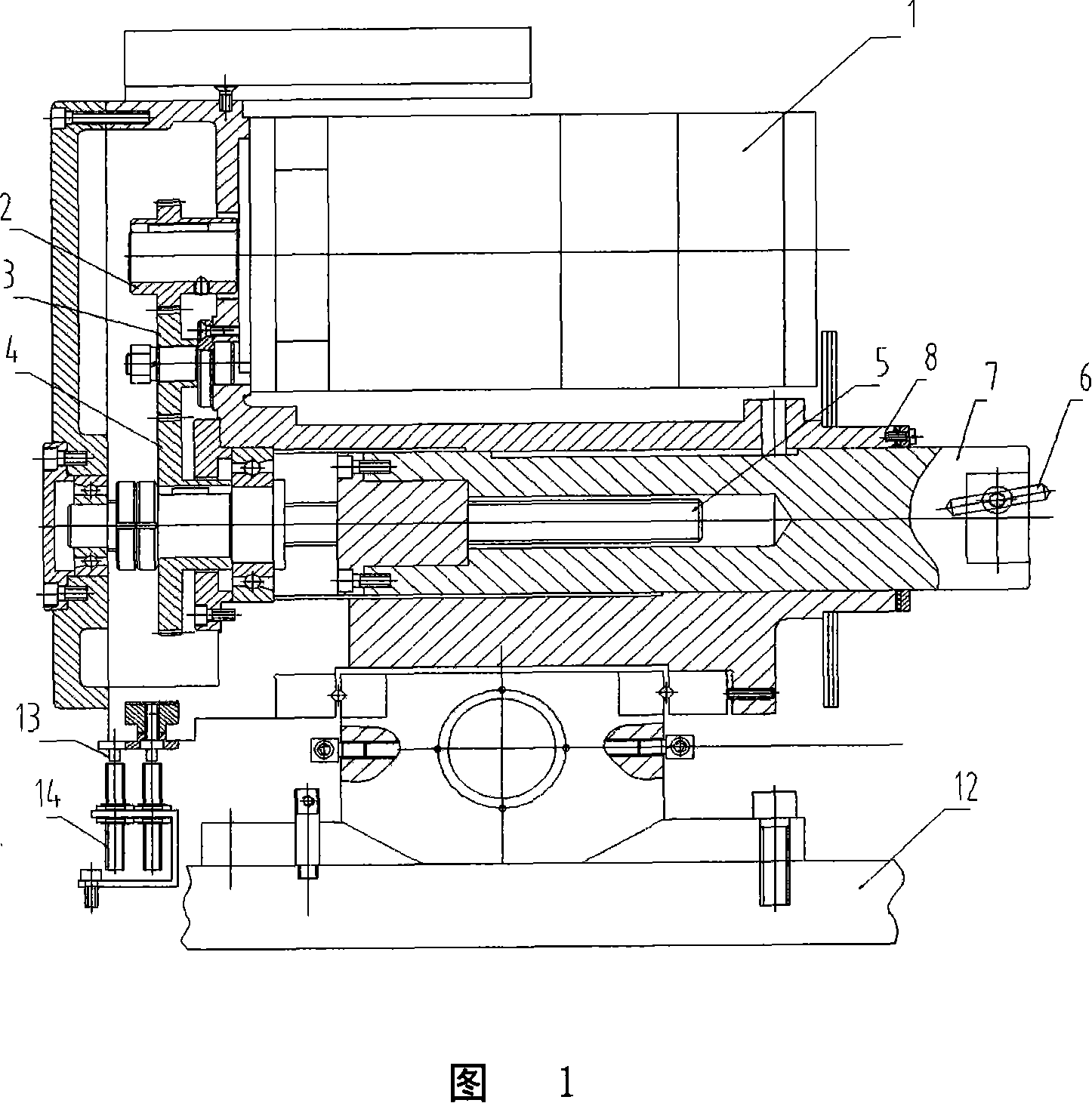

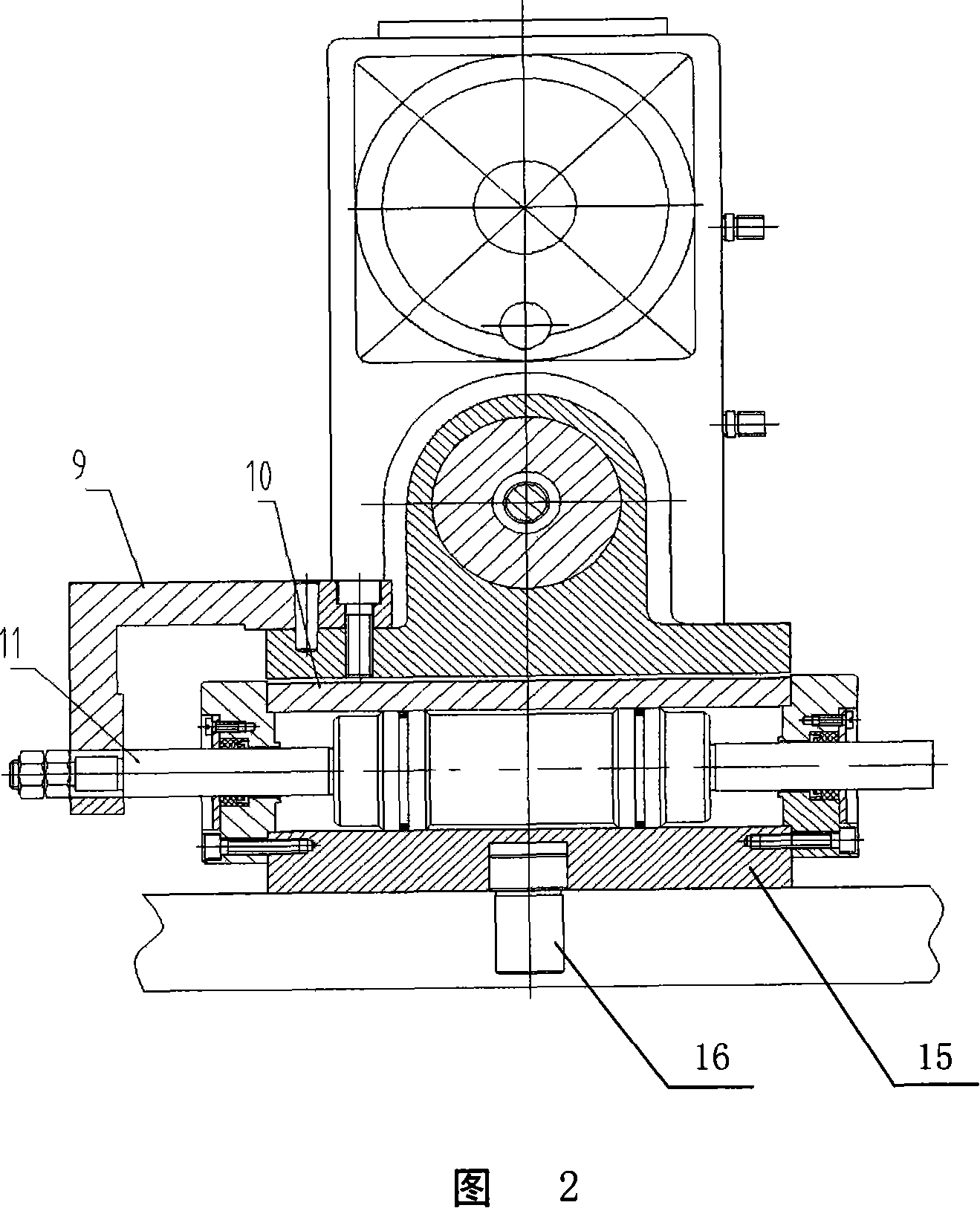

[0016] With reference to the accompanying drawings, this embodiment includes a feeding device and a hydraulic trimming device, the feeding device includes a motor 1, and the gear II 3 is installed on the housing 8, and is respectively connected with the gear I 2 installed on the motor 1 and fixed on the ball The gears III and 4 on the screw pair 5 are meshed, the shaft rod 7 is connected with the ball screw pair 5, and the diamond tool 6 is fixed on the shaft rod 7; the hydraulic trimming device includes a piston 11, which is installed in the oil cylinder 15 and can be Push the piston 11 to reciprocate, the signal block 13 is fixed on the housing 8, and is connected with the trigger signal switch 14 (by triggering the signal switch 14, the movement direction of the piston 11 can be changed); the two ends of the connecting block 9 are respectively fixed on the piston 11 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com