Hoisting method of folding straddle truck and device thereof

A hoisting method and gantry crane technology, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as increasing labor intensity of workers, increasing unsafe factors, increasing diesel engine power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

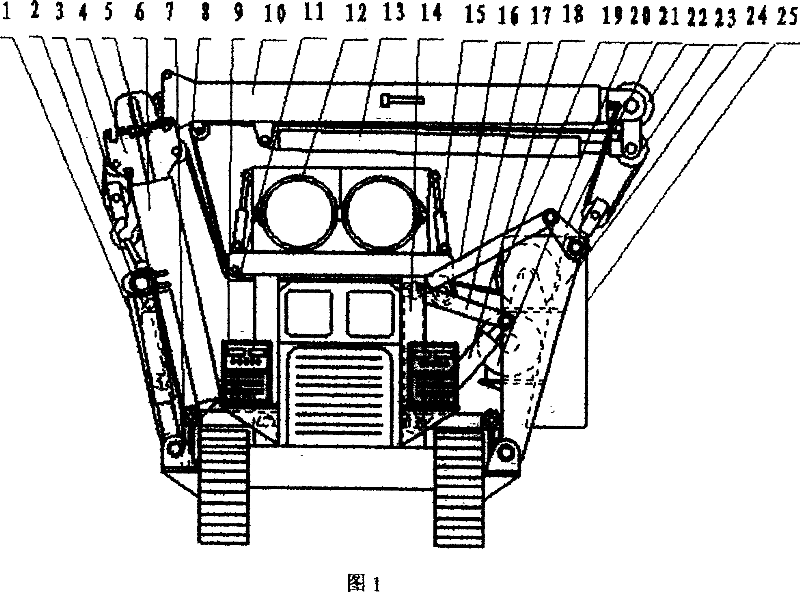

[0025] The following examples illustrate the folding gantry crane hoisting method and arc welding car of the present invention.

[0026] The folding gantry crane hoisting method of the present invention comprises:

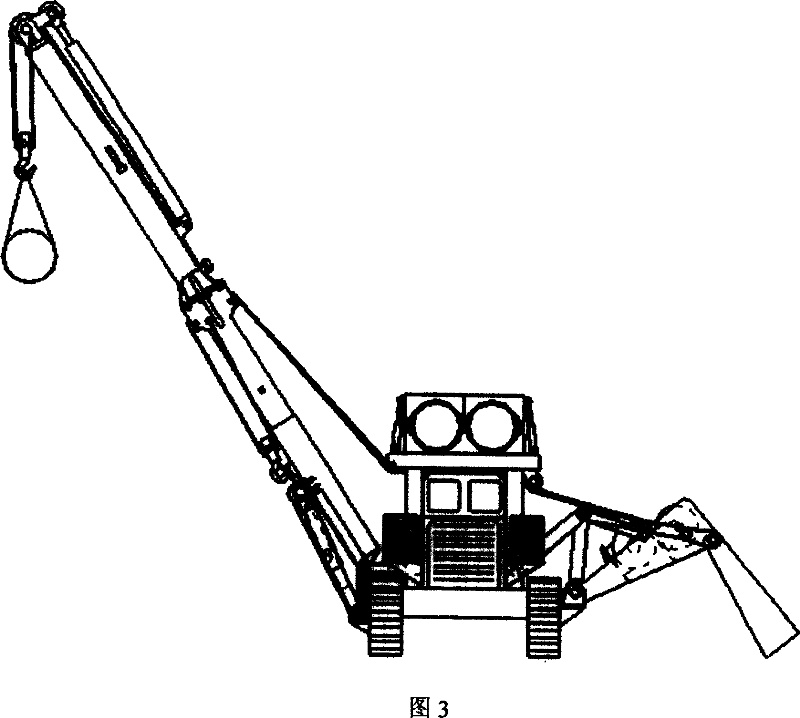

[0027] a. Operate the hydraulic arm of the boom so that the angle between the main boom and the ground is greater than 80 degrees;

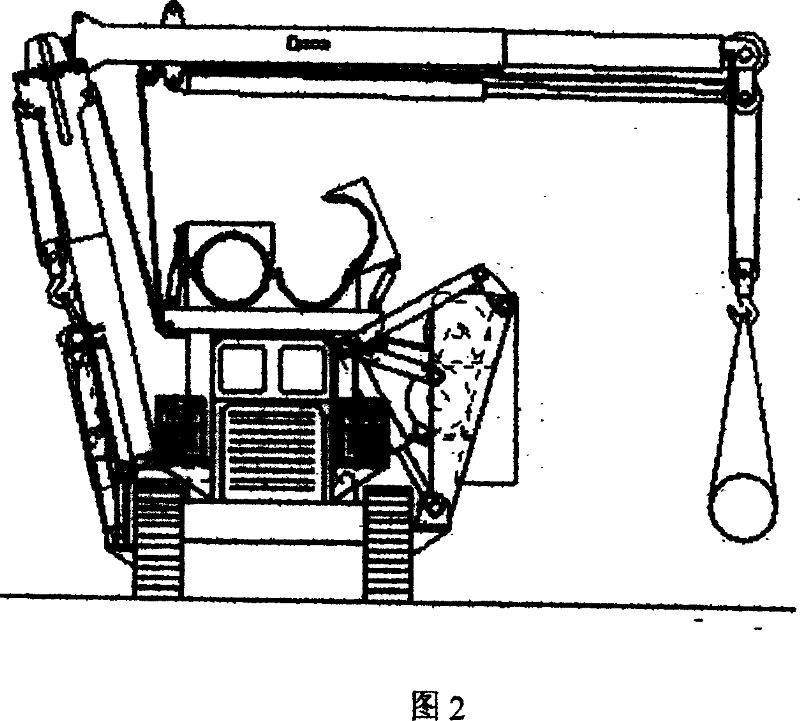

[0028] b. Operate the outrigger hydraulic cylinder and folding hydraulic cylinder so that the angle between the main boom and the auxiliary boom is 60 degrees;

[0029] c. Operate the main hydraulic winch to put down the main hook, and hang the lifting pipe on the main hook;

[0030] d. Operate the main hydraulic winch to lift the pipeline to a certain height;

[0031] e. Operate the hydraulic support feet of the lifting arm to support the ground, and change the lifting support point;

[0032] f. Operate the hydraulic arm of the lifting arm and retract the hydraulic support feet of the lifting arm to make the main boom rotate;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com