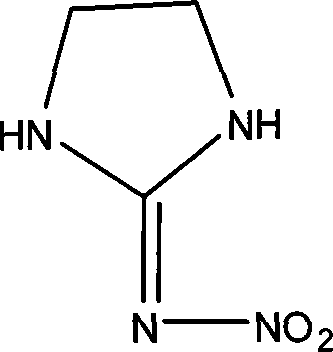

Prepn process of 2-nitro imido imidazolyl alkane

A technology of nitroiminoimidazolidine and nitroguanidine, which is applied in the field of preparation of 2-nitroiminoimidazolidine, can solve the problem of low yield of 2-nitroiminoimidazolidine, low yield, potassium hydroxide Problems such as high cost of raw materials, to achieve the effect of good product quality, high reaction yield, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

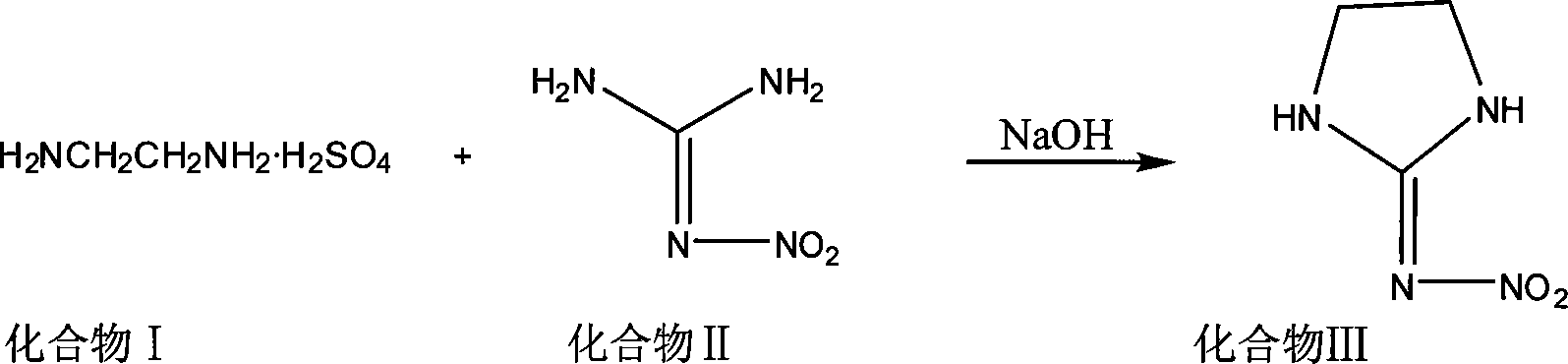

Method used

Image

Examples

Embodiment 1

[0018] Pump 150Kg ethylenediamine and 300Kg water into a 1000L reactor, add concentrated sulfuric acid dropwise to neutrality under freezing, put in 260Kg nitroguanidine, stir evenly, add 30% liquid caustic soda dropwise until the pH is 9, heat up to 60°C, and react After 6 hours, cool to room temperature, shake and filter to obtain a wet product, and dry to obtain a 254Kg finished product (above the content of 99%).

Embodiment 2

[0020] Pump 150Kg ethylenediamine and 300Kg water into a 1000L reactor, add concentrated sulfuric acid dropwise to neutrality under freezing, put in 260Kg nitroguanidine, stir well, add 30% liquid caustic soda dropwise until the pH is 10, heat up to 45°C, and react After 2 hours, cool to room temperature, shake and filter to obtain a wet product, and dry to obtain a 243Kg finished product (more than 99% content).

Embodiment 3

[0022] Pump 150Kg ethylenediamine and 300Kg water into a 1000L reactor, add concentrated sulfuric acid dropwise to neutrality under freezing, put in 260Kg nitroguanidine, stir evenly, add 30% liquid caustic soda dropwise until the pH is 8, heat up to 80°C, and react After 10 hours, cool to room temperature, shake and filter to obtain a wet product, and dry to obtain a 230Kg finished product (more than 99% content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com