Golf clubs and golf club heads

A technology for golf clubs and club heads, which is applied to golf balls, golf clubs, rackets, etc., and can solve problems such as increasing the initial speed of the ball and flying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

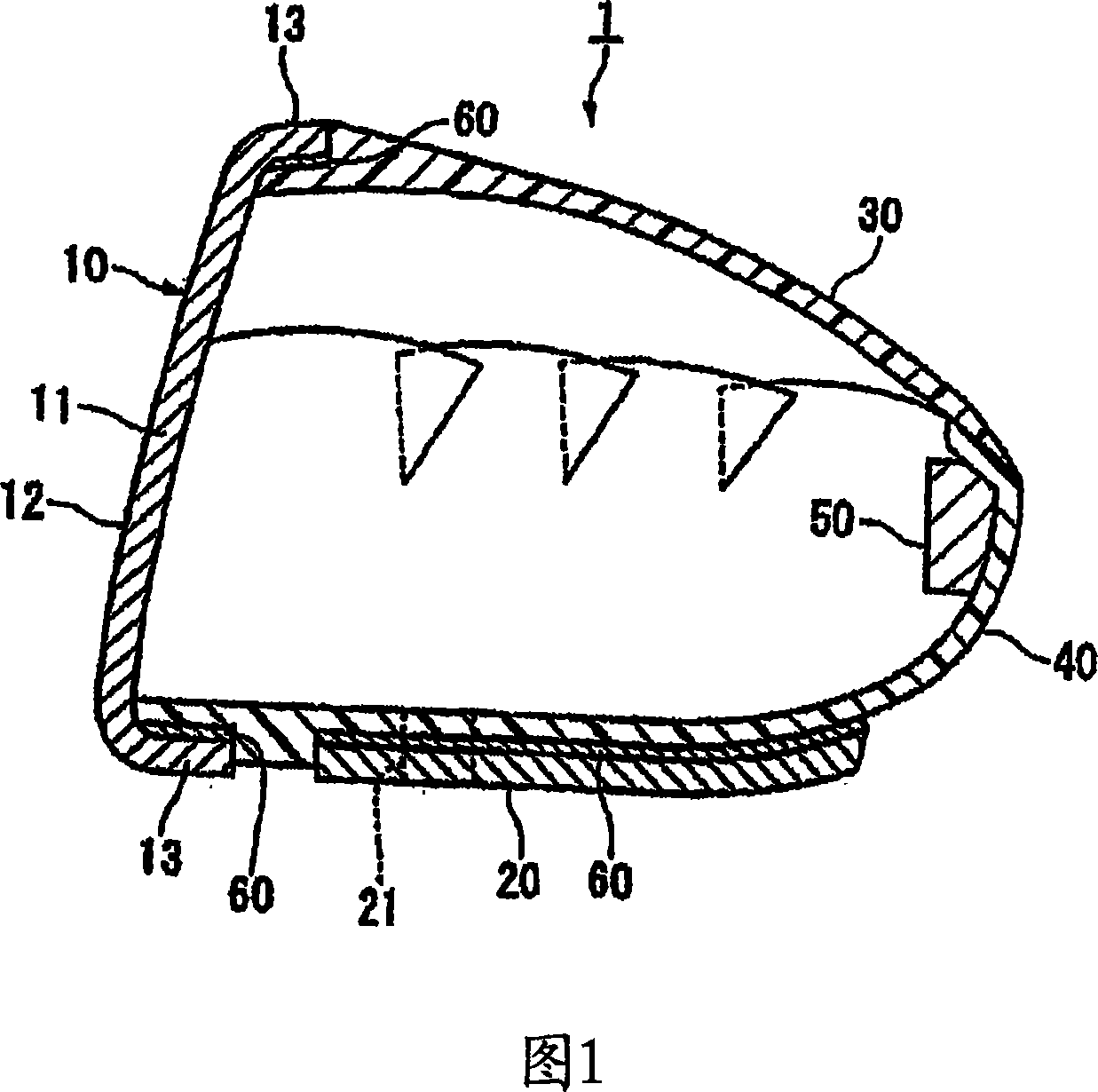

Embodiment 1

[0073] First, a titanium alloy panel having a face having a thickness of 2.8 mm and a flange having a thickness of 1.5 mm, and a base plate of stainless steel (SUS 314) having a thickness of 1.5 mm were respectively forged. Next, the flange surfaces of the face plate and the base plate were roughened by blast working, and then these surfaces were degreased using acetone.

