Caliper for a disk brake

A technology of disc brakes and brake calipers, which is applied in the direction of brake actuators, rotating bearings, slack adjusters, etc., can solve the problems of impracticality, large component stress of adjustment devices, high manufacturing costs, etc., and achieve low load The effect of leveling, simplifying assembly and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

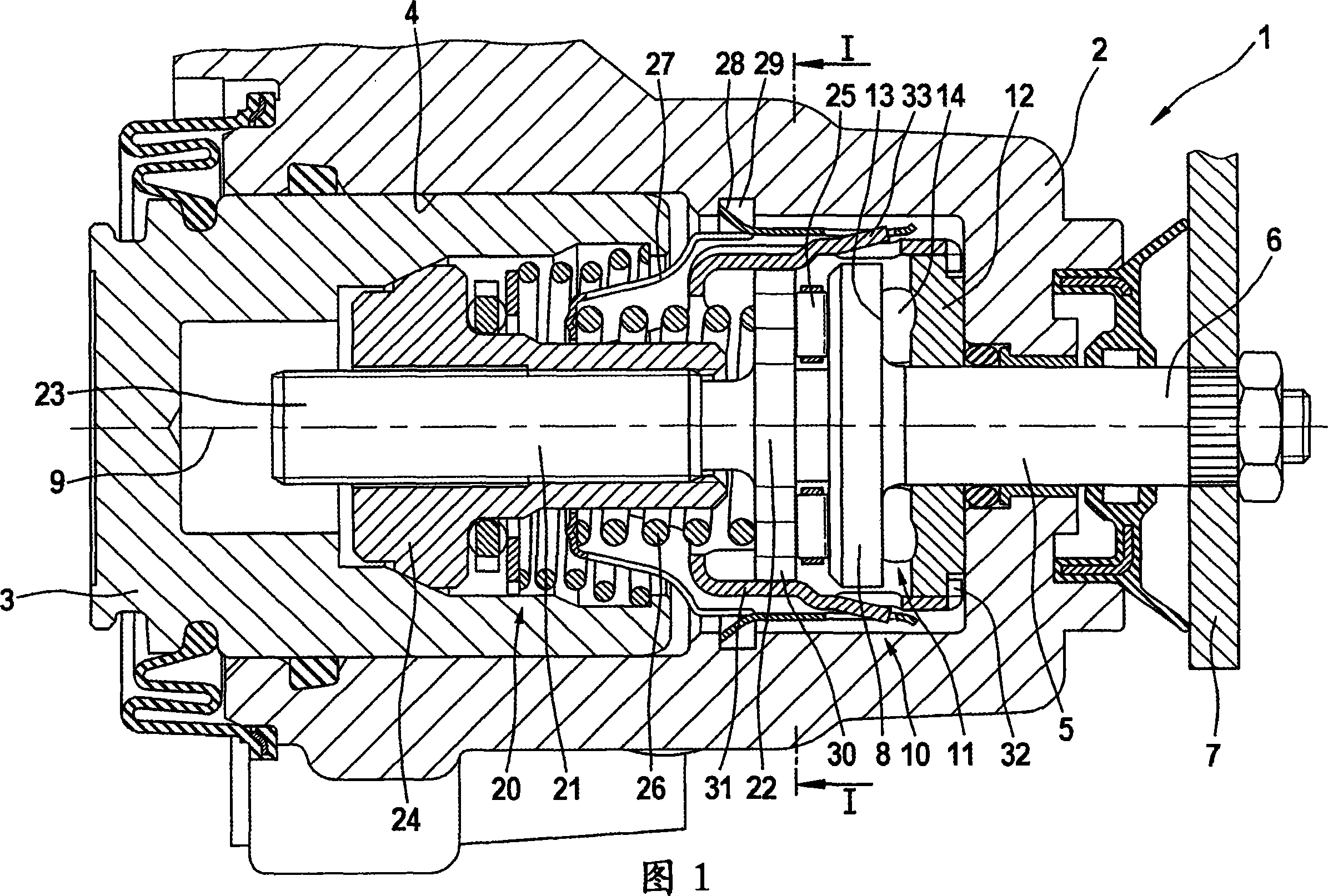

[0029] The brake caliper 1 of the motor vehicle disc brake shown in FIG. 1 particularly comprises a housing 2 and a piston 3 which is movably arranged in a hole 4 for braking operation. In the case of a normal braking operation, the piston 3 can be moved by hydraulic action. In order to achieve the parking brake, a shaft 5 is provided, which allows the piston 3 to move in the bore 4 through the actuating device 10. The shaft 5 extends through an opening of the housing 2 with a shaft end 6, and a lever 7 is installed on the shaft end 6. The actuating device 10 acts on the piston 3 by connecting an adjusting device 20 with a variable length in the middle.

