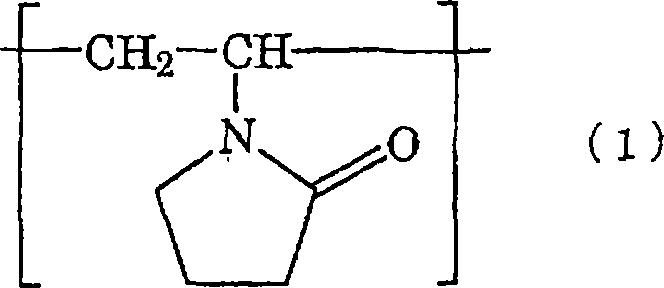

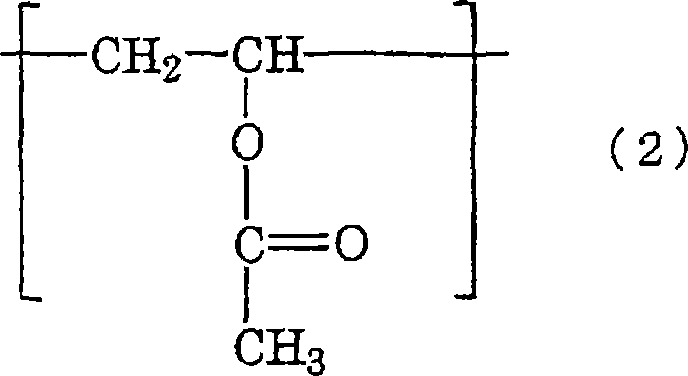

Vinylpyrrolidone/vinyl acetate copolymer, process for producing the same, and use of the same

A technology of vinylpyrrolidone and vinyl acetate, which is applied in the field of vinylpyrrolidone-vinyl acetate copolymer, and can solve problems such as easy turbidity and coloring, and difficulty in adoption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Add the mixed solvent of 40 parts of water / isopropanol (weight ratio)=5 / 5, 3 parts of N-vinylpyrrolidone and 3 parts of vinyl acetate in the reaction vessel that condensation pipe, nitrogen inlet pipe, thermometer are installed, stir Nitrogen gas is introduced at the same time to form a nitrogen atmosphere. Next, after heating with an oil bath so that the internal temperature of the reaction vessel reached 70° C., an initiator solution A was added, which was passed through a mixed solvent of 0.5 parts of water / isopropanol (weight ratio)=5 / 5. Formed by dissolving 0.03 parts of dimethyl-2,2'-azobisisobutyrate in Then, it took 4 hours to drop monomer solution A and initiator solution B respectively, wherein said monomer solution A contained 22.5 parts of N-vinylpyrrolidone and 17 parts of vinyl acetate, and said initiator solution B was passed through It is formed by dissolving 0.38 parts of dimethyl-2,2'-azobisisobutyrate in a mixed solvent of 7.2 parts of water / isopropa...

Embodiment 2

[0065] Except using the mixed solvent of water / isopropanol (weight ratio)=3 / 7 instead of the mixed solvent of water / isopropanol (weight ratio)=5 / 5 used in Example 1, operate in the same way as in Example 1 , carry out polymerization and distillation to obtain a colorless and transparent polymer solution with a concentration of 51.7% of vinylpyrrolidone / vinyl acetate copolymer. In addition, in distillation, residual N-vinylpyrrolidone / residual vinyl acetate (weight ratio) in the reaction liquid = 1.9 / 10 at the time when distilling off the solvent from the reaction liquid started. Moreover, at the moment of finishing the distillation (cooling moment), the concentration of N-vinylpyrrolidone in the reaction solution is reduced from 3720ppm before distillation to below 10ppm, and the concentration of vinyl acetate in the reaction solution is reduced from 19268ppm before distillation to below 50ppm. . And, the concentration of isopropanol is 0.1% or less.

[0066] The obtained po...

Embodiment 3

[0068] Add the mixed solvent of 40 parts of water / isopropanol (weight ratio)=5 / 5, 3.9 parts of N-vinylpyrrolidone and 2.6 parts of vinyl acetate to the polymerization vessel that condensation pipe, nitrogen gas introduction pipe, thermometer are installed, stir Nitrogen gas is introduced at the same time to form a nitrogen atmosphere. After heating with an oil bath to bring the internal temperature of the polymerization vessel to 70°C, add initiator solution A, which is obtained by dissolving 0.02 parts of dimethyl-2,2'-azobis in 0.5 parts of isopropanol formed from isobutyrate. Then, spend 4 hours to drop monomer solution A and initiator solution B respectively in this solution, wherein said monomer solution A contains 29.3 parts of N-vinylpyrrolidone and 23.5 parts of vinyl acetate, and said initiator solution B is formed by dissolving 0.25 parts of dimethyl-2,2'-azobisisobutyrate in 8 parts of isopropanol. After the dropwise addition, monomer solution B and initiator solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com