Pumping unit

A technology of pumping units and sucker rods, which is applied to mechanical equipment, mining fluids, boreholes/well components, etc., can solve the problems of small output power and waste of motor power, and achieve the effect of reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

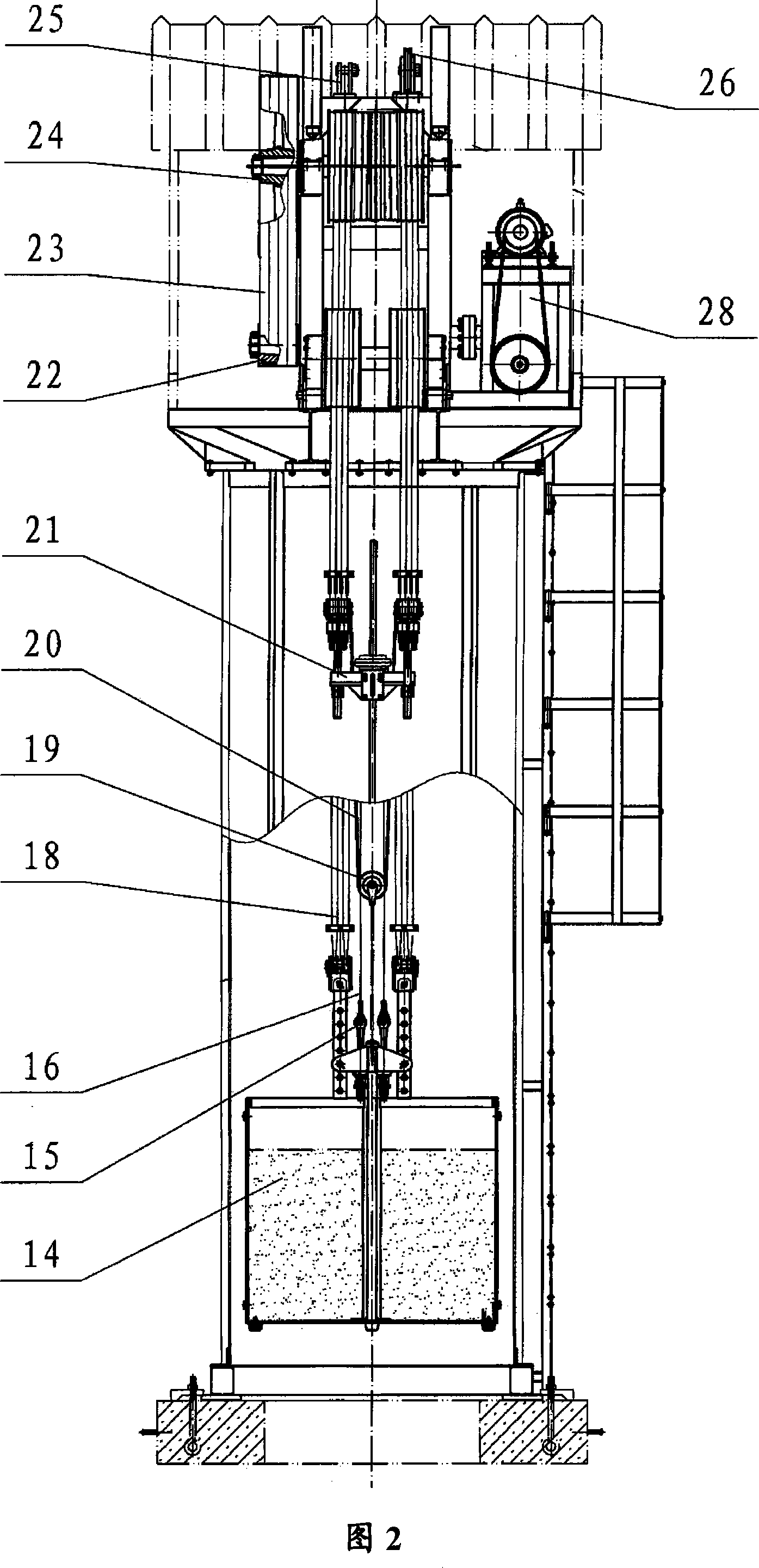

[0023] Below, the pumping unit provided by the present invention will be further described in conjunction with the accompanying drawings, but the present invention is not limited thereto.

[0024] As shown in Figures 1, 2, and 3, in one embodiment of the present invention, a pumping unit is provided, which includes a main frame 1, a bracket 8, a motor 10, a brake 11, a control device 9, an oil pumping Bar 4, rope hanger 21, counterweight 14, drive shaft 30, drive rope 18, drive wheel 29, winch machine 28 and winch rope 20 and transmission device. Wherein, the top of the main frame 1 has a support 8, the support 8 has a platform, the drive shaft 30 is installed on the support 8, the drive wheel 29 is installed on the drive shaft 30, the sucker rod 4 and the rope hanger 21 is connected with counterweight 14 by drive rope 18 that goes around drive wheel 29.

[0025] In the invention, the control device can be in the form of an electric control cabinet 9, in which electrical comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com