High-pressure resistant hose and manufacturing method thereof

A high-pressure, hose-resistant technology, applied in the direction of hoses, hose connection devices, pipes, etc., can solve problems such as troublesome post-processing, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

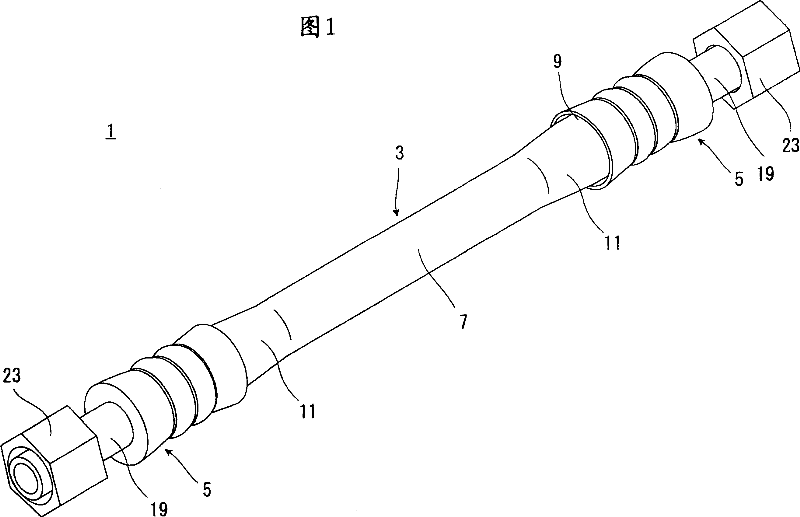

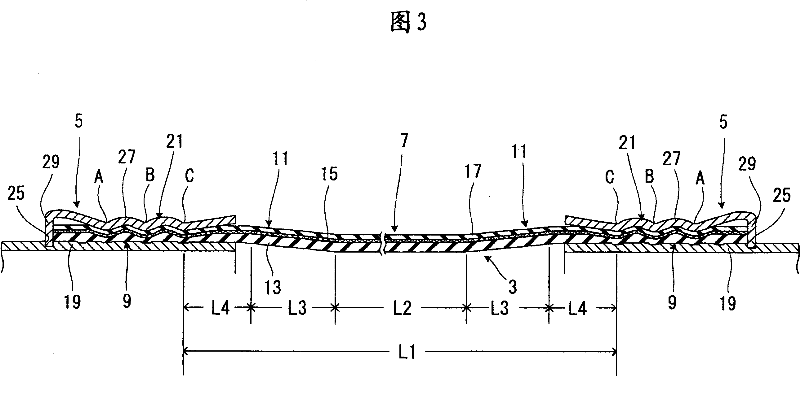

[0042]The high-pressure hose 1 in FIG. 1 is used, for example, as an air-conditioning hose of a motor vehicle. The anti-high pressure hose 1 comprises a hose body 3 to which metal joint fittings (couplings or joints) 5 are securely fitted to two axially opposite ends of the hose body. The hose main body 3 has a main portion 7 located at its axially central portion, swaged portions or portions to be swaged (tightened portions) 9, 9 located at its axially opposite ends, and portions located at the main portions 7 and swaged The tapered portion 11, 11 between the forged portion 9. The main portion 7 is formed in an elongated tubular shape and has the same inner and outer diameters throughout its length. Each swaged portion 9 has a tubular shape with an inner diameter and an outer diameter larger than those of the main portion 7 . Each tapered portion 11 is tapered with a diameter decreasing from said swaged portion 9 to said main portion 7 .

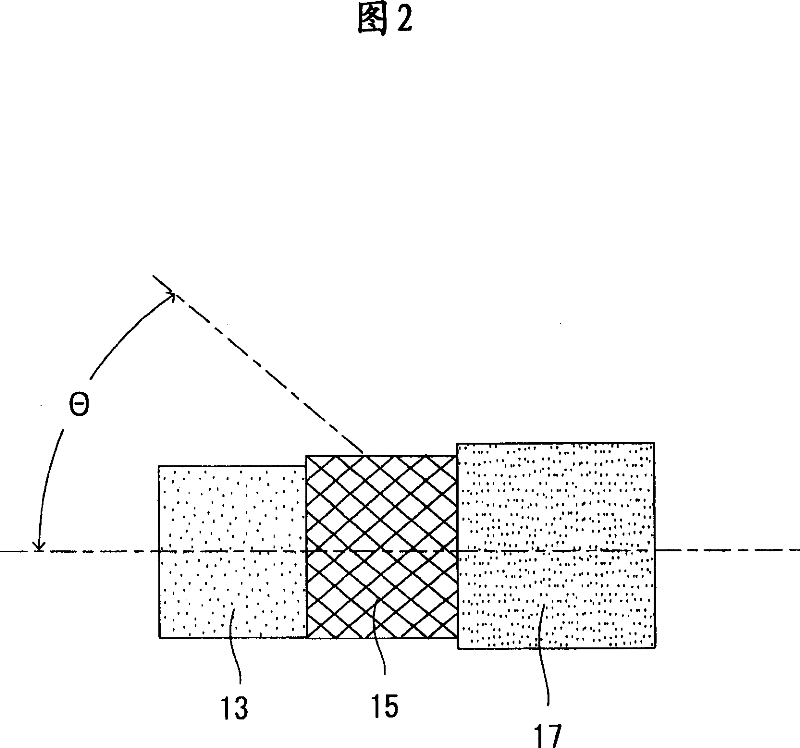

[0043] As shown in FIG. 2 , the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com