Structure of peltier element or seebeck element and its manufacturing method

A manufacturing method and Seebeck coefficient technology, which are applied in the manufacture/processing of thermoelectric devices, junction lead-out materials of thermoelectric devices, thermoelectric devices using only Peltier or Seebeck effect, etc. Reduced utilization efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

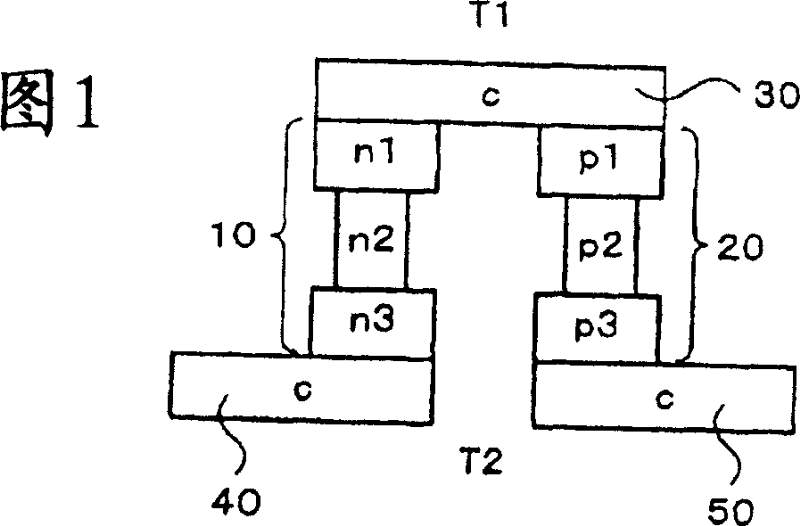

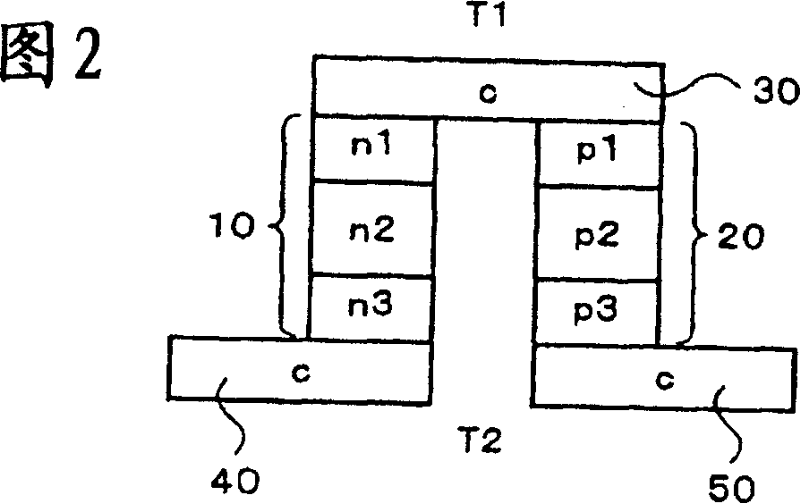

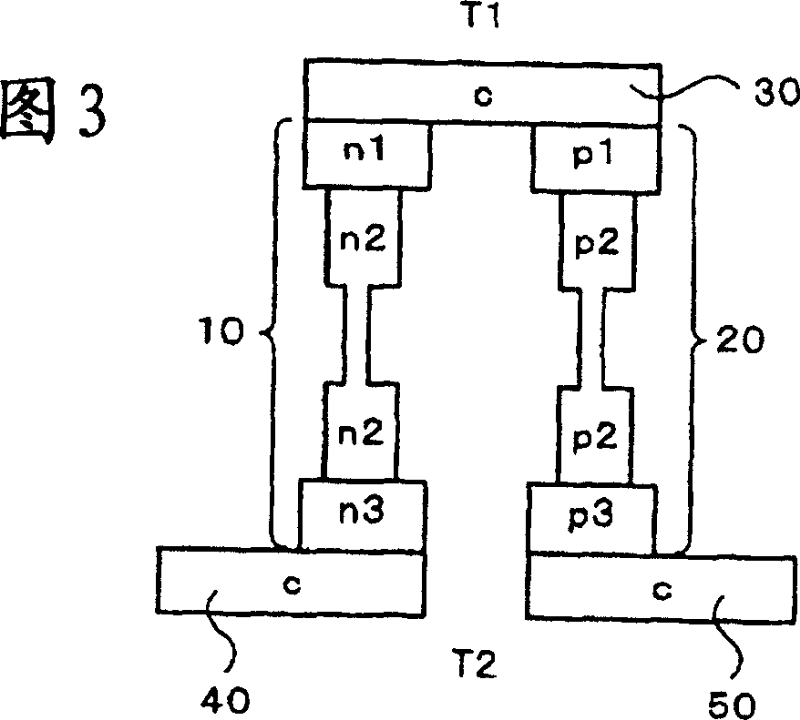

[0066] Hereinafter, the structure and manufacturing method of the Peltier element or Seebeck element of the present invention will be described with reference to the drawings. FIG. 1 is a schematic configuration diagram of a Peltier element or a Seebeck element according to a first embodiment of the present invention.

[0067] As shown in FIG. 1 , a first conductive member (n-type semiconductor, etc.) 10 having a predetermined Seebeck coefficient includes two end portions n1 and n3 and a middle portion n2. In addition, the second conductive member (p-type semiconductor, etc.) 20 having a Seebeck coefficient different from that of the first conductive member includes two end portions p1 and p2 and an intermediate portion p2.

[0068] The middle portions n2 and p2 of the first conductive member 10 and the second conductive member 20 have a cross section smaller than that of the two end portions n1, n3, p1, p3. Therefore, the thermal conductivity of the middle portion becomes sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com