T-shaped pipework element for an auxiliary circuit of a nuclear reactor, connection piece and method for producing and assembling the pipework element

A technology for nuclear reactors and tube components, applied in the direction of nuclear reactor monitoring, reactors, nuclear power plant auxiliary equipment, etc., can solve problems that have not been considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

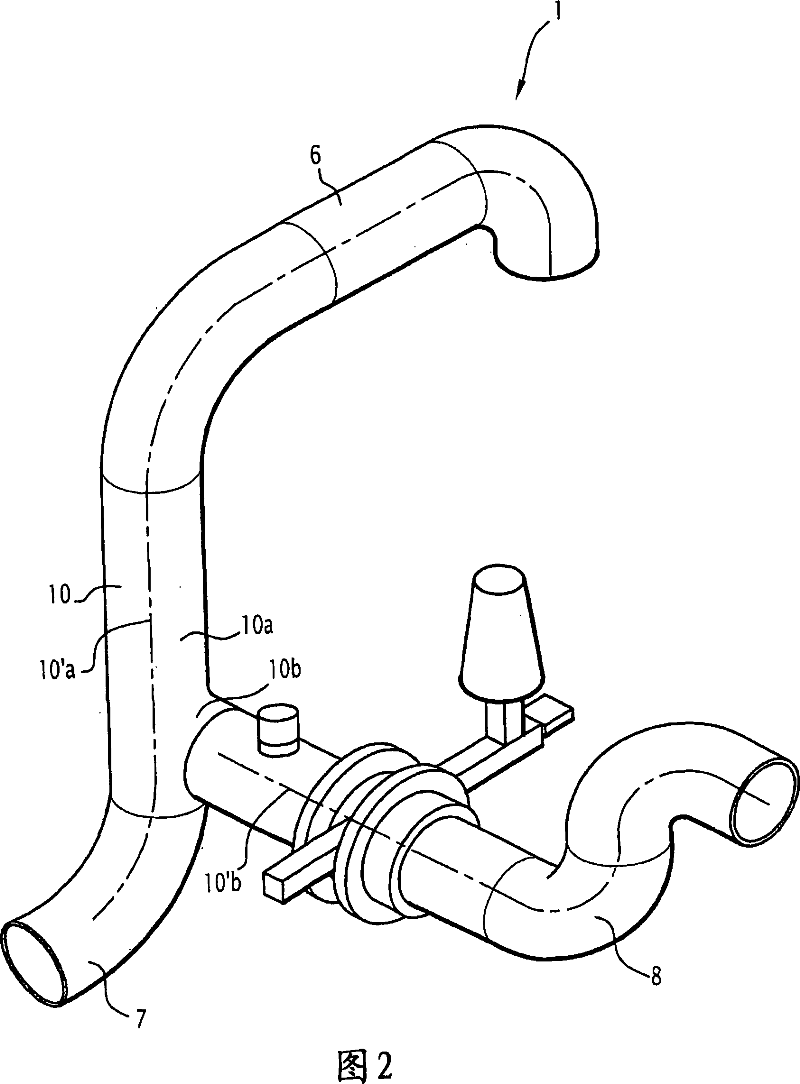

[0042] [42] FIG. 1 schematically shows a shutdown RRA cooling circuit of a pressurized water nuclear reactor, which circuit is connected to the main circuit 14 of the nuclear reactor, and the pressurized water constituting the primary cooling fluid of the nuclear reactor flows in the main circuit 14 .

[0043] [43] The main loop 14 of the nuclear reactor includes several loops, and there is a main pump and a steam generator in each loop to make the first fluid flow, and the pressure vessel of the nuclear reactor is connected with the pump and the steam generator. The core is located in the pressure vessel of the reactor. The main loop of a pressurized water nuclear reactor generally includes three or four loops.

[0044] [44] The circuit RRA1 shown in Fig. 1 is connected with two hot branches of the main circuit 14, that is, two heated main waters guaranteed to be in contact with the core are transferred to a steam generator through the extraction lines 2a, 2b, and some cut-of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com