Annular concentrically twisted bead cord

A bead, annular technology, applied in the direction of the bead, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problem of the impracticality of the annular core, achieve weight and low cost, easy to remove burrs, weldability and heat resistance high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

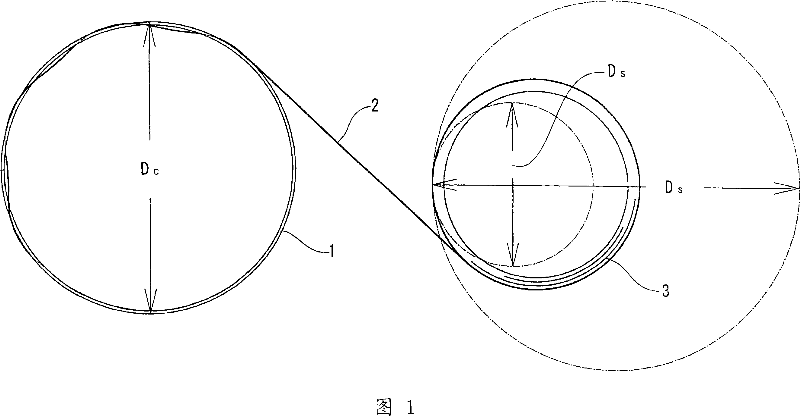

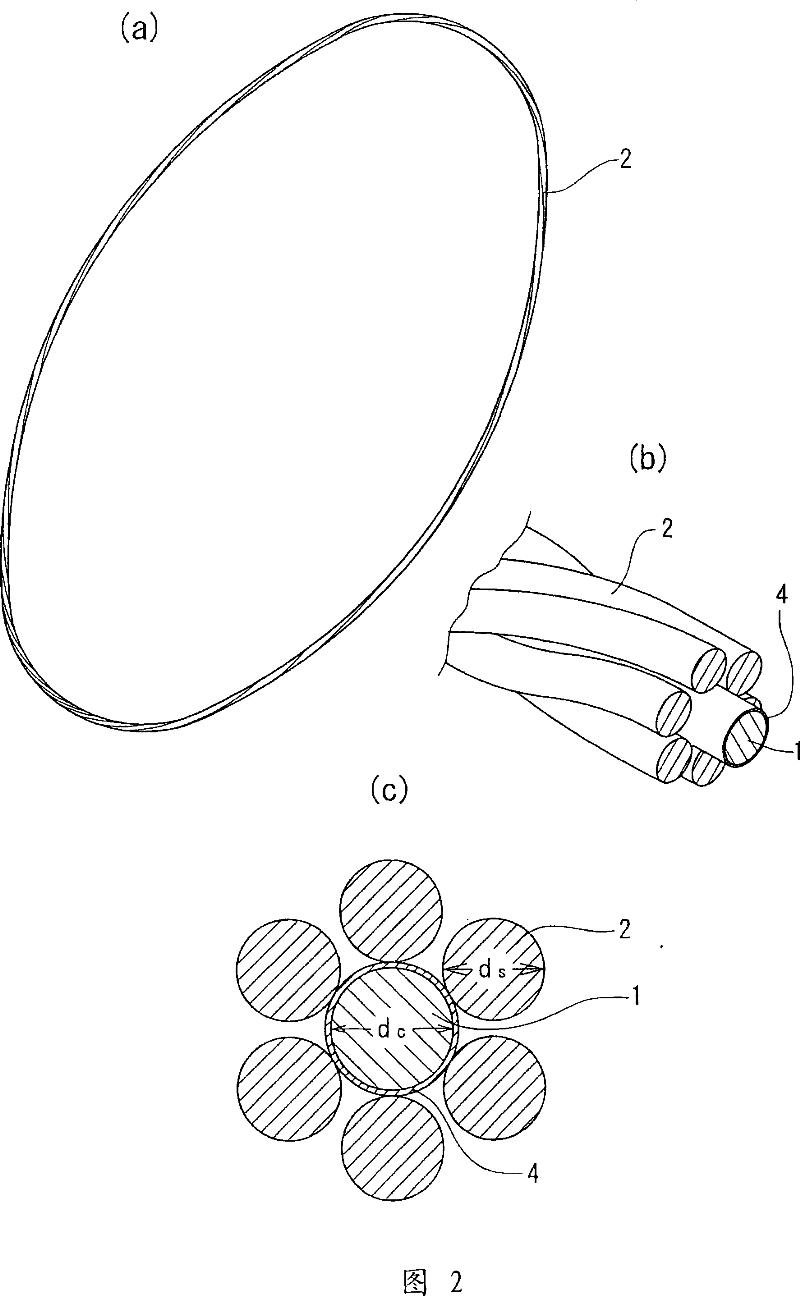

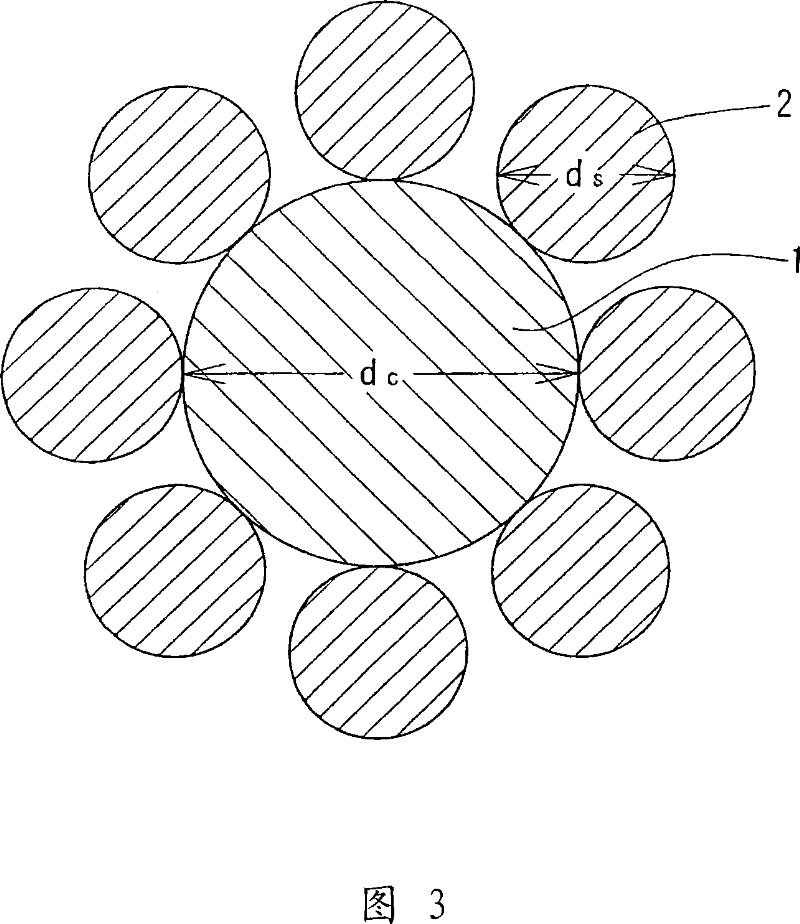

[0049] The embodiments of the present invention will now be described with reference to the drawings. As shown in Figures 1 and 2(a)-2(c), the annular concentric bead cord of this embodiment has a wire coil diameter of D C The diameter of the annular core 1 and the wire coil is D S The covered wire 2 is supplied from the covered wire supply tray 3 and spirally wound on the annular core 1. In this embodiment, as shown in Figures 2(b) and 2(c), the diameter is d S The covered wire 2 is wound with a diameter of d C A single sheath is formed by forming 6 circles along the ring core of the ring core. However, the covered wire can also be wound on the annular core to form multiple sheaths.

[0050] The two ends of the steel wire are welded together to form an annular core, where the diameter of the steel wire is slightly larger than the diameter of the covered wire 2 (proportion (d C / d S ) = 1.04 to 1.30) and made of medium carbon steel with a carbon content of 0.28 to 0.56 by weight. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com