Non-woven guidance device and textile manufacturing machine

A technology of non-woven fabrics and guiding devices, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as difficulty in application and limited possibilities, and achieve the effect of compact design, suitable structure and control advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

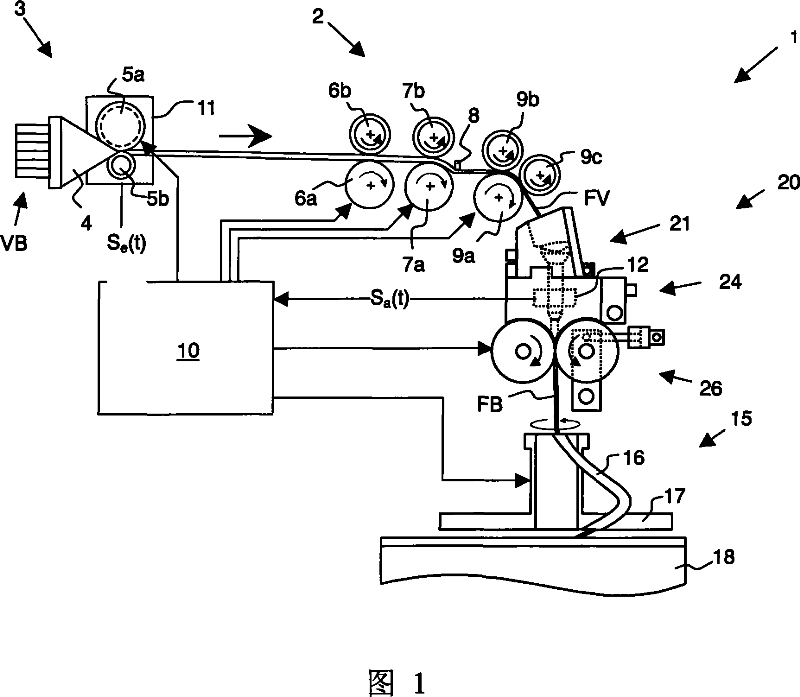

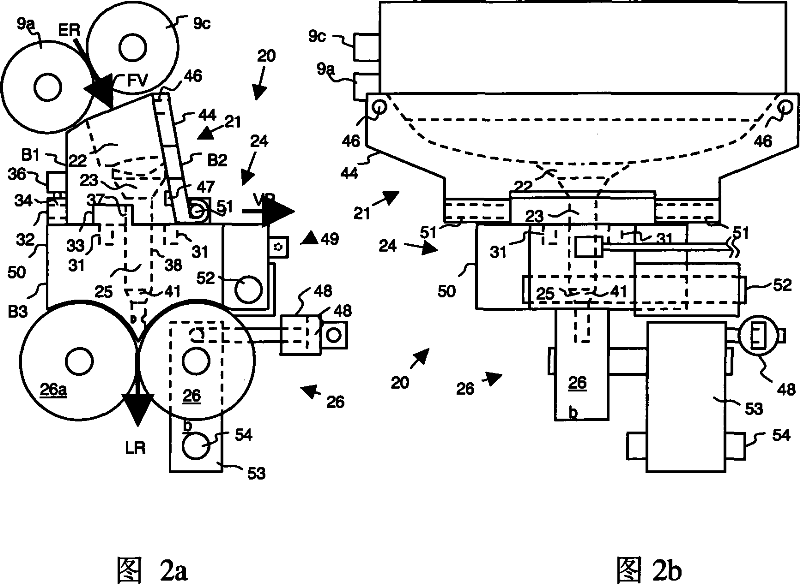

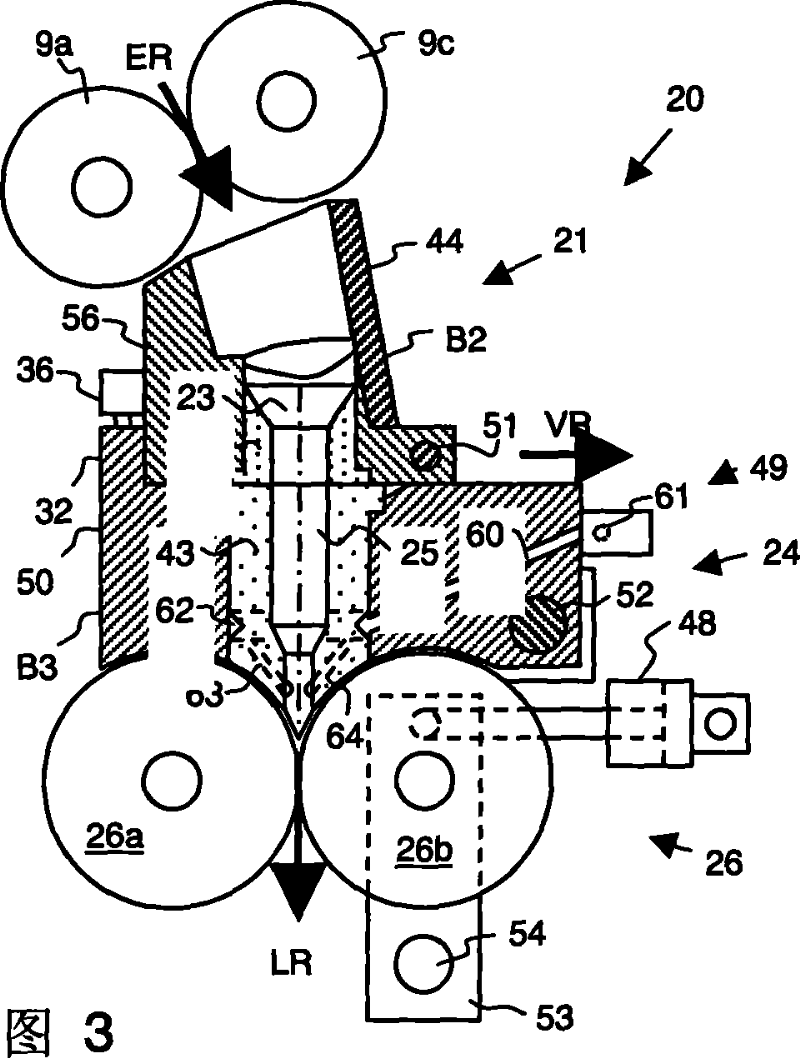

[0075] Fig. 1 shows a draw frame 1, which is an example of a textile machine 1, which has a drafting device 2, which outputs a diffused fiber nonwoven FV. However, the present invention relates to other textile machines 1, in particular spinning preparation machines 1, for example, cards or combers, all having a drafting device 2 or other device 2, the output of diffused fibers is not Fabric FV.

[0076] The task of the draw frame 1 is to combine, mix, draft, parallelize or regularize one or more feed slivers from the card, comber or previous drawframe. However, when carrying out, a high-quality sliver produced by high-speed operation should not be difficult to implement on the draw frame 1.

[0077] The schematic diagram represents a draw frame 1 with a guide area 3, for example, 6 individual feed bars VB fed one after the other. The guide area 3 and the feed bar VB are seen from above, while the draw frame 1 is only seen from the side.

[0078] In the guide area 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com