Processing method, device and saccharification method for starch syrup raw material by extruding and adding enzyme

A technology for starch syrup and raw materials, applied in the field of processing starch sugar raw materials, can solve the problems of long time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation

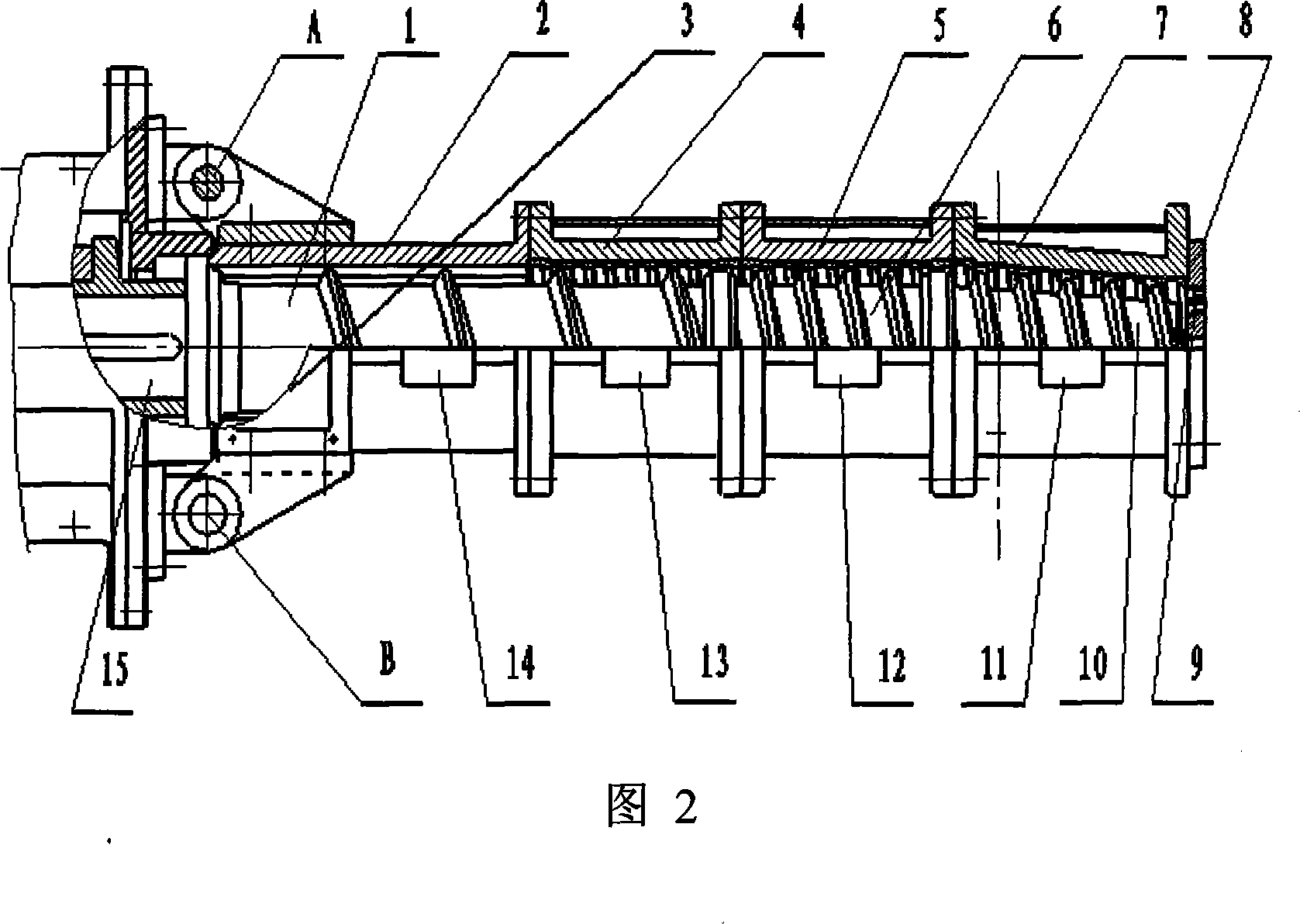

[0019] Embodiments of the present invention: the implementation of the present invention will be further described below in conjunction with the accompanying drawings. Accompanying drawing shows the extrusion cooking device of the starch syrup raw material that implements the extrusion cooking of the present invention and adds enzyme preparation. The first screw rod 1, the second screw rod 6 and the third screw rod 10 are sleeved on the main shaft 15 and rotate together. The speed is 30r / min-260r / min.

[0020] Among them, the starch syrup raw material before extrusion cooking is crushed and passed through a sieve with an aperture of 2-5mm, and the moisture content is adjusted to 20%-45%. At the same time, an appropriate amount of enzyme preparation is added to adjust the pH value to 4.2-7.2. The starch syrup raw material powder of the enzyme preparation enters the extrusion cooking device from the feeding port 3 (see the attached figure), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com