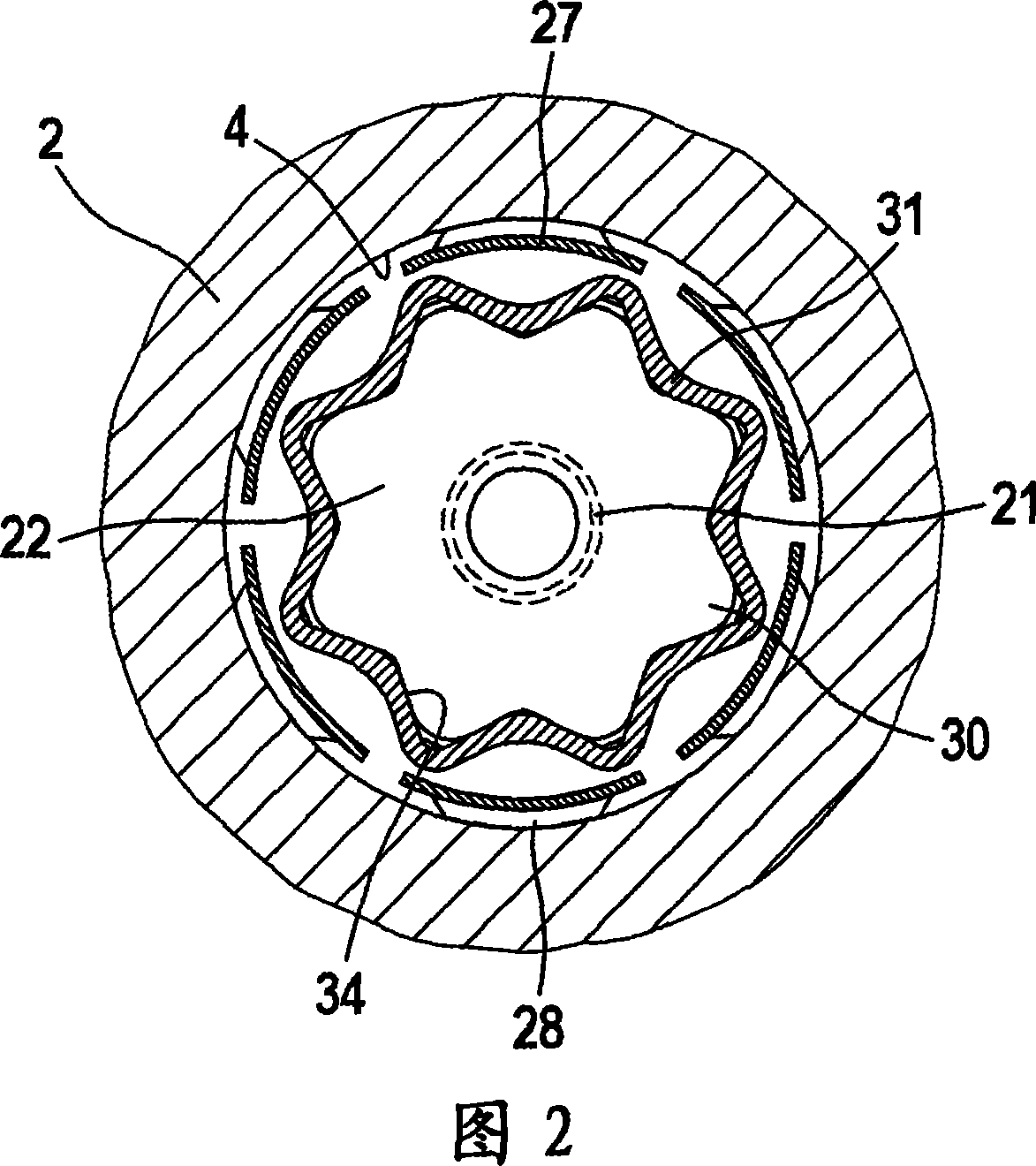

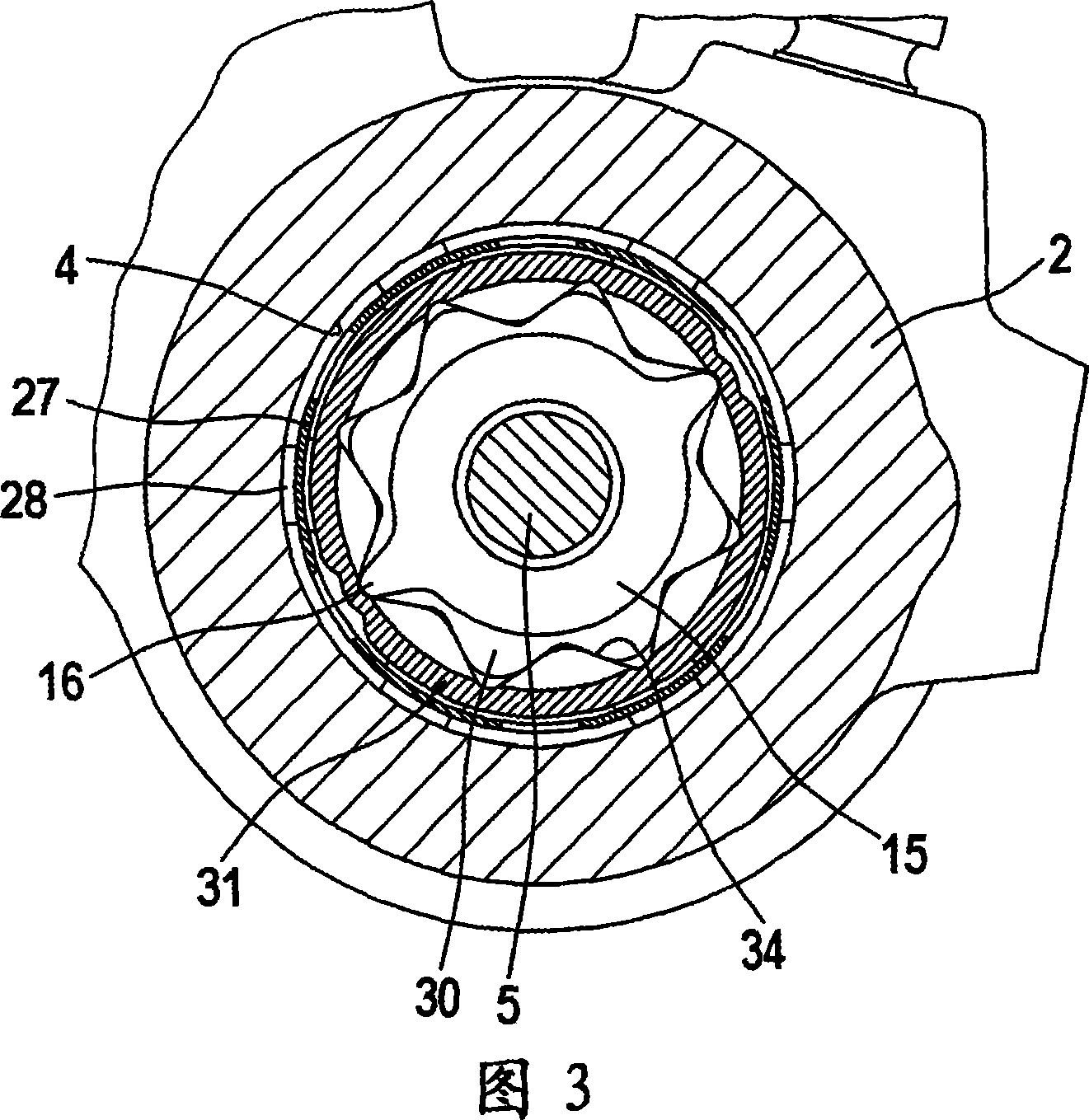

[0030] The actuating device 10 includes a ramp structure 11 having a ramp element 12 fixed on the housing and a ramp element 13 rotatable relative to the ramp element 12. At this time, the ramp element 13 is integrally formed on the disc-shaped end 8 of the shaft 5. A plurality of rolling bodies 14 are provided between the ramp e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com