[0074] Next, in the first preform manufacturing step, a prepreg having carbon fibers arranged in two intersecting directions (PYROFIL manufactured by Mitsubishi Rayon Co., Ltd.) is impregnated with epoxy resin. TR350), and first formed into the general configuration of the sole of a golf club head, thereby forming a first preform (thickness 1.5mm). At this time, hole portions are formed in the first preform so that the threaded holes on the bottom plate are not blocked by the bottom preform.

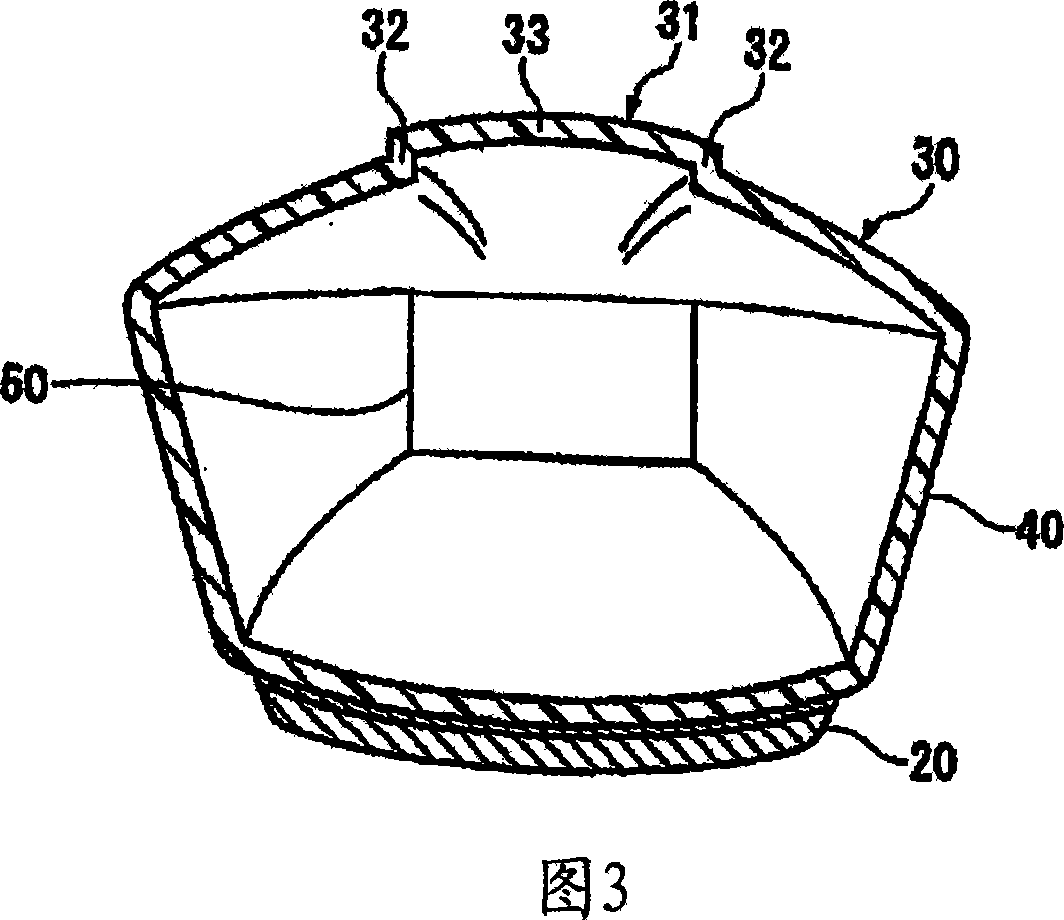

[0075]Next, in an assembly step, as shown in FIG. 4 , the bottom surface of the first preform 71 is bonded to the...

Embodiment 2

[0083] A golf club head was obtained in the same manner as in Example 1 except that grooves were not formed in the upper mold. The resulting golf club head was identical to the golf club head in Example 1 except that no raised portion was provided.

Embodiment 3

[0085] A golf club head was obtained in the same manner as in Example 2, except that a second preform was formed by laminating prepregs such that the direction of carbon fibers thereof alternated between 0° and 90° with respect to the ball striking face.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com