Wax block for hot air blastoff lamp

A hot gas and wax block technology, applied in the production of candles and fatty acids, etc., can solve the problems of unsafe transportation or storage, difficult control by people, safety accidents, etc., and achieve the effect of simple ignition operation, increased strength, and less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

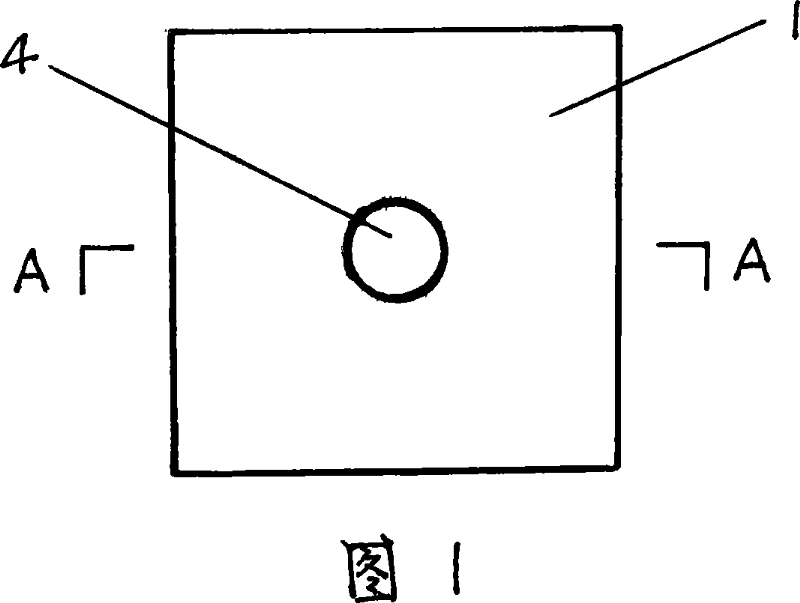

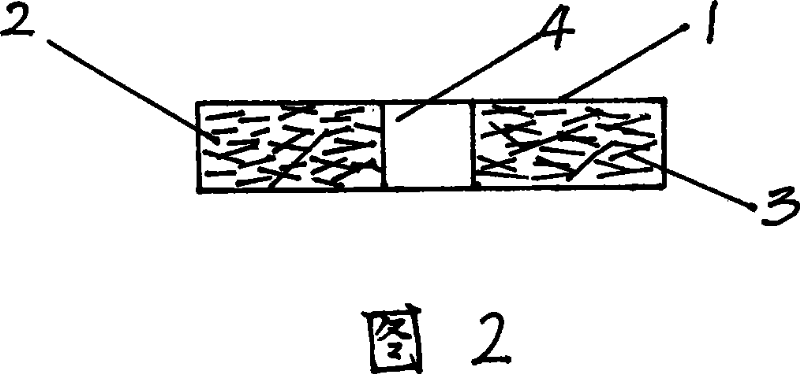

[0029] What represented by Fig. 1-2 is embodiment one of the present invention, and it is made up of 50% wax 2 and 50% asbestos 3 by weight ratio for hot gas lift-off lamp wax block 1; Dimensions: 50×50×10 mm; the diameter of the fastening hole 4 is 10 mm. The hot air lift-off lamp uses the present embodiment as a burning luminous object, which can stay in the air for 7 minutes.

[0030] Its production method is: heating and melting 50% paraffin wax by weight, then adding 50% asbestos by weight,

[0031] Stir evenly, inject into the mold of the wax block used for the hot air lift-off lamp, and open the mold after cooling.

Embodiment 2

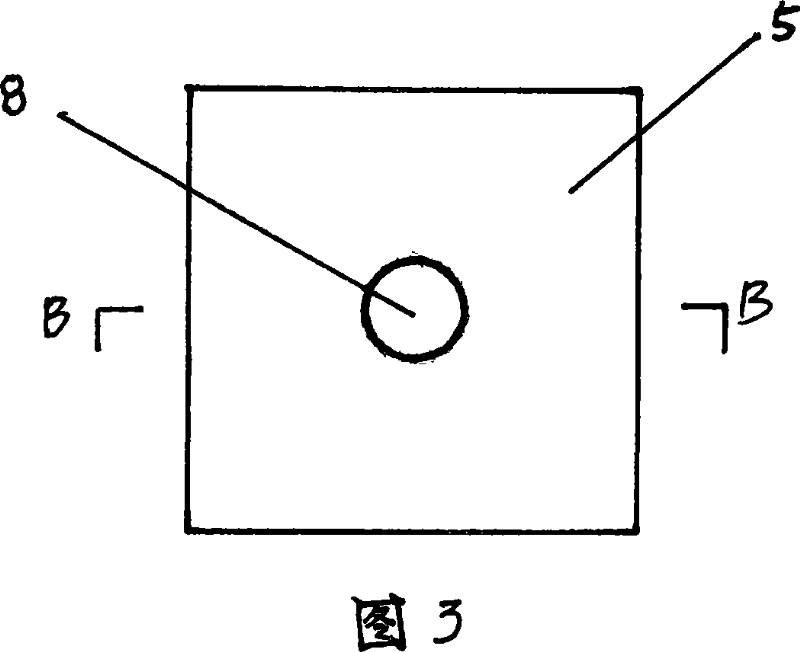

[0033] Represented by Fig. 3-4 is embodiment two of the present invention, and it is made up of 60% wax 6 and 40% glass fiber 7 by weight ratio with wax block 5 for hot gas lift-off lamp; Wax block 5 for hot gas lift-off lamp Dimensions: 50 × 50 × 10 mm; the diameter of the fastening hole 8 is 10 mm. The hot gas lift-off lamp uses the present embodiment as a burning luminous object, which can stay in the air for 8 minutes.

[0034] The preparation method is as follows: heating and melting 60% of the modified paraffin wax, then adding 40% of the glass fiber by weight, stirring the two evenly, injecting them into the mold of the wax block used for the hot gas lift-off lamp, and opening the mold after cooling.

Embodiment 3

[0036] Represented by Fig. 5-6 is embodiment three of the present invention, and it is by weight 54% wax 10, and 43% asbestos 11,3% metal salt chromogenic agent-chlorination Composed of lithium 12; the size of the wax block 9 for the hot gas lift-off lamp: 50 × 50 × 10 millimeters; the diameter of the mounting hole 13 is 10 millimeters. The hot gas lift-off lamp uses the present embodiment as a burning luminous object, which can stay in the air for 8 minutes and can send out a gorgeous red flame.

[0037] Its production method is: heating and melting 54% of modified paraffin wax, then adding 43% of asbestos and 3% of metal salt chromogenic agent-lithium chloride, stirring the three evenly, and injecting hot air into the mold of the wax block used for the lamp In the middle, open the mold after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com