Roller of picking up ears to harvest corn

A technology for picking ear rollers and corn, which is applied to harvesters, agricultural machinery and implements, and applications. It can solve the problems of large damage to the roots of corn ears, large loss of corn ears, and decreased integrity rate of corn ears, etc., to improve the technology. Performance and level, practical design, reliable effect of pulling stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

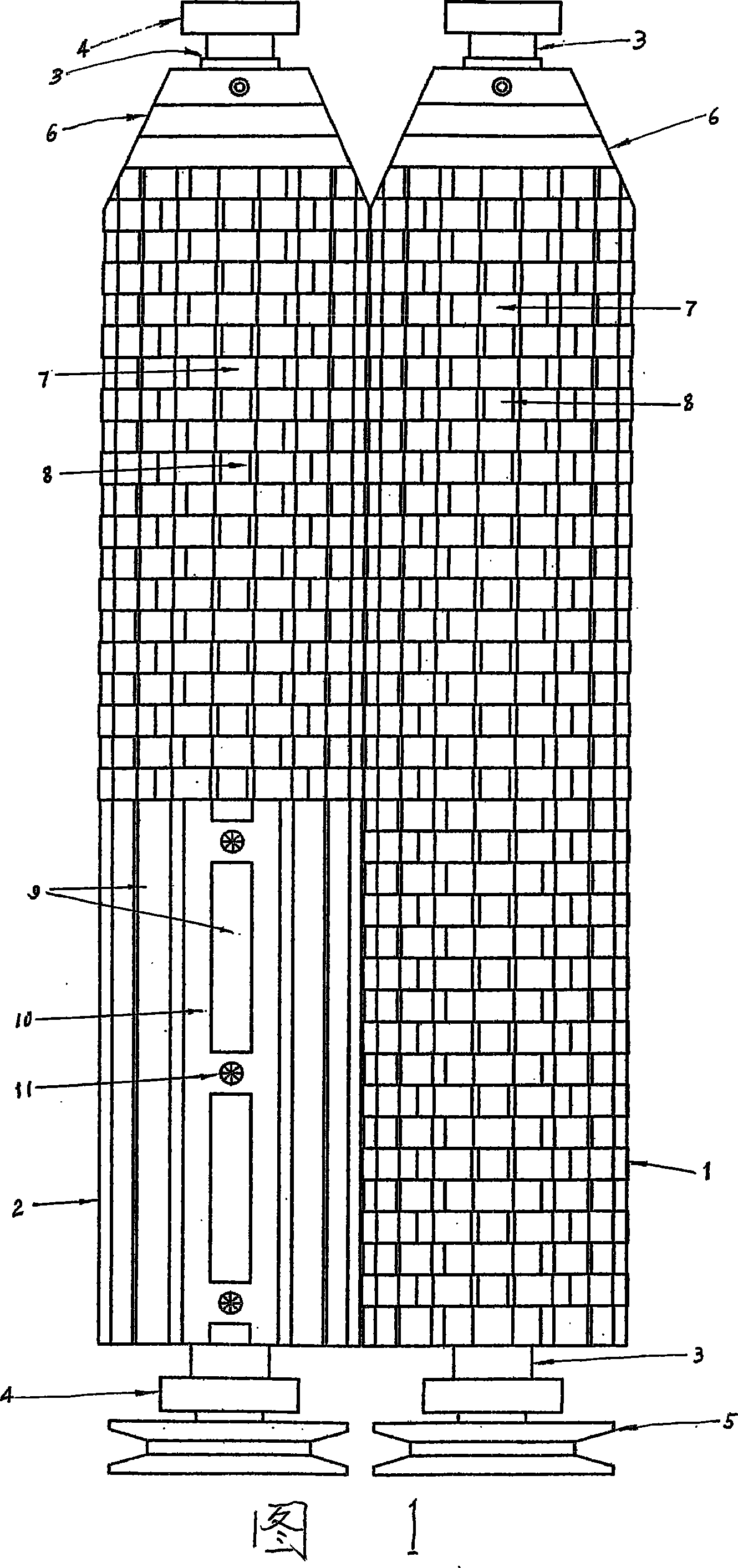

[0027] Example 1. Corn Harvesting Ear Picking Roller

[0028] The specific structure of the corn harvesting ear picking roller of this example is jointly shown by Fig. 1~Fig. The driving structure is such as a driven gear, or a tooth-chain, or a belt-wheel 5 structure, etc. The technical characteristics are: the corn harvesting and picking roller core 3 is made of metal, and the outer device of the core 3 is fixedly connected with a Flexible roller skin made of elastic flexible material. Each front end of all corn picking rollers 1 and 2 is slightly cone-shaped (as cone-shaped, pyramid-shaped, etc.) Body shape, etc.), this structure is beneficial for corn harvesting and stuttering into corn stalks. As shown in Fig. 1 and Fig. 2, its roll core 3 of the corn picking roller 1 is made of metal, and the outer device of the roll core 3 is fixedly connected with a flexible roll skin 6 made of elastic flexible material, such as various known and commonly used ones with elasticity T...

Embodiment 2

[0029] Embodiment 2. Corn harvesting ear picking roller

[0030]The general structure of the corn harvesting ear-picking roller of this example can be jointly shown by Fig. 2~Fig. Made of metal, the outer device of the roller core 3 is fixedly connected with a flexible roller skin 6 made of elastic flexible material, and the cylindrical surface (6) of the roller skin is evenly distributed with matrix-shaped protruding teeth 7 with n rows in the axial direction and m columns in the radial direction , where n is selected as a natural positive integer of 100≥n≥5, in this example, any odd or even number between 5 and 100 is selected for n. A pair of rollers of this example roller 1 structure just constitutes a pair of corn harvesting plucking ear rollers of each corn harvesting opening. Secondly, this pair of corn harvesting and ear-picking rollers 1 and 2 of this example can also form a pair of corn harvesting and ear-picking and peeling rollers. This corn harvesting and ear-pic...

Embodiment 3

[0031] Example 3. Corn Harvesting Ear Picking Roller

[0032] The general structure of the corn harvesting ear-picking roller of this example can be jointly shown in Fig. 2~Fig. The roll core 3 is made of metal, and the outer device of the roll core 3 is fixedly connected with a flexible roll skin 6 made of elastic flexible material. The roll skin cylindrical surface (6) is evenly distributed with matrix columns of n rows in the axial direction and m columns in the radial direction Shaped concave teeth 8, where n is selected as a natural positive integer of 100≥n≥5, in this example, any odd or even number between 5 and 100 is selected for n. A pair of rollers of this example roller 1 structure just constitutes a pair of corn harvesting plucking ear rollers of each corn harvesting opening. Secondly, this pair of corn ear picking rollers 1 and 2 of this example can also form a pair of corn harvesting ear picking and peeling rollers. Roller 2 is made into a pair, just can reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com