Drive unit for X-ray system

A drive unit and X-ray technology, applied in the field of X-ray devices, can solve the problems of no detectable feedback, insufficient positioning of X-ray tubes, etc., and achieve good feedback, precise and direct movement control, and direct control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

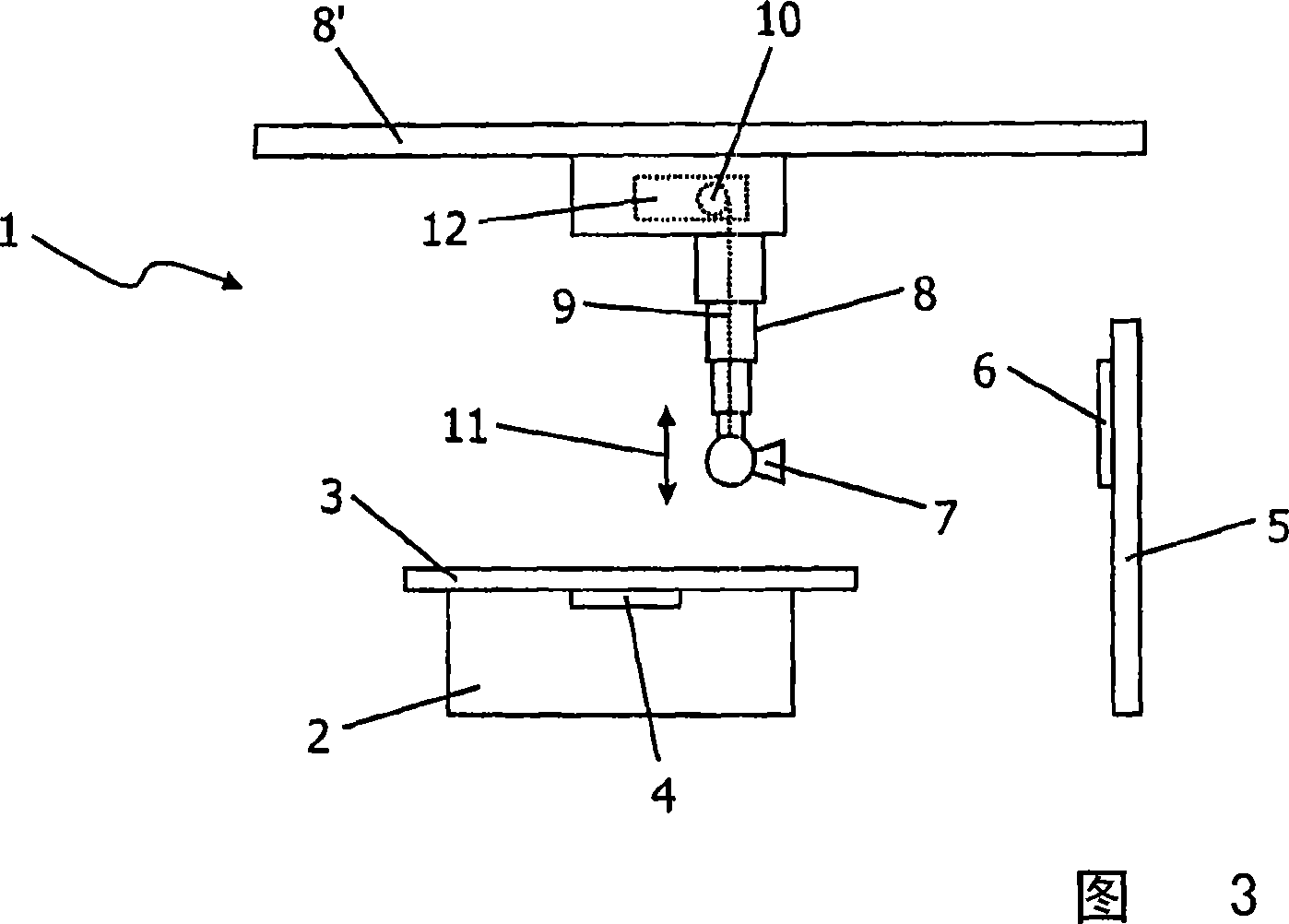

[0019] Referring to Fig. 3, an X-ray device 1 according to the invention is depicted. The X-ray apparatus 1 comprises a table 2 with a table top 3 for supporting a patient during an examination. The table 2 has a container 4 for X-ray film. Furthermore, a ledge 5 is provided, which also includes a container 6 for X-ray film. Such a ledge 5 can be used for examination of the patient in a standing position. An overhead x-ray source 7 directs the beam through the patient to the x-ray film below or behind the patient. The X-ray source 7 is mounted on a tube hanger 8 to support the X-ray source 7 and to enable the X-ray source 7 to move vertically and horizontally. The tube hanger 8 of the described x-ray device 1 can be extended or retracted via a telescopic section. These telescoping sections are telescopically movable by wires 9 which are guided by pipe hangers 8 and wound around pulleys 10 . The x-ray source can be raised or lowered (as indicated by arrow 11 ) by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com