Linear actuator

A linear drive, linear drive technology, applied in the direction of fluid pressure actuation device, servo motor, servo meter circuit, etc., to achieve the effect of kinematics design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

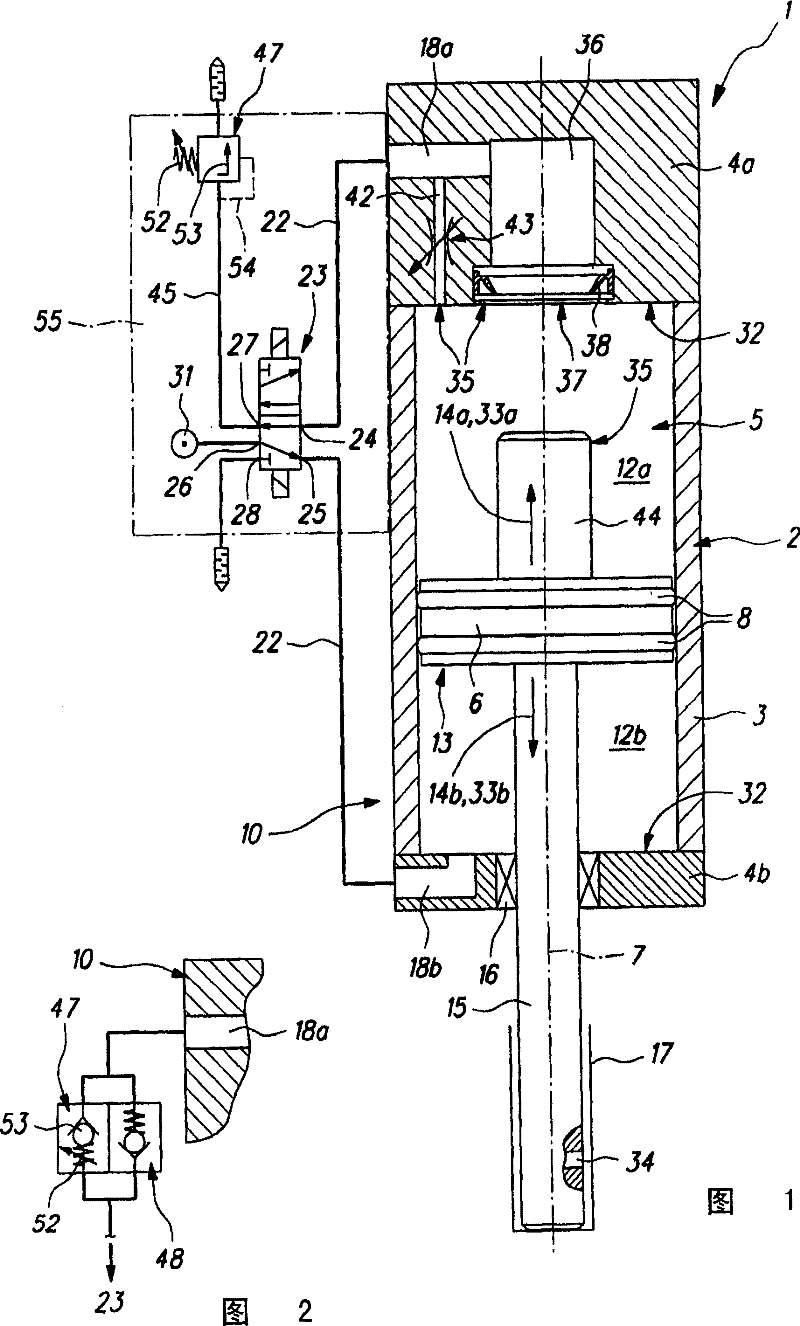

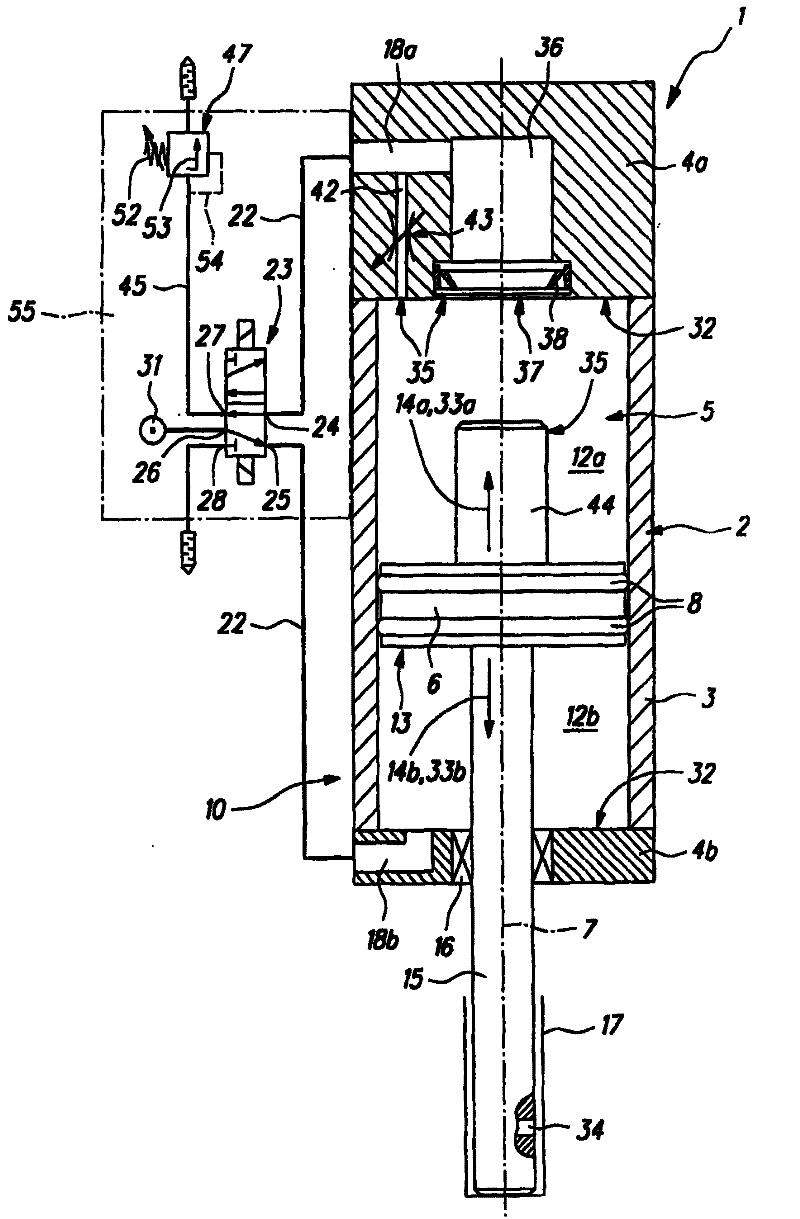

[0023] The linear drive generally designated 1 includes a pneumatic, ie compressed-air driven linear drive 10 , which is oriented vertically in the exemplary embodiment. However, the linear drive 10 can also be operated in other orientations.

[0024] The linear drive 10 comprises an elongated housing, referred to as the drive housing 2 , which consists, for example, of a housing tube 3 and two housing covers 4a, 4b arranged on its end faces. .

[0025] An elongated interior 5 is defined by the driver housing 2 , in which a driver piston 6 is accommodated displaceably in the longitudinal direction 7 of the driver housing 2 .

[0026] In the region of its outer circumference, the driver piston 6 has annular sealing means 8 which come into sealing contact with the peripheral walls of the inner space 5 so that the inner space 5 is divided into sealed portions by the driver piston 6 . Two axially successive working chambers 12a, 12b.

[0027] The drive piston 6 is part of a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com