Technology for coarse bromine purifying using hydrobomic acid enriched liquid

A technology of enrichment solution and hydrobromic acid, which is applied in the direction of bromine/hydrogen bromide, can solve environmental pollution and other problems, and achieve the effects of solving environmental pollution problems, saving usage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

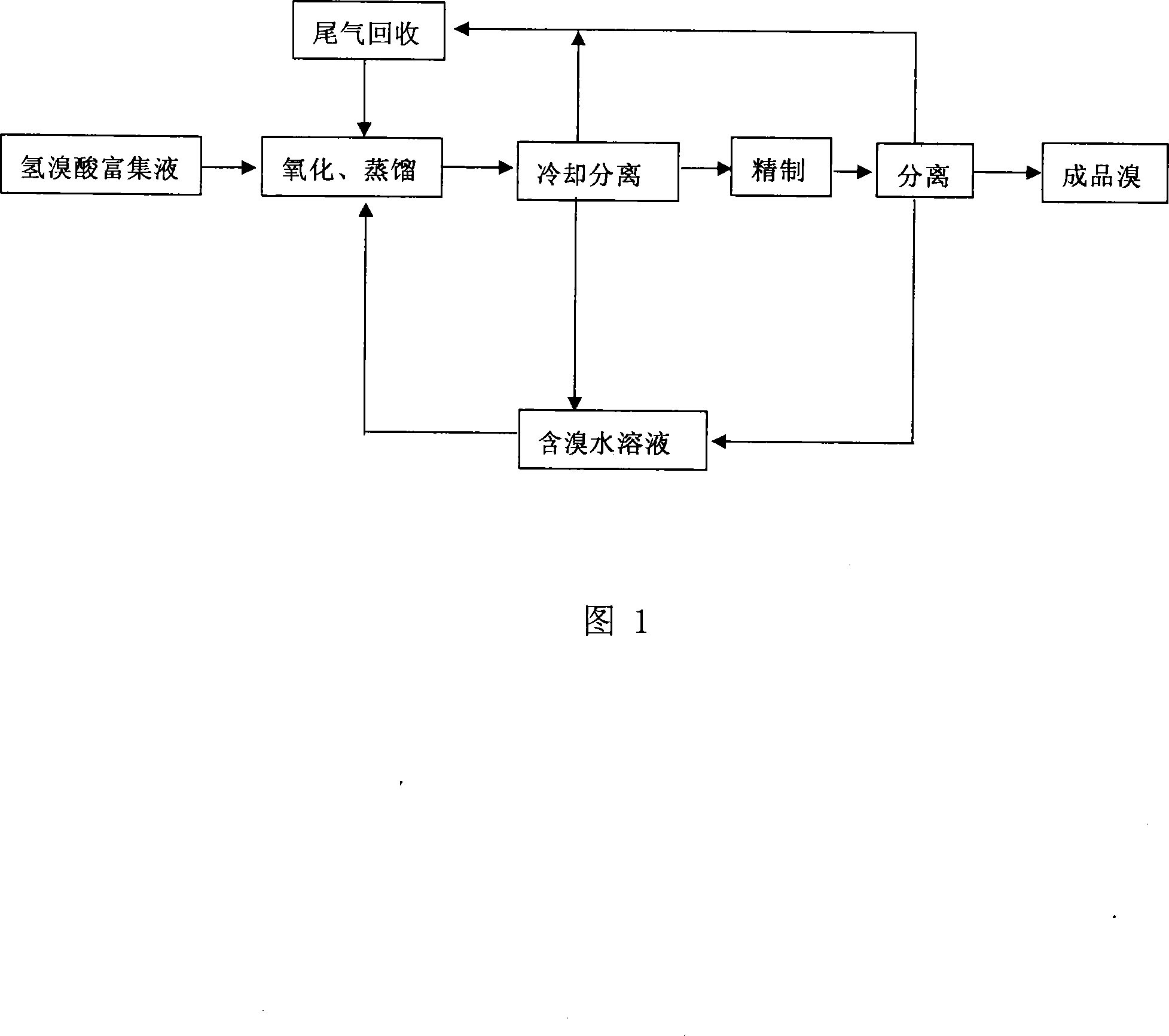

[0012] The process of purifying crude bromine by using hydrobromic acid enrichment solution of the present invention will be described in conjunction with the accompanying drawings and examples.

[0013] As shown in Figure 1, the process of utilizing hydrobromic acid enrichment solution of the present invention to carry out crude bromine purification, its process steps are realized in this way.

[0014] Step 1, oxidative distillation, import the hydrobromic acid enriched liquid into the distillation tower, feed a certain amount of chlorine gas, the chlorine distribution rate is 100% to 110%, that is, the ratio of the chlorine gas quality and the bromine quality in the raw material is the distribution ratio. chlorine rate. At the same time, steam is introduced so that the top temperature of the distillation tower is 50°C to 80°C, the hydrobromic acid enriched liquid is oxidized, and after distillation, cooling, and separation, crude bromine and bromine-containing aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com