Micro-domain heating apparatus

A heating device and micro-domain technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of large temperature difference in the heating area, and achieve the effects of large working area, simple heating device, and large working flow rate range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

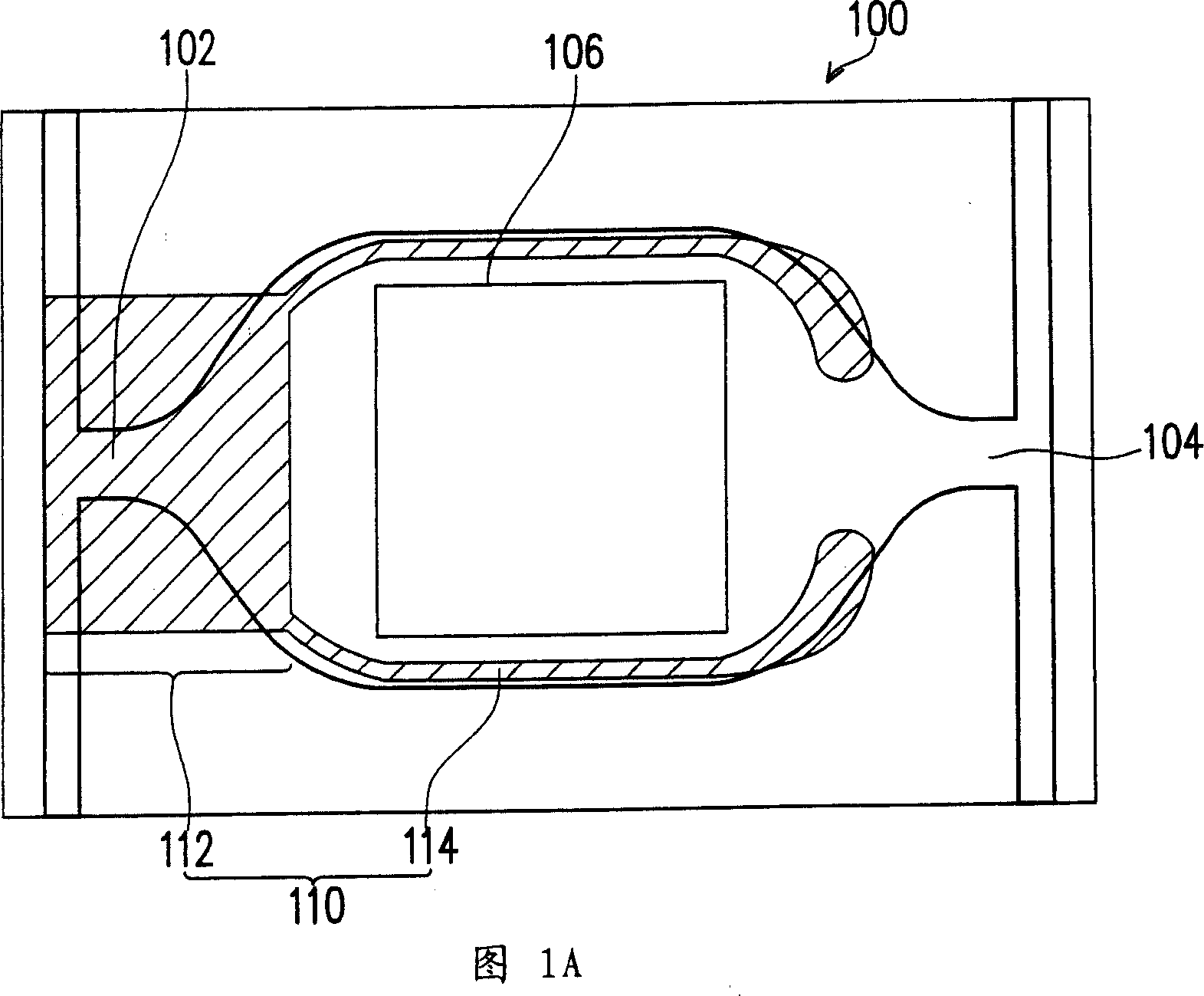

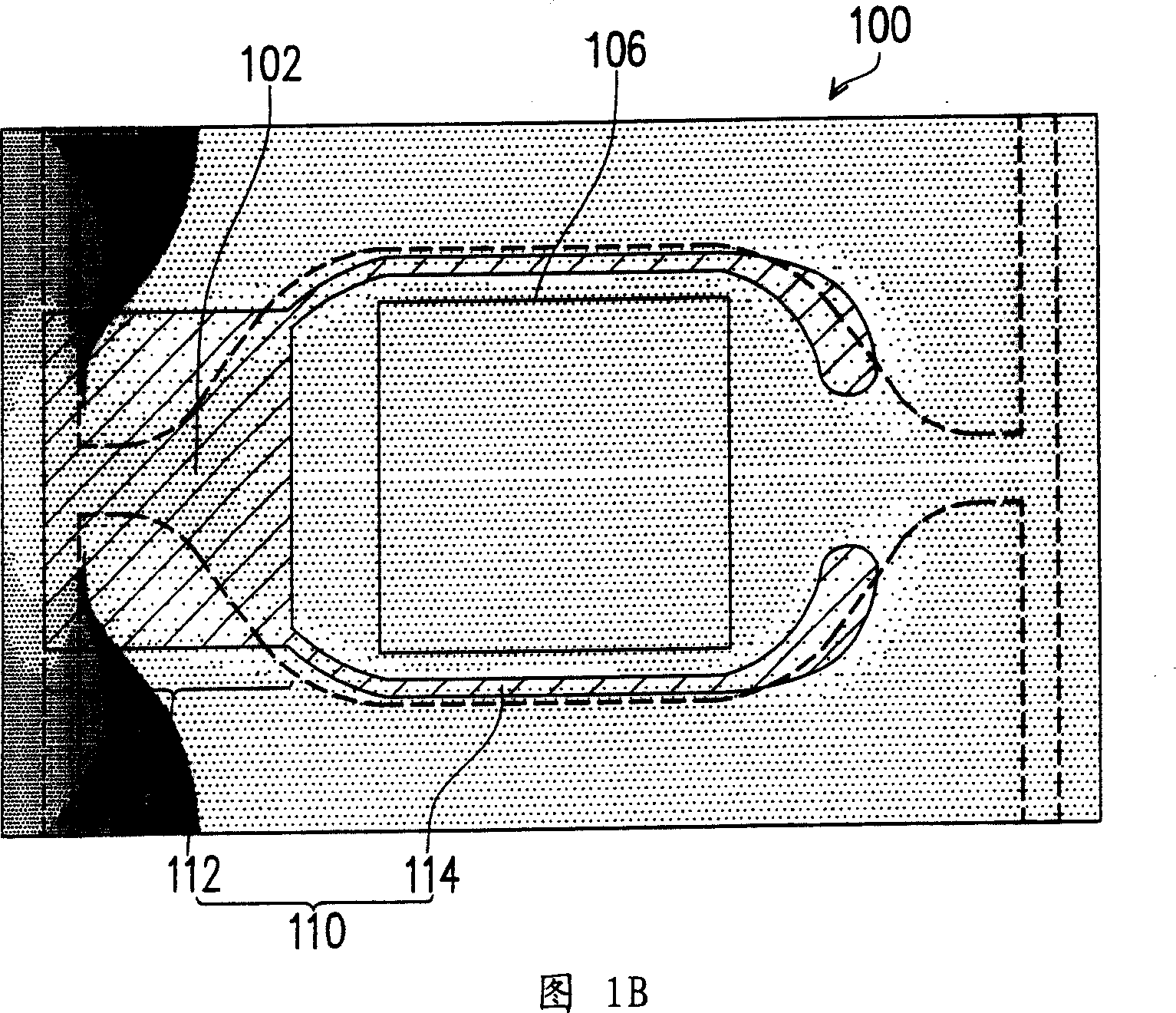

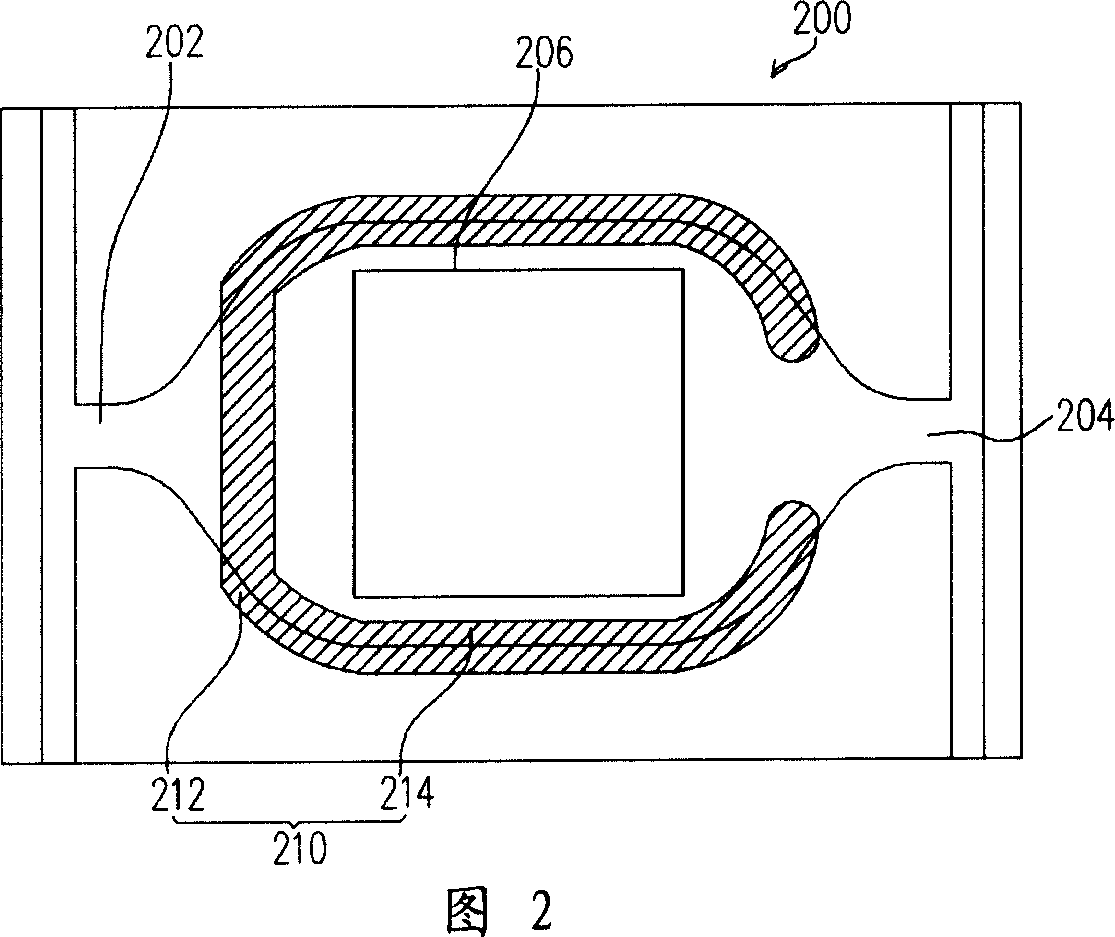

[0026] The micro-domain heating device of the present invention is used for heating microfluidic chips, and its design concept is to divide the whole micro-domain heating device into a preheating part and a heating part. Wherein, the preheating part corresponds to the fluid inlet of the aforementioned microfluidic chip, so that the temperature of the fluid is raised before entering the working area of the microfluidic chip. The heating part surrounds the working area of the microfluidic chip, so as to heat the fluid in the working area to a specific uniform temperature. Several embodiments are given below as examples, but it does not mean that the device of the present invention is limited to these embodiments.

[0027] FIG. 1A is a structural diagram of a microfluidic chip with a micro-domain heating device according to the first embodiment of the present invention.

[0028] Referring to FIG. 1A , there is a microfluidic chip 100 in this embodiment, and the microfluidic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com