Cross structure two-D wind speed wind direction sensor and its preparation method

A technology of wind speed, wind direction, and cross, which is applied to instruments, uses thermal variables to measure fluid speed, speed/acceleration/impact measurement, etc. It can solve problems such as unfavorable process and packaging, high power consumption of sensors, and fragile structure, etc., and achieve response time Long, improved sensitivity, simple and reliable process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

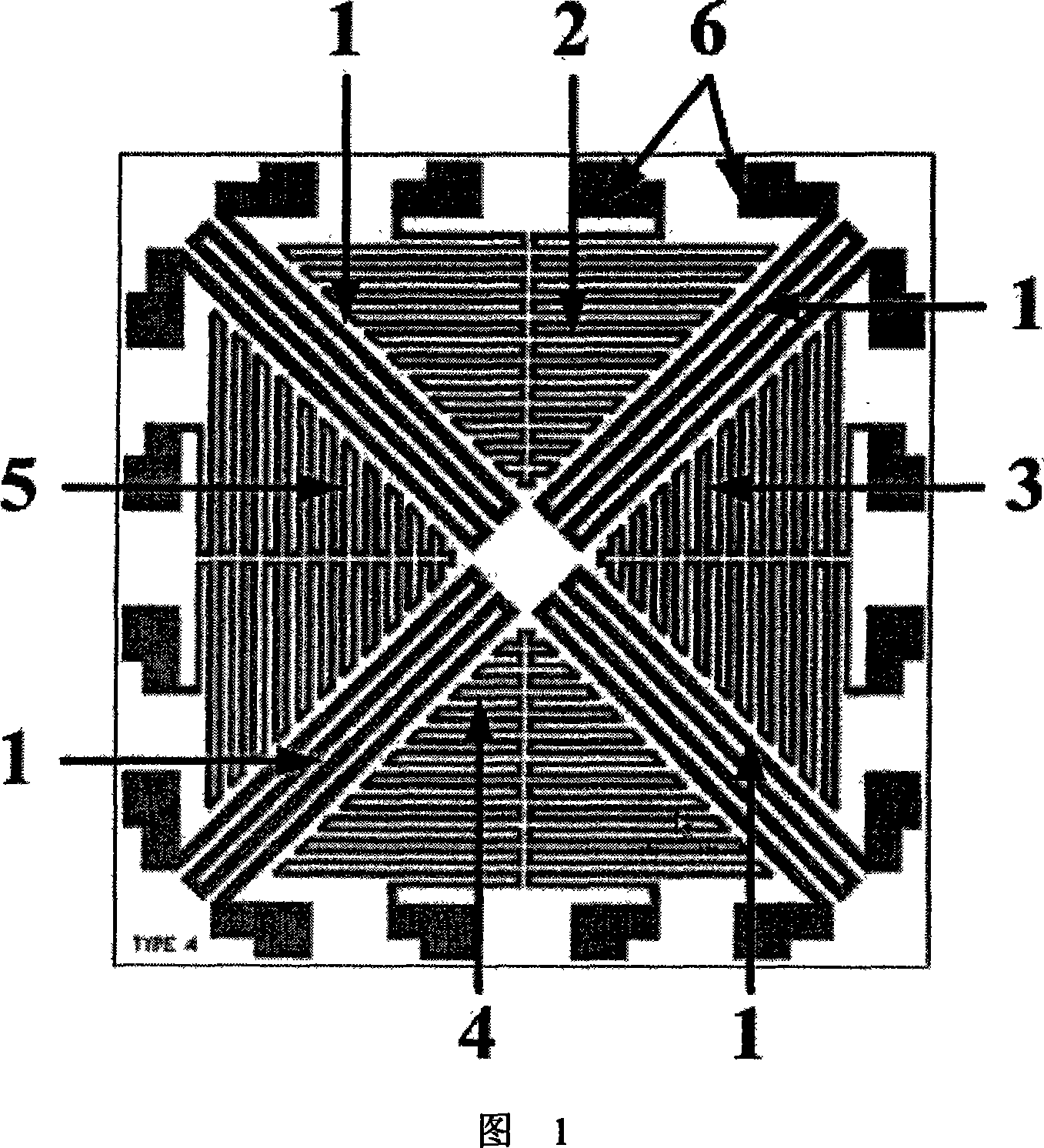

[0013] The invention is a two-dimensional wind speed and direction sensor with a cross structure. The sensor adopts a glass substrate, and on the glass substrate, there are a cross structure heating resistor 1, a first temperature measuring resistor 2, a second temperature measuring resistor 3, a third temperature measuring resistor 4, and a fourth temperature measuring resistor 5, which are respectively symmetrical Distributed between the heating resistors 1 of the cross structure; 16 pressure welding blocks symmetrically distributed around the glass substrate respectively lead out the heating resistors and the four temperature measuring resistors. The substrate is made of glass, ceramic or other materials with low thermal conductivity. The four temperature-measuring resistors are platinum, nickel or other metal resistors with high temperature coefficients made by lift-off process.

[0014] When the wind blows through the heating chip, the temperature field around the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com