Novel pavement material intensity tester

A pavement material and tester technology, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problems of low detection accuracy, low detection efficiency, large operation error, etc., and achieve good detection accuracy and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

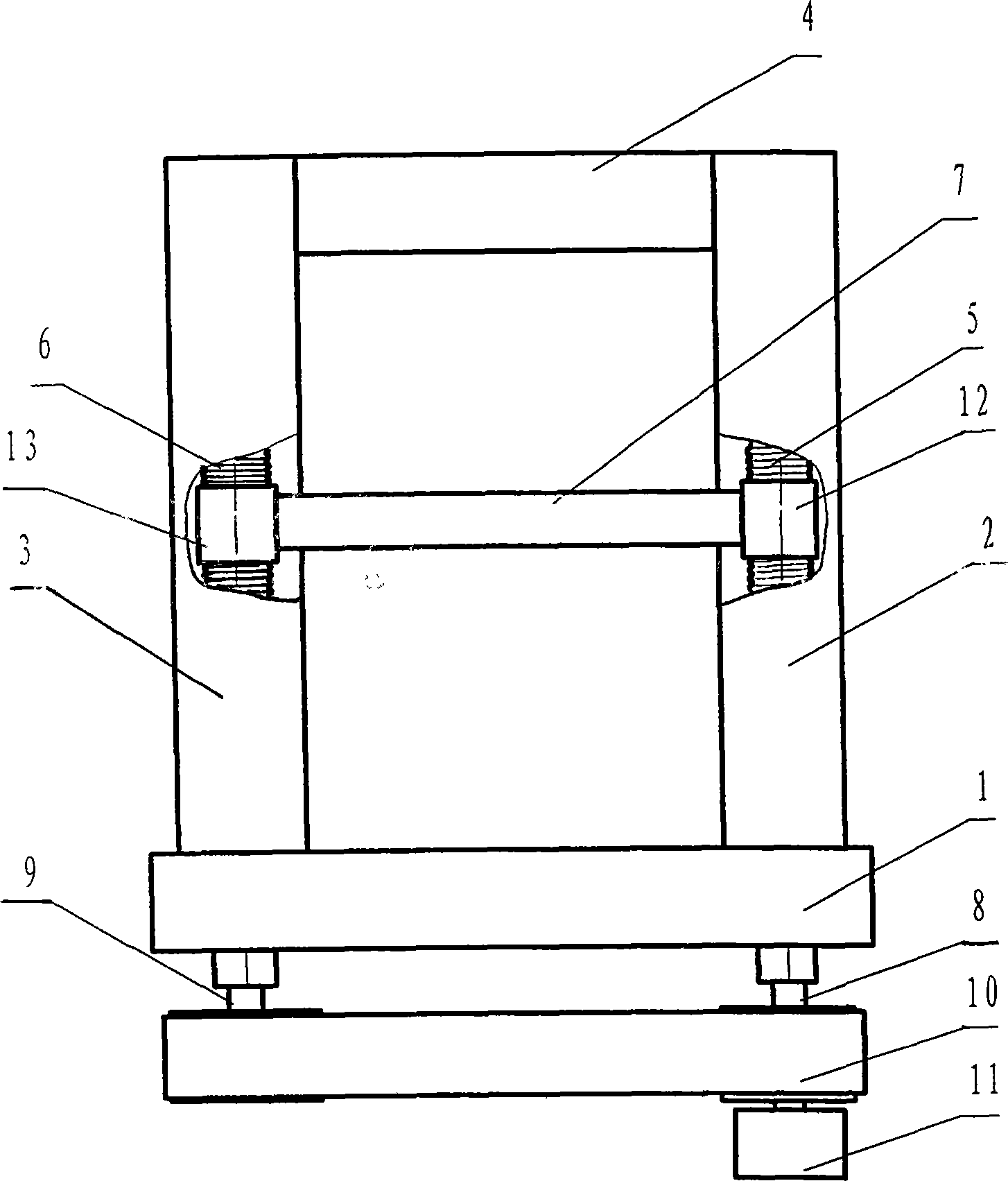

[0008] The present invention is described in detail below in conjunction with accompanying drawing:

[0009] The two sides of the transmission base 1 are respectively fixed column A2 and column B3, the top of the two columns is fixed with a beam 4, the inside of column A2 and column B3 is empty, and their inner surfaces are provided with wide grooves, and the screw rods in column A2 are respectively A5 and the screw B6 located in the column B3 pass through the base 1 and are fixedly connected with the synchronous gear under the base 1, the screw A5 is connected with the gear A8, the screw B6 is connected with the gear B9, and the gear A8 and the gear B9 are connected through a timing belt 10 , the gear B9 is connected to the rotating shaft of the servo motor 11, the transmission nut A12 and the transmission nut B13 are respectively sleeved on the screw rod A5 and the screw rod B6, the diameter, the helix angle and the pitch of the screw rod A5 and the screw rod B6 are the same,